For over 50 years, Kordel has developed a variety of drive systems and transmissions used in agricultural and construction equipment, as well as industrial trucks. This is a task that requires both robust machining and precision, simultaneously. The family-owned business with its headquarters in Dülmen near Münster, Germany relies on the competence of its employees, flat hierarchies and a high level of integration with a “state-of-the-art” machine system. For over 20 years, EMAG’s pick-up technology has played a major role at Kordel. More than 17 production solutions from the Southern German machine builders are used at the production sites in both Germany and Poland. The most recent additions are two VLC 200 GT turn-grind centers. Below is a conversation we had with the Kordel Managing Director, Johannes Kordel, about the success of his company, and the important part mechanical engineering has played in it.

Oliver Hagenlocher

For over 30 years, Bäringhaus & Hunger, based in Grünhainichen near Chemnitz, have been active in the part manufacturing industry – experiencing growing success with the production of high-precision turned and milled parts. About 90 percent of orders received at Bäringhaus & Hunger come directly from suppliers in the automotive industry. From almost the very beginning, EMAG has played an important role in this as a mechanical engineering partner, and currently have over 20 machines on the Bäringhaus & Hunger shop floor. How did this partnership develop and why is it still so important today? We spoke with partners, Matthias and Sebastian Hunger, the second generation of the family to run the company, about the secret to their company’s success.

Interprecise Donath GmbH, based near Fürth, Germany, develops and produces rolling bearings that are used in a variety of machines and gears – an extremely precise task that involves just a few micrometers and requires special surface qualities. For about three years, VL vertical lathes from EMAG have been used for this machining, achieving lower unit costs in the soft and hard machining of many components. We sat down for a conversation with Interprecise Managing Director, Christian Witte, about the market challenges and advantages of pick-up technology.

With the introduction of EDNA, EMAG has developed a complete ecosystem for digitizing industrial production. This required strengthening bonds between teams across company boarders – in addition to the EMAG subsidiaries, diverse external digitization specialists were involved. For this reason, we knew that we had to invite several different people to join this conversation: Peter Strohm, Business Development Manager IoT at EMAG, as well as Ricarda Schuhmann and Lukas Siegele from our partner intuit to tell us about the development process, the possibilities offered by EDNA and why they are so happy about receiving this very special award.

The scroll-free turning of rotor shaft sheet metal housings has a number of advantages over the traditional turning process. For one, scroll-free turning provides significantly higher feed rates per revolution, leading to a reduction in overall cycle time. Machine time is also reduced by using the entire cutting edge of the tool – providing the additional benefit of improving tool life. This technology has also proven to achieve significantly better surface qualities.

As the year comes to a close, we’d like to review some of the most exciting events from the past year such as the EMAG Technology Forum and EMO Hannover.

Whenever containers are lifted by trucks, large excavator shovels are swiveled or heavy containers are tilted at production plants, powerful rotary drives are to thank! The number of application examples for this technology is almost unlimited. As market leader in this sector, HKS Dreh-Antriebe GmbH with headquarters in Wächtersbach, Hesse relies on vertical hobbing machines from EMAG Richardon – major gearing is created with their help. These specialists have recently acquired a new machine of this type for their production site in Neukirch, Saxony. In the following interview, HKS Production Manager Mario Vogt explains why they made this investment decision and what technological challenges stand out in this process.

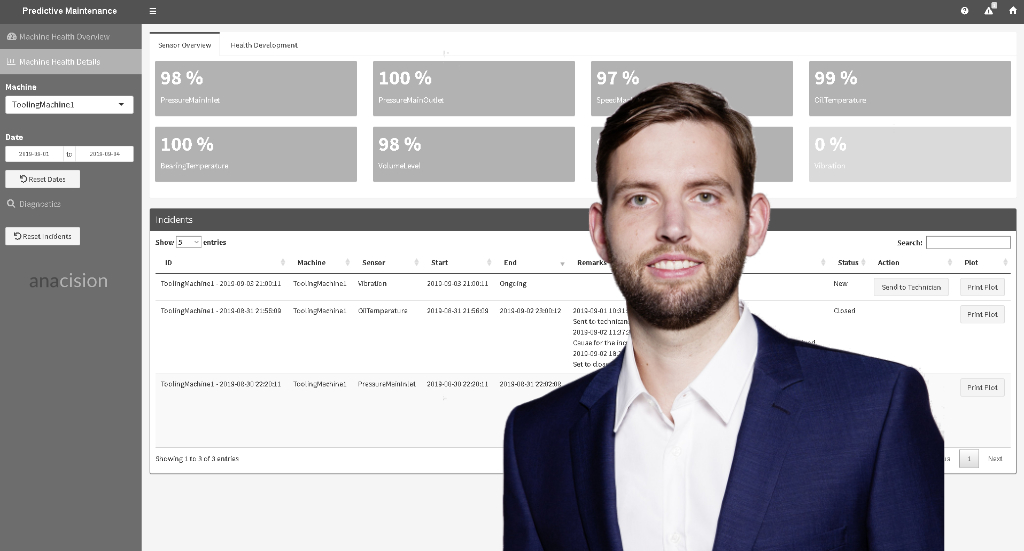

Data analysis and artificial intelligent are essential for the future of mechanical engineering. That is why the EMAG Group invested in anacision Gmbh from Karlsruhe, Germany last year – with the goal of developing AI products and solutions for the mechanical engineering industry. We spoke with Mr. Andreas Kühne, Senior Data Scientist at anacision, about its joint presence at the EMO with EMAG.

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

The production of turbocharger components is one of the most challenging tasks in automotive engineering and EMAG has created a complete line solution that delivers both speed and precision.