EWS Weigele is known for its precision tool holders. What is less well known is the company’s technical standards and vertical manufacutring range – including the hard machining of its own bevel and toothed gears. A modernized VSC 400 DDS from EMAG plays a key role here. In this interview, plant manager Christian Schurr explains why the retrofit of this machine was a decisive step for EWS – technically, organizationally and strategically.

Oliver Hagenlocher (EMAG) in conversation with Christian Schurr (EWS) about the modernized VSC 400 DDS for gear production at EWS

Mr. Schurr, EWS is a specialist for tool holders with exceptional vertical integration. Why do you rely on a VSC 400 DDS for your gear wheel production – and why as a retrofit?

We have a very clear requirement for our production: it must be highly precise, highly available and flexible at the same time – especially for our typical small series of two to five pieces per batch. These conditions also apply to our bevel gear and cylindrical gear production. We therefore wanted a machine that achieves tight tolerances with process reliability, but can also be automated and is available at short notice.

After intensive evaluation, we once again chose EMAG, as we had already had good experience with the VSC concept in the past. Instead of investing in a new machine, we worked with EMAG to retrofit the VSC 400 DDS. The decisive advantage: the system was quickly available, technically outstandingly suitable – and our employees were already familiar with the machine. All this convinced us.

Modernized VSC 400 DDS in use at EWS including tool shuttle

What role did machine availability play in this decision?

A very big one. We needed to resume production as quickly as possible – and that’s exactly what the retrofit achieved. We also work with a high in-house production depth of 90 to 95 percent, from the raw material to the finished product. This means that every machine downtime has a direct impact on our ability to deliver. Thanks to the retrofit, we were able to continue using the existing infrastructure, continue working with minimal training and still achieve the highest production quality.

What specifically characterizes the performance of the VSC 400 DDS?

We use the VSC 400 DDS for the complete hard machining of our gears. For us, process stability is the key feature of the machine. The pick-up principle of the VSC eliminates many classic uncertainties in chuck handling. We remove the workpiece directly via the spindle. This process is reproducible, positionally accurate and is hardly influenced by insertion errors.

In this way, we ensure that we maintain exactly the same tolerances across dozens of workpieces without having to measure each part individually.

This is crucial for our batches and our tolerance specifications. We don’t “measure” quality, we create it in the process.

Automated workpiece transport in the VSC 400 DDS – precision feeding via pick-up spindle and rotary indexing conveyor belt

Retrofitting also means technological upgrading. What measures were implemented on your VSC 400 DDS?

EMAG carried out a complete overhaul of the machine. This includes not only the mechanical overhaul, but above all the technological modernization with new measuring systems and optimized automation interfaces. Integration into our existing production system was particularly important.

In combination with our tool change technology, the Varia quick-change system, we achieve a very high level of flexibility. We can swap one gear for another in just a few seconds – including tool changes. This reduces the machine downtime between two jobs to a minimum.

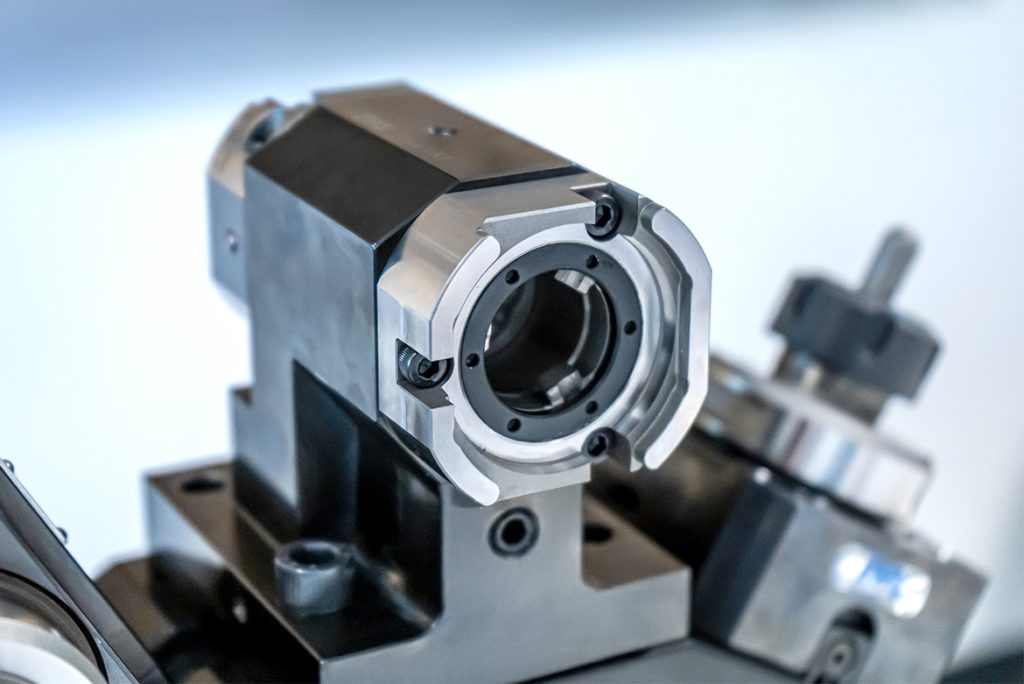

Tool receptors in the Varia quick-change system – prepared for their next use in the automated manufacturing process

Can you explain this quick-change system in more detail?

Gladly. We use the Varia system on our turret machines, which is available in three standardized sizes (VX3, VX4, V5). It allows us to accommodate both static and driven tools and to set them up externally if required. This means that while the machine is running, the next application can be prepared and measured outside the machine – which drastically reduces our non-productive times.

By using digital twins of our tools and holders, we can also prepare the CAM programming accordingly. We know at all times which insert was used for the simulation and thus avoid collisions or incorrect entries in the control system. The actual mechanical conversion takes place via a bayonet lock with a defined torque – quickly, reliably and reproducibly.

Detailed view of a modular tool holder with Varia interface for fast and reliable set-up on turret machines

How important is the digital manufacturing process for your production?

It is becoming increasingly important. The aim is a continuous digital manufacturing process – from design and CAM programming to tool provision. Our tool data and tool holders all exist as digital twins. This automatically derives a setup sequence that the employee can work through. This minimizes sources of error and improves efficiency.

We also use tool shuttles on the machines, which are used to provide the prepared tools. The employee knows exactly which tool has to go to which position – the data is already stored in the system. In this way, even complex changes between different gears can be carried out in the shortest possible time.

How well does the EMAG concept with pick-up spindle and retrofit fit into your batch size structure?

Perfectly. Although EMAG is traditionally active in the automotive sector with higher quantities, the concept also works excellently with small batches – provided it is combined with a suitable tool system and intelligent automation approaches. That’s exactly what we do – and that’s how we manage the balancing act: a high degree of automation with maximum flexibility.

The EMAG system also allows us to place a range of up to three hours on the conveyor belt. Thanks to the pick-up spindle, component handling is reliable and there are no insertion inaccuracies, as can occur with classic robot systems. This significantly increases process reliability even further.

The conveyor belt of the VSC 400 DDS holds workpieces for up to three hours of unmanned operation – ideal for automated small-batch production.

What is the strategic importance of retrofitting from your point of view?

For us, retrofit machines are the ideal way to obtain high-quality production technology quickly and economically. This makes particular sense if the machine structure is still completely intact, but the electronics and controls no longer correspond to the current state of the art. In such cases, the highest productivity level can be achieved again with a manageable amount of effort.

For us, retrofitting is also a clear commitment to sustainability. We extend the service life of the machines and avoid unnecessary consumption of resources without sacrificing modern technology.

Tool storage with Varia inserts in various sizes

Final question: What does “Made in Germany” mean for EWS in 2025?

A great deal. We clearly stand by our location and our own vertical manufacturing range – out of technical conviction. This is the only way we can achieve the high quality and short delivery times that our customers expect. We produce almost everything in-house – from the design to the finished product. The retrofit of the VSC 400 DDS is one component of this philosophy: technologically sensible, economically effective and consistently designed for quality.

Thank you very much for the interview, Mr. Schurr.

Find more information about our retrofit solutions here.

Interested in a new VSC 400 DDS? Learn more about the combined vertical turning and grinding center here.

Aerial view of the EWS headquarters in Uhingen – modern production and development center with high in-house production depth

EWS Weigele GmbH & Co. KG EWS Weigele GmbH & Co. KG, based in Uhingen, develops and manufactures high-precision tool holder systems for CNC machine tools - from static holders to driven tool units and special solutions. The company has a broad technological base and serves almost every common machine interface. With an in-house production depth of up to 95%, EWS consistently focuses on quality "Made in Germany" and maximum flexibility - especially for small batches. The basis for this is an end-to-end digitalized production environment and the use of modular quick-change systems such as Varia.