Precise shell processing for 120 mm mortar ammunition

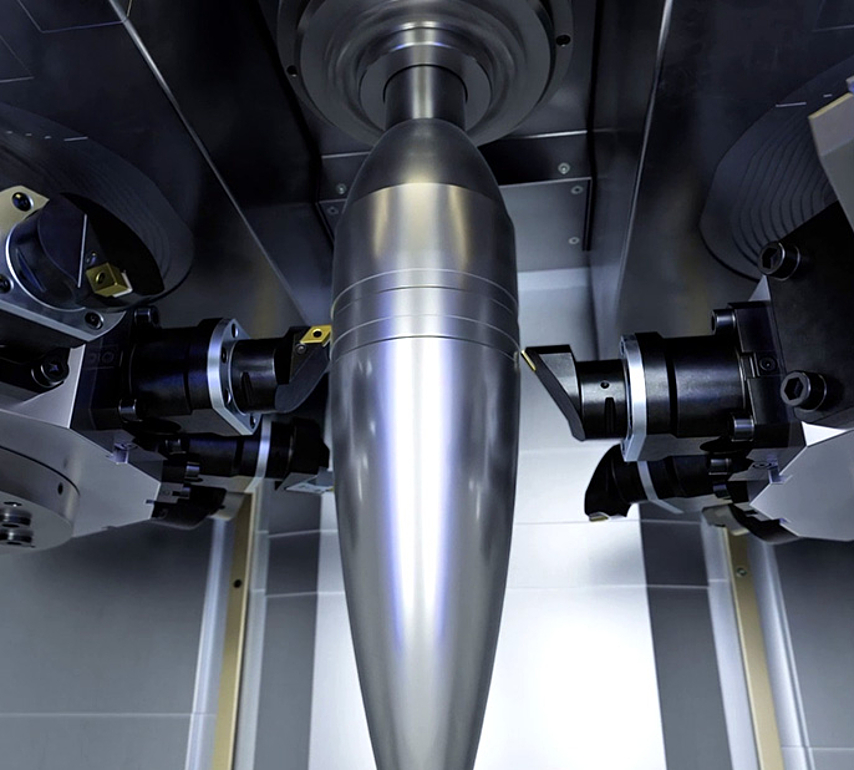

Precision is no coincidence – it is the result of a carefully designed manufacturing process. In producing 120 mm mortar ammunition, the machining of the shell is critcal to ensuring the projectile functions safely and accurately in use. At the same time, cost-effective mass production demands a stable, compact, and automated process.

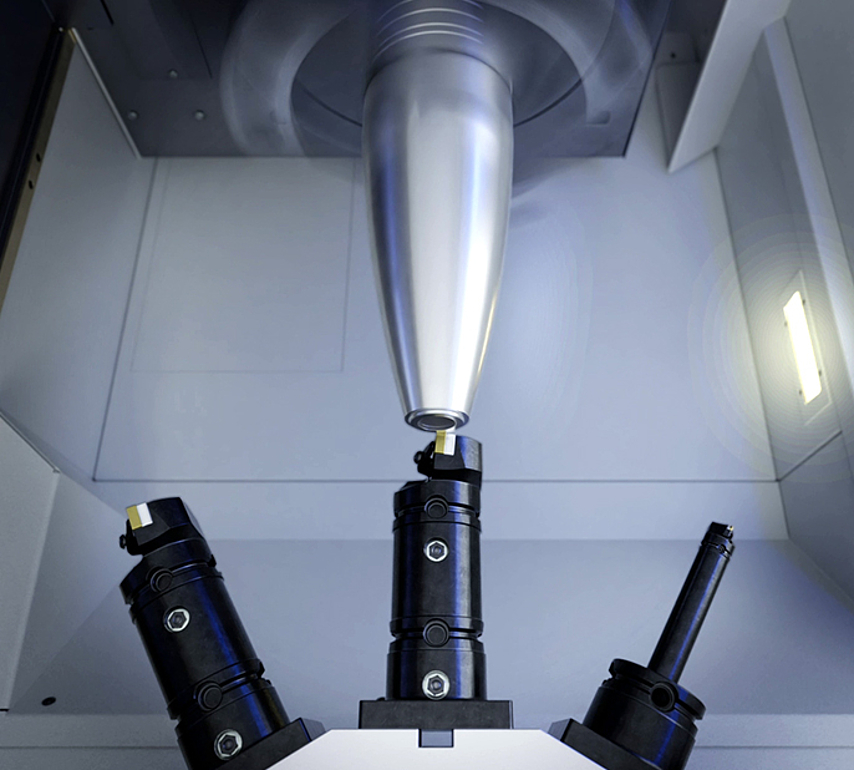

Compact manufacturing system with VT 4, VL 8, and TrackMotion

With the combination of the vertical turning machines VT 4, VL 8, and TrackMotion automation, EMAG offers a comprehensive solution for machining mortar ammunition shells. The shell is manufactured in just two setups—OP 10 on the VT 4 and OP 20 on the VL 8—while the TrackMotion system manages automated part transfer between machines. The result is a compact manufacturing system that reduces cycle times and guarantees reproducible quality.

Customer benefits at a glance:

|

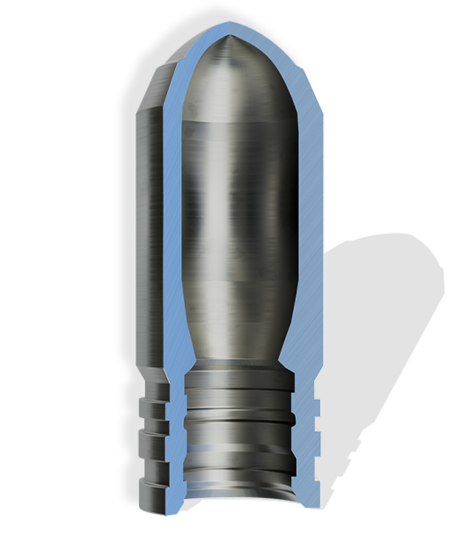

OP 10: Machining on the VT 4

Workpiece: Shell, 120 mm caliber

Machine: EMAG VT 4

Technology: Vertical turning

- Stable machine design for high machining performance.

- Vertical clamping prevents vibrations and reduces chip problems.

- Ideal for initial clamping for precise machining of shells.

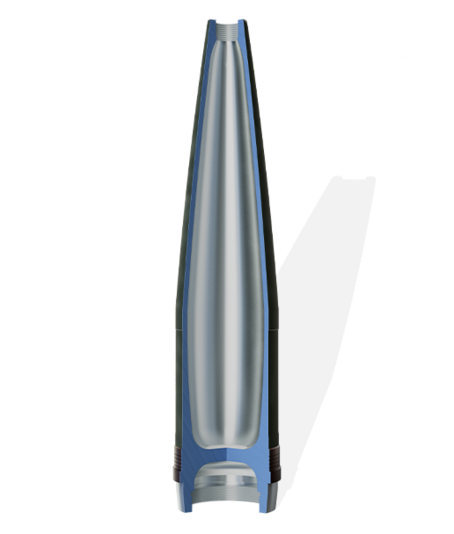

OP 20: Machining on the VL 8

Workpiece: Shell, 120 mm caliber

Machine: EMAG VL 8

Technology: Vertical pick-up turning

- Automatic loading and unloading via pick-up spindle.

- High dimensional accuracy and shape accuracy in series production.

- Perfect for the second clamping for finishing the shell.

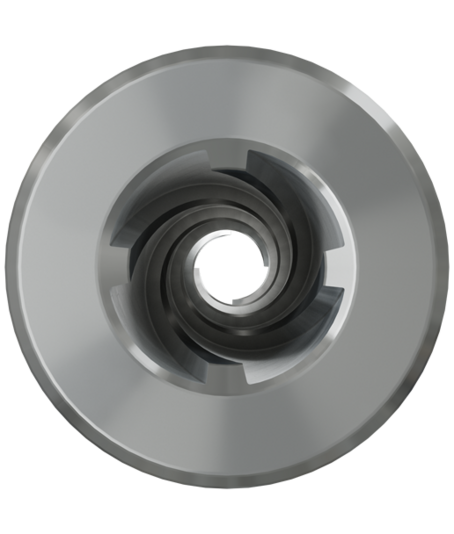

Automation with TrackMotion

EMAG TrackMotion is a modular automation system that can be used to link machines together to form lines. At its heart is the TransLift, a shuttle on a linear axis that transports workpieces quickly and precisely between the VT 4 and VL 8 machines. At the same time, the track serves as a buffer to ensure a continuous flow of parts and avoid machine downtime.

Advantages for ammunition production:

- Shorter cycle times thanks to fast parts transport.

- Space-saving integration without separate interlinking conveyors.

- High process stability, as manual intervention is no longer necessary.

- Flexibly expandable if additional processing steps or calibers are to be manufactured.

Machines

(2) máquinas encontradas

Workpieces

Technologies

Tecnologías

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…