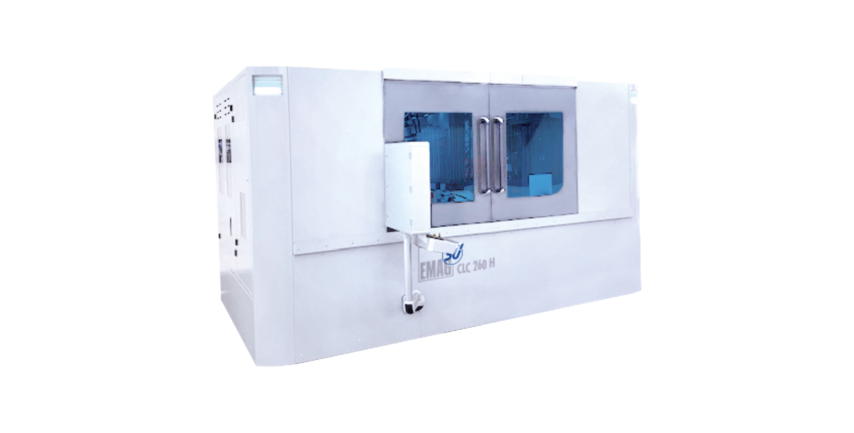

Talladoras por generación horizontales

CLC 260 H / CLC 500 H

- Módulo máx.: 6 / 30 mm | 0 / 1 in

- Ø máx. de pieza: 260 / 500 mm | 10 / 19.5 in

- Longitud máx. de pieza: 1,800 / 2,500 mm | 71 / 98.5 in

CLC Series H: Horizontal Gear Hobbing Machines from EMAG SU

Hob shafts, worm wheels and gear wheels on this innovative and flexible machine. Having a stable structure with hand-scraped tangential axes, these machines include a table and milling head equipped with direct-drive axes. Process using oil, emulsion or run dry. On request, optional equipment for skiving, single-part milling, measuring on the machine, as well as deburring and chamfering is available.

Machining of Gear Wheels, Worm Gears and Long-Toothed Shafts with Excellent Results

Its horizontal configuration allows machining of gear wheels, worm gears and long-toothed shafts with excellent results. Setup and changeover from one workpiece to the next is easy, making these machines suitable for individual parts and small series. In addition, machine options include automation and a steady rest that can be moved to the appropriate position on an additional NC axis.

An optional spindle attachment installed on the milling head of the CLC 260 H horizontal hobbing machine enables worm shafts milling.

Tecnologías

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…

Datos técnicos

Módulo máx.

6 / 30 mm

0 / 1 in

Ø máx. de pieza

260 / 500 mm

10 / 19.5 in

Longitud máx. de pieza

1,800 / 2,500 mm

71 / 98.5 in

| Módulo máx. |

mm

in |

6

/ 30

0 / 1 |

| Ø máx. de pieza |

mm

in |

260

/ 500

10 / 19.5 |