Experience the new generation of EDNA Feature Correction and EDNA Production Status.

EDNA Feature Correction is a core component of EDNA ONE and enables the manual or automatic adjustment of production features in real time. This ensures that product quality remains stable over the long term and process deviations can be corrected immediately.

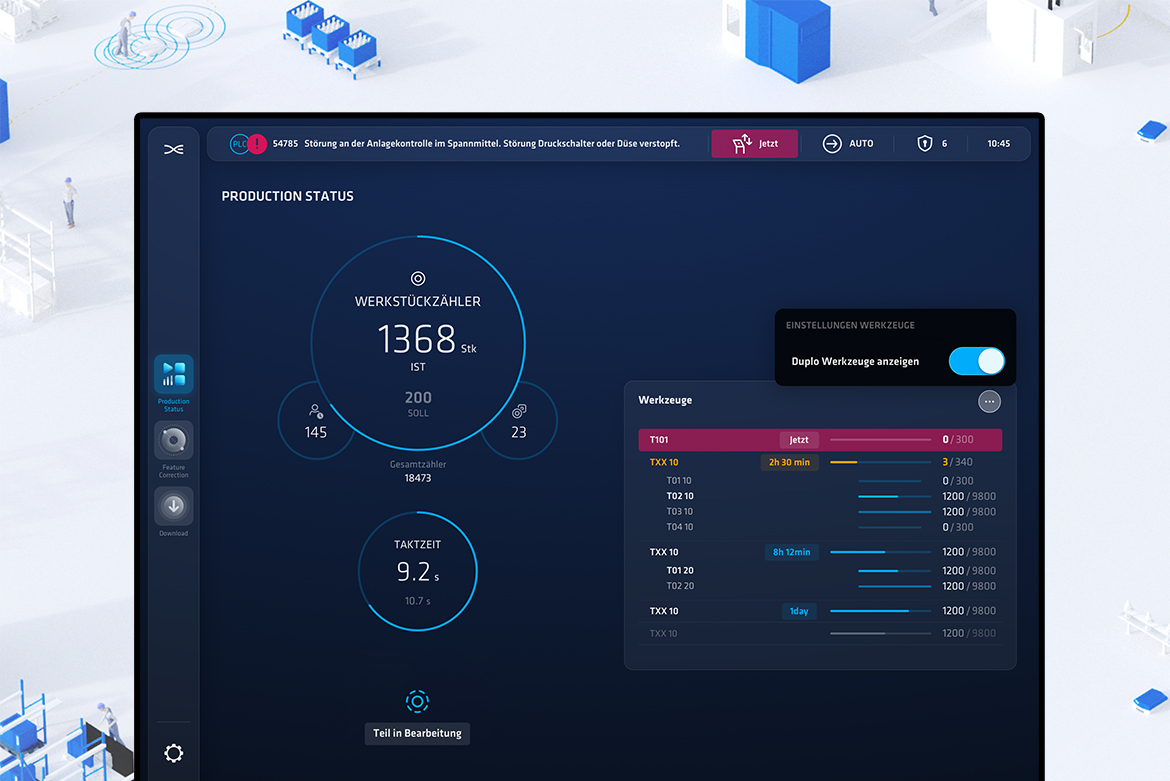

EDNA Production Status is a central module of EDNA ONE and displays the current status of a machine as well as the overall production progress in real time. Operators receive a clear overview of active programs, upcoming work steps and possible downtimes. This makes machine operation more transparent, reaction times are reduced and production can be controlled much more efficiently.

Optimization of tool management: Precision tool change prediction

One new feature is the standard integration of tool change prediction. This function calculates the expected time for a tool change based on current usage and displays this information in real time:

- Conversion of the abstract tool life unit into concrete time specifications (hours, minutes, seconds)

- This enables early planning of tool changes

- Minimization of downtimes through timely provision of replacement tools

- Widget in the status bar for an immediate overview in all EDNA apps

The image shows the new tool change prediction function with production status display (workpiece counter and cycle time).

Extended functionality of the EDNA Production Status App for Duplo tools

The display and management of Duplo tools (sister tools) has been extensively revised technically:

- Clear visualization of all available sister tools on the turret

- Precision display of the remaining tool life for each individual Duplo tool

- Display of the total tool life of a Duplo tool group

- Full consideration of all sister tools in the tool change prediction

- Display/show additional information for Duplo tools as required

These optimizations enable machine setters and machine operators to monitor the status of all tools on the turret with greater precision and make it easier to plan tool changes in advance.

The interface shows the new settings dialog with the option “Show Duplo tools”.

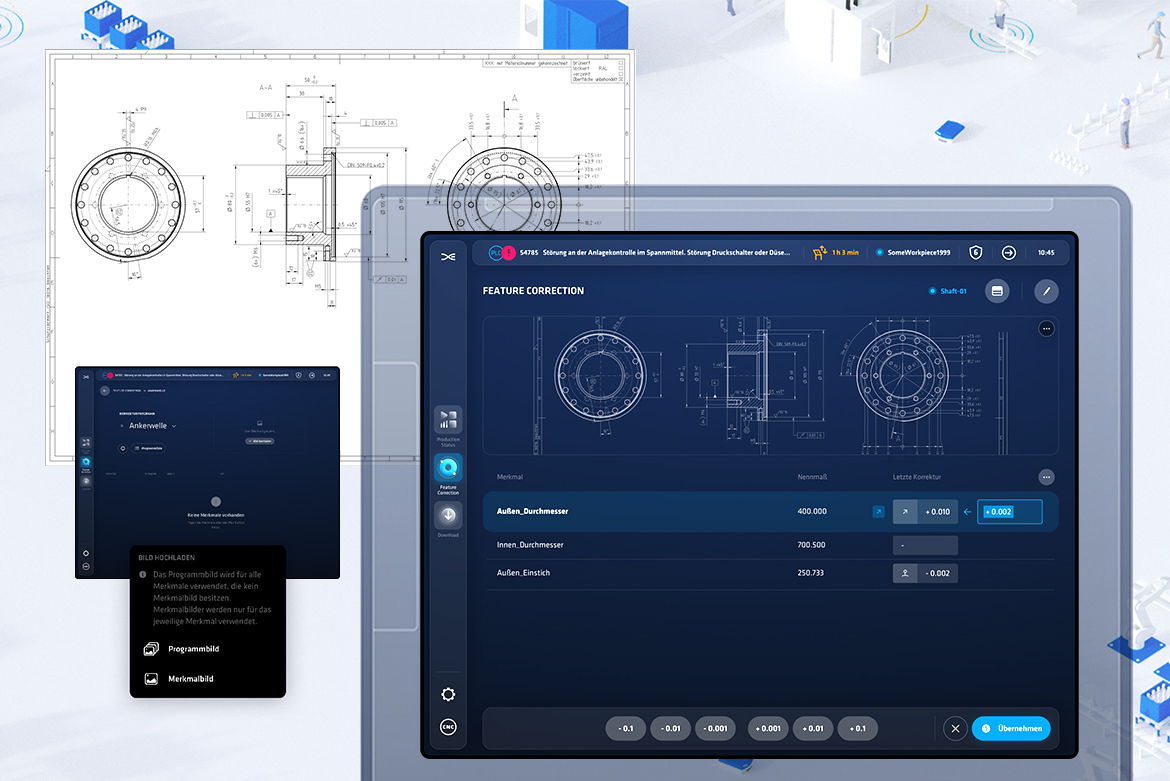

Direct connection of internal and external measuring systems for feature correction

A key step forward is the complete integration of different measurement sources. With EDNA Feature Correction, both the machine’s internal measuring probes and external measuring stations can be integrated. This means that all relevant measurement data flows directly into the process control without the need for detours or manual data transfer.

The user decides which source is used for each feature. This opens up completely new possibilities for closed-loop operation, in which process data is converted into corrective measures in real time.

EDNA Feature Correction combines internal and external measurement data for automatic process correction. Measurement sources can be easily assigned and displayed in common trend graphs. This creates a precise picture of the manufacturing process.

Trend visualization for correction values during feature correction (EDNA Feature Correction)

The previously optional trend visualization for correction values is now integrated as standard in release V18. This function graphically records the design and development of the correction values entered:

- Visualization of manually entered correction values in a graph over time

- Visualization of the wear progression of tools over defined periods of time

- Configurable views for manual entries, automatic corrections or the sum of both values

The trend visualization supports machine operators in identifying wear patterns and enables proactive corrective measures based on empirical data.

The new graphical trend display provides a much better overview of the process history. Several sources can be displayed simultaneously or combined into an aggregated curve. This makes trends, deviations or systematic shifts visible at an early stage – an important prerequisite for recognizing wear, temperature drift or tool deviations in good time and taking countermeasures.

The trend visualization for correction values shows the progression of tool corrections over time in a clear diagram.

Clear visualization through individual feature images

An overview is crucial in day-to-day work. That’s why EDNA Feature Correction now allows individual images per feature.

Each feature to be corrected can be displayed with its own sketch or a component section – this makes assignment easier and reduces operating errors. Optimized fonts and an improved status bar round off the new user interface.

The extended trend graph shows correction data from internal and external sources. Individual or total curves can be flexibly displayed and individually configured.

With these innovations, EDNA Feature Correction becomes a central building block for data-based process control in batch production.

The close link to measuring systems, the improved visualization and the tool change prediction create the basis for higher dimensional accuracy, less scrap and even better transparency in production.