Rifling with the PO 3000 IP: Precise internal contours for gun barrels using ECM rifling

High-precision internal machining with electrochemical processing

Gun barrel production with ECM rifling

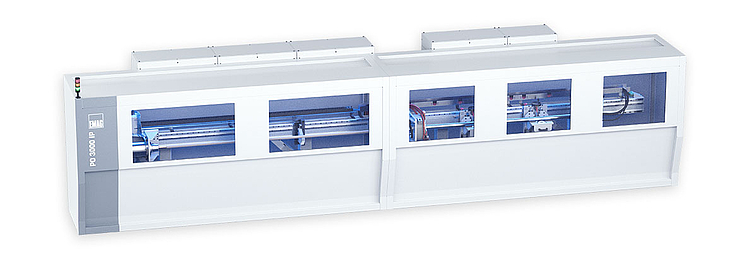

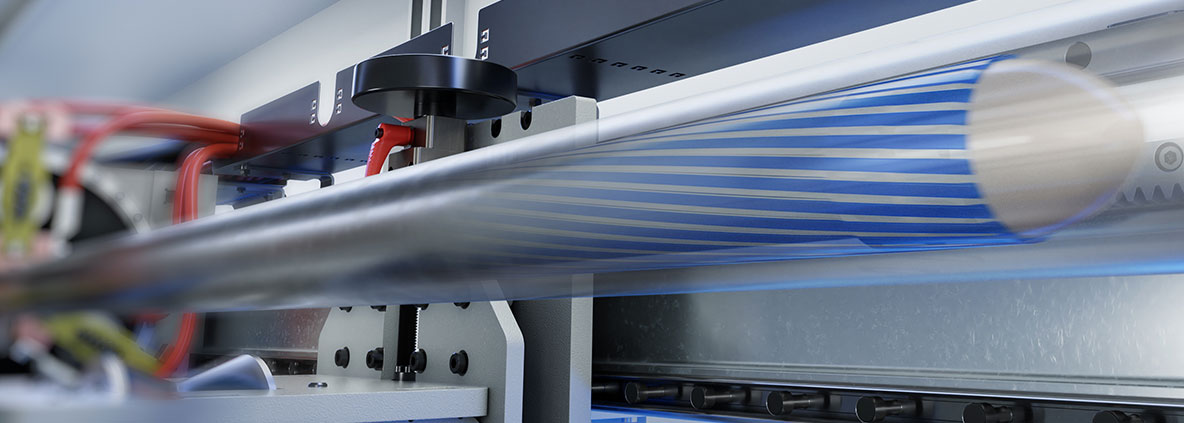

The production of gun barrels with tension-field profiles, also known as rifling, demands the highest levels of precision, repeatability and process reliability. The PO 3000 IP from EMAG ECM offers a solution for the electrochemical internal machining of rifled tubes: delivering stress-free machining, minimal tool wear and maximum reproducibility.

Engineered specifically for the requirements of defense technology, the PO 3000 IP machines tubes with internal diameters of up to 63 mm and lengths of up to 9,000 mm. This makes it ideally suited for manufacturing small- and medium-caliber barrels, such as those used in air defense systems, infantry weapons, helicopters and aircraft.

Advantages of Rifling Machining with the PO 3000 IP

1. Contactless Machining with ECM

Rifling is performed using Electro Chemical Machining (ECM), an electrolytic removal process with no mechanical contact between the tool and workpiece. This ensures:

- No cutting forces or heat effects

- Low cathode (tool) wear

- No stress cracks or structural changes in the material

2. Maximum Geometrical Precision

The rifling contour is defined by the shape of the cathode, achieving accuracies in the hundreths-of-a-millimeter range. Even complex geometries, such as gain twist, can be produced. The process allows full flexibility in adapting caliber, twist length and profile geometry to exact customer specifications.

3. Machining of Hard and Tempered Materials

Unlike conventional processes such as broaching or hammer forging, ECM rifling is independent of material hardness. High-strength, tempered alloys can be machined without limitations.

4. Significantly Reduced Machining Time

A 3 m long tube with a 22 mm internal diameter can be machined in about 35 minutes – dramatically faster than broaching, which requires several hours and tool changes.

5. No Post-Processing Necessary

The process delivers a completely finished inner profile – free of thermal edge zones, with no need for additional measuring or straightening operations.

Why ECM for rifling?

Compared to conventional rifling processes (broaching, cold hammering), the ECM process stands out for its material protection and flexibility:

| Process | Advantages of ECM (PO 3000 IP) | Disadvantages of conventional processes |

| Tool wear | Low wear, constant quality | High risk of wear, high replacement requirement |

| Variety of materials | All conductive materials can be machined | Limited choice of materials |

| Freedom of geometry | Gain twist, asymmetrical profiles possible | Limited profile variety |

| Processing length | 3 m, optionally scalable up to 9 m | Usually limited, high space requirement |

| Post-processing | Not required | Re-finishing and straightening often necessary |

Scalability and Future Viability

ECM technology is inherently scalable to larger calibers and longer pipe lengths – for example, to internal diameters of up to 150 mm and component lengths exceeding 6 meters. This makes it suitable not only for artillery barrel systems but also for applications such as oil drilling technology. With this flexibility, the PO 3000 IP is more than just a solution for today’s requirements – it is a future-proof system ready to support emerging fields of application.

Technical data of the PO 3000 IP

| Parameters | Specification |

| Technology | ECM (Electro Chemical Machining) |

| Area of application | Rifling for gun barrels |

| Workpiece length | 1,000 mm to 3,000 mm |

| Inner diameter | 20 mm to 63 mm |

| Outer diameter | up to approx. 121 mm (larger on request) |

| Feed speed | up to 100 mm/min |

| Cycle time (example 3,000 mm pipe) | approx. 35 minutes |

| Loading | from above, e.g. by crane |

Tecnologías

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

ECM is the ideal technology for machining rifle barrels. The use of a special rifling module in the modular PI machine produces high-precision…