Machine owners who regularly maintain their machines prevent many unplanned downtimes and thus improve the entire production reliability of their facilities. Nevertheless, many users still let their machines run until severe damage has occurred – without ever performing a comprehensive check beforehand. What is important when it comes to inspection and maintenance, and what opportunities does IoT technology offer in this regard? A conversation with Patrick Theiss, head of the After Sales/Service business unit at EMAG.

Oliver Hagenlocher

The monthly number of new registrations of e-cars in Europe is currently increasing – and with it the required quantities for the e-drive components. The example of the supplier Linamar Technology Hungary shows how the production task behind this can be solved effectively. The e-drive specialists have recently invested in EMAG machines for the production of shafts and gears. A conversation with István Bíró, Project leader at Linamar Technology Hungary, about the new solution at the site in Békécsaba.

There is no “one” best method for cleaning or de-coating workpieces. After all, the choice of method comes down to basic conditions and objectives in the production process. In this sense, laser cleaning is not a one-to-one substitute for traditional washing either but does frequently have an advantage.

According to a survey carried out by the digital association Bitkom, roughly six in ten German companies are already using Industry 4.0 applications. However, just 14% of them are using artificial intelligence (AI) to boost their productivity. But getting started with the whole field of data science is easier than many people think. EMAG’s partner anacision is offering a cost-effective Industry 4.0 workshop and compact data analysis packages to help users fulfill their business potential. We talked to Daniel Poodratchi, Head of Product at anacision, about quickly identifying ineffective processes using AI, data-driven production optimization and successful customer projects.

With around 15 percent growth per year, the Czech supplier ZLKL has an impressive success story. Advanced production technologies with automation components play a decisive role in this. For example, around 25 EMAG machines are in operation at ZLKL’s Czech sites. Karel Zeman, Senior Manager Machining at ZLKL, discusses his company’s formula for success.

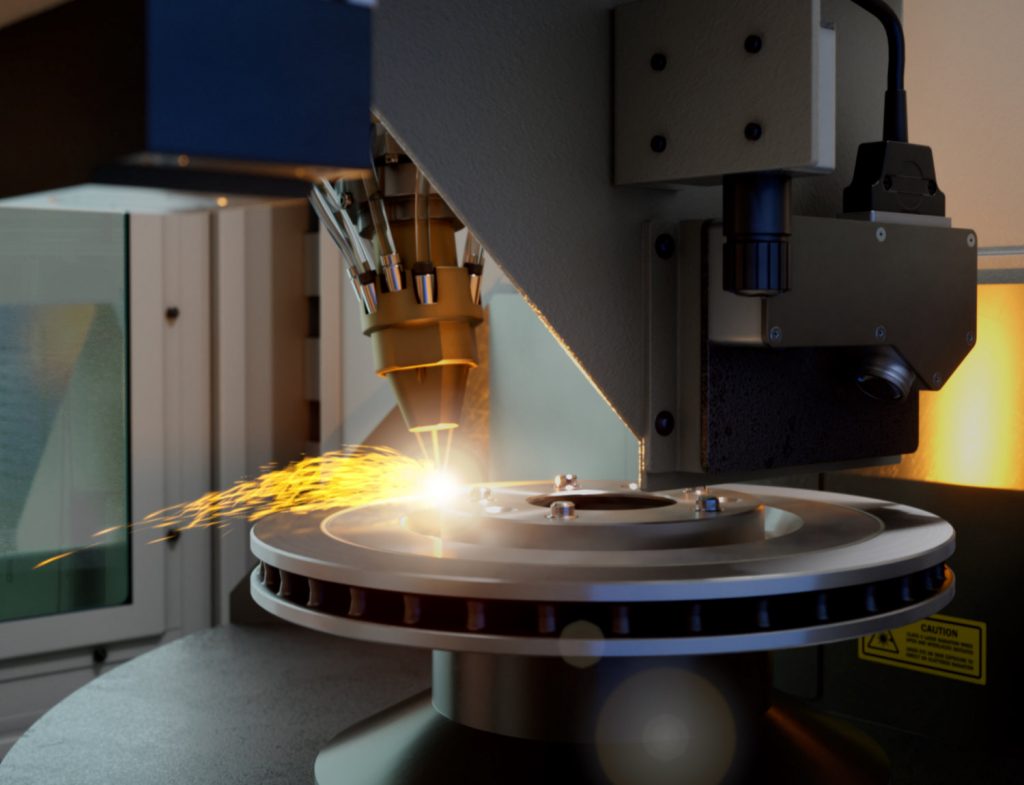

The passenger car brake disk of the future is resistant to wear, resistant to corrosion and does not produce any fine dust – this is made possible by a hard metal coating that is applied to the disk by a laser welding process. The corresponding holistic machine solution is developed by EMAG LaserTec. A conversation with Dr. Andreas Mootz, managing director of EMAG LaserTec, about the benefits of laser metal deposition and the corresponding new machine, ELC 450 LMD.

Mr. Mootz, why are automobile manufacturers currently developing coated brake disks?

There are two main reasons. On the one hand, a great deal of fine dust is produced by conventional brake systems – a topic that has been attracting more and more attention for a while now. On the other hand, the increasing significance of e-mobility plays a role, due to the fact that the brakes of e-cars are rarely used. This is because there is already a sufficient braking effect during the recuperation of the engine. However, brake disks that not used for long periods may under certain circumstances begin to rust. This is why the brake disk technology is currently undergoing a change. For example, hard-coated brake disks are increasingly being used, as they are virtually resistant to wear and corrosion. Furthermore, they produce no fine dust.

How are these disks coated?

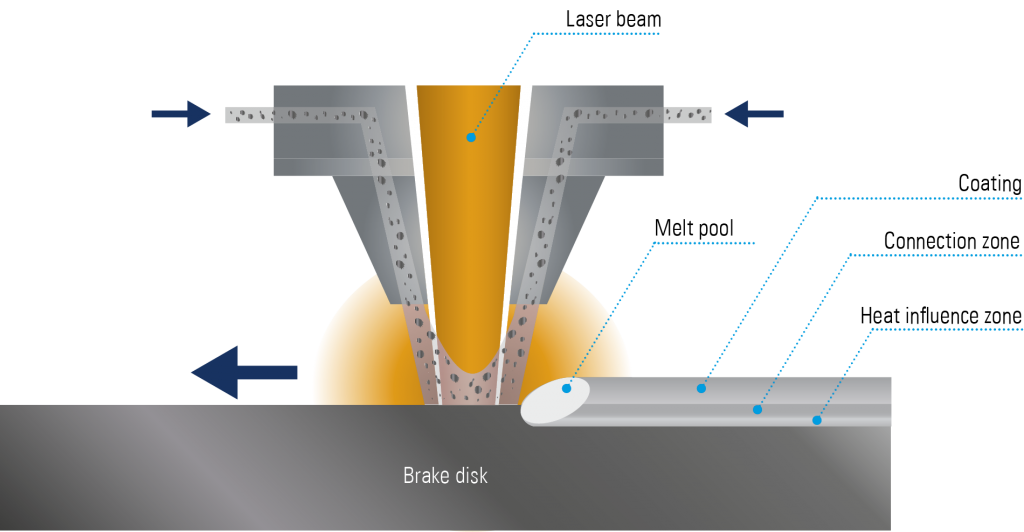

Currently, high velocity oxygen fuel spraying (HVOF) is frequently used. With this method, the coating is shot onto the component at high speed. However, this whole procedure involves high material losses. This is one of the main reasons why we at EMAG LaserTec have been working on an alternative in recent years – laser metal deposition. With this method, a bond layer and the hard metal layer on top of it are applied to the brake disk by a laser welding process. So almost no material is lost.

How reliable is this method?

From the very beginning, our machine development was focused on process reliability. This factor is, of course, indispensable to mass automobile production and we now have the perfect solution ready: the new ELC 450 LMD machine. It contains a turntable with five stations, which each component passes through a total of four times – twice per side as the coating consists of two layers.

What happens at these five stations?

In the first station, the component is weighed uncoated. This value is used as a reference to be able to determine the coating weight later, when the component is weighed for a second time after one pass. In the second station, any work materials and dirt are then removed from the blank by means of laser cleaning. In the third station, induction technology from EMAG eldec ensures an ideal processing temperature. The actual laser coating procedure is then performed in the fourth station. The entire process benefits from the sophisticated design of the laser tool, in which the material powder is fed in through a channel. The material fuses with the disk surface at the melting point of the welding process. As last step, the component is measured and, after two coating passes, is flipped over to coat the second side. Then the described process starts from the beginning again. Finally – after a total of four cycles – the component is unloaded. This combination of high-precision laser coating technology with cleaning and pre-heating processes as well as quality assurance measures, such as weighing, ensures the necessary process reliability.

What role do the upstream and downstream production processes play for the component?

The disk blank is turned beforehand, and a grinding process is necessary after the coating process – both processes can be implemented with EMAG technology. This is where our strength comes into play. At the customer’s request, we provide the complete production solution for the next generation of brake disks from a single source. With our wealth of process expertise, we stand for holistic solutions in numerous areas of application. This will soon also include coated brake disks.

The last question is about where you are right now. Is the development of the machine complete?

The development of the machine with its five stations and the corresponding processes is complete. However, we are currently still conducting tests concerning the coating and the coating process. But there is no doubt that we will be able to offer our customers an extremely efficient solution in the future.

Predictive maintenance, increasing output quantities and decreasing error rates – the performance promises of Industry 4.0 are great, although many users still doubt their feasibility: “It’s all a long way off,” as we often hear. At this point, we want to take a very practical look at this topic: At a major German automotive components supplier, IoT experts from EMAG, and their partner companies EXXETA, intuity, and anacision, have optimized a central production process – with amazing results, such as a significant increase in the production capacity of the EMAG line. A conversation with Andreas Kühne, lead data scientist at anacision, about the current successes of the associated EMAG EDNA technology, and how machine builders are comprehensively digitizing their machines.

As a mechanical engineering company, EMAG is making an important contribution to establishing electromobility: The specialists are developing the production technology that can manufacture central components of the electric motor – on a turnkey basis. A new production line for the rotor shaft of electric cars used by a German components supplier illustrates their approach. The solution was delivered at the end of last year. Here we have a conversation with Andreas Bucher, Key Account Manager at EMAG, and Michael Ihring from EMAG Systems about the reasons for this cooperation.

Particular precision is essential for the e-drive market: Many components require perfect surfaces – this ensures smooth running at the high torques of the electric motor. The example of “tooth flank grinding” with machines from EMAG SU shows how suppliers, general transmission manufacturers and OEMs can implement this requirement: The grinding specialists have, for example, a special axis concept in the G 160 machine that guarantees microscopically perfect surfaces. A conversation with Alexander Morhard from EMAG SU about EMAG SU’s mechanical engineering solutions for tooth flank grinding.

ECM (Electrochemical Machining) is being used for a growing range of industrial applications. To date, deburring is customary, but ECM could replace traditional chip-removal manufacturing processes as a better alternative. In the interview, our two ECM experts Fazli Yilmaz and Franz Gross from EMAG ECM explain what ECM is all about.