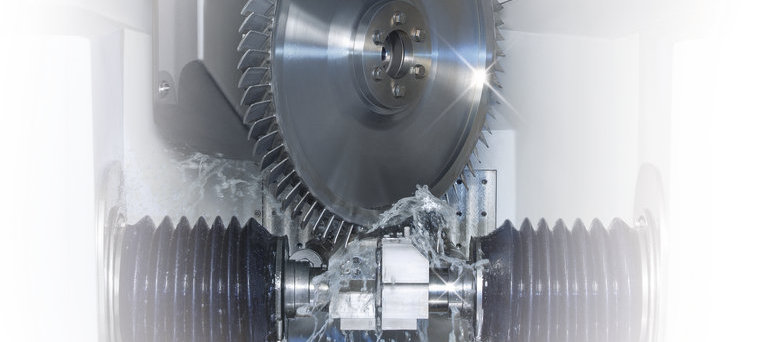

The insertion of field rifling profiles into a barrel – such as those used in sporting rifles – is a very demanding task. The complex internal geometry is difficult to achieve using conventional cutting and forming tools and must be manufactured with extreme precision. While forming processes are often used, they require high capital investment and generate additional process costs. Electrochemical machining (ECM) from EMAG offers an alternative: a fast and effective process that delivers high-precision surfaces. In this interview, Daniel Plattner, Technical Sales Manager at EMAG ECM, discusses the possibilities of this innovative production method for rifling.

ECM

ECM is an innovative technology for machining the barrels of sporting guns. A special rifling module is used in the PI machine. The result is a highly precise and homogeneous field rifling profile for short and long barrels.

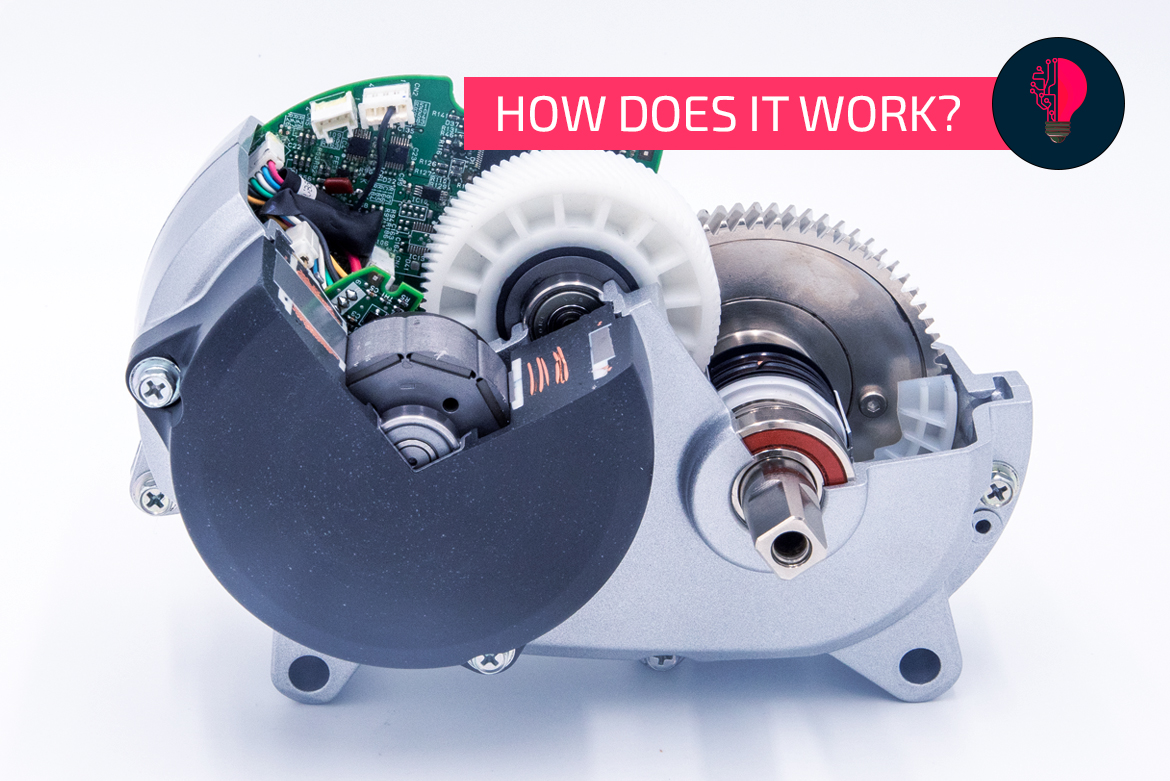

The e-bike market continues to boom – even if manufacturers have recently been unable to match the record figures from the pandemic. Nevertheless, around 1.6 million e-bikes were produced in Germany in 2023. In light of these large figures, it is particularly interesting to take a look at the central component: how exactly does the e-bike motor work, what characterizes its production and what changes are in store for the future?

Sabatti Spa is a renowned family business whose origins go back 350 years with the gunsmith Ludovico Sabatti, is deeply rooted in the tradition of gunmaking. The actual company was founded in the post-war period by Antonio Sabatti and has since built a reputation for precision and craftsmanship. Under the direction of Emanuele Sabatti, the grandson of the company founder, Sabatti Spa has expanded its product range from simple gun parts to high-quality over-and-under shotguns, double-barrel shotguns and carbines. Manuel Steinhauer had the opportunity to interview Emanuele Sabatti, a visionary and technology enthusiast, who has led the company into the modern world of firearms technology without losing sight of its rich tradition and centuries-old heritage. Today, Sabatti Spa is at the forefront of innovation in firearms manufacturing, balancing time-honored craftsmanship with modern technology, making the company one of the leading names in the industry.

ECM (Electrochemical Machining) is being used for a growing range of industrial applications. To date, deburring is customary, but ECM could replace traditional chip-removal manufacturing processes as a better alternative. In the interview, our two ECM experts Fazli Yilmaz and Franz Gross from EMAG ECM explain what ECM is all about.

Networking @ EMO:

Series of interviews with the experts at the EMAG Group with whom you can exchange views at the EMO

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. Yet, we are convinced that not only smart technologies are important, but above all, so are smart people—and they must be brought together to talk to one another.

That is why we will not only focus on networked technologies at the EMAG Group’s booth, but also on networking with our visitors.

In order to let you look ahead and find out whom you absolutely should talk to at the EMO. In the coming weeks, we will regularly interview our experts who will also be attending the EMO in Hanover.

One aspect that is often left out of the discussions about e-mobility is the corresponding transformation in car production: Planners must establish new solutions that enable efficient and holistic manufacturing of “e-components” in significantly higher unit volumes. EMAG Systems is prepared for this!

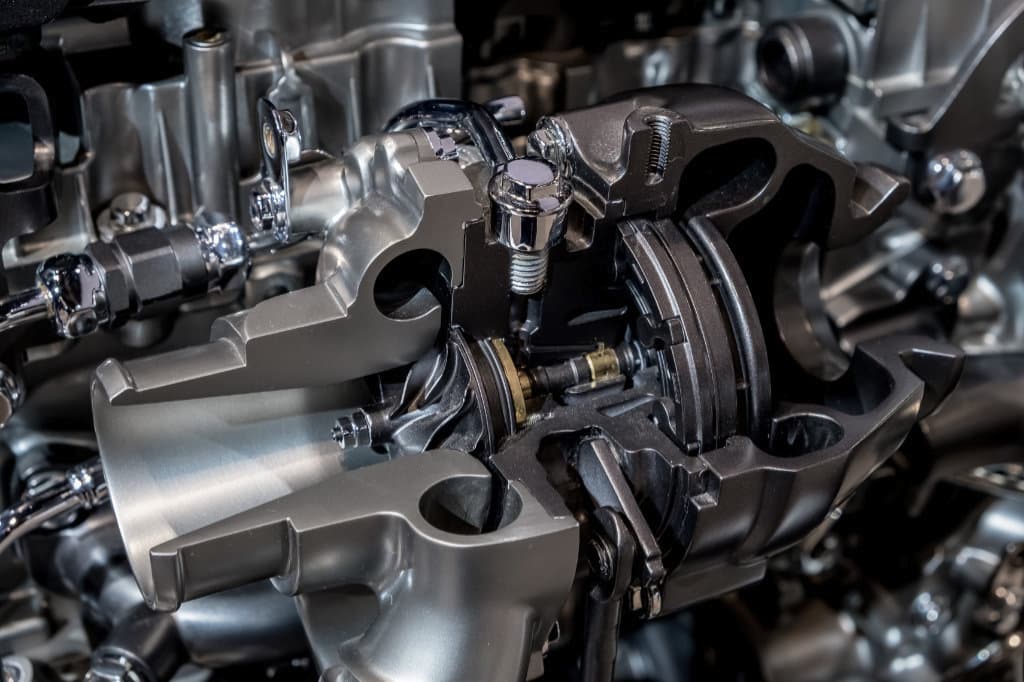

Historically, the power of a car’s engine was dependent on the number and size of cylinders – today, that’s a thing of the past! Electronic engine control, turbochargers or compressors are responsible for the overall performance. The turbocharger has a particularly important role—a Swiss invention dating back to 1925, the turbocharger was used to considerably increase engine power. What distinguishes this component, why is it increasingly important and what are the benefits of using electrochemical machining? —Five interesting facts about turbochargers:

When precision counts in electrochemical machining, the tool cathode plays a significant role: Its shape determines the removal of material at the workpiece. Therefore, its design and precise production is a particularly important machining task in the micrometer range. For its development, EMAG ECM therefore has a large development area with a largely digital workflow.

Electro-chemical machining (ECM) is a fascinating production method, because the technology involves virtually no workpiece contact: A direct current, or pulse, is used to polarize the workpiece positively, to create an anode, and the tool negatively, for the cathode. An electrolyte solution flows between the two, and metal ions detach from the workpiece. The components are not exposed to any mechanical or thermal stress during the process.