An interview with Peter Gröner, Product Manager Business Unit Turning at EMAG, about the new MSC 5 DUO turning machine and its answers to current challenges in machining production.

Mr. Gröner, the new MSC 5 DUO will be officially presented for the first time at EMO 2025 in Hanover in September. What specific market requirements led to the development of this machine?

Our customers’ requirements have changed significantly in recent years. We are seeing increasing cost pressure, particularly in the area of soft machining. At the same time, skilled workers are becoming scarcer and energy costs are rising. This combination requires machines that generate more output with fewer personnel and work more energy-efficiently. The MSC 5 DUO addresses precisely these points. It is a two-spindle, front-loading lathe that combines high productivity with low capital investments. The concept is based on our many years of experience with the MSC series, the first machine of which was launched back in 1982.

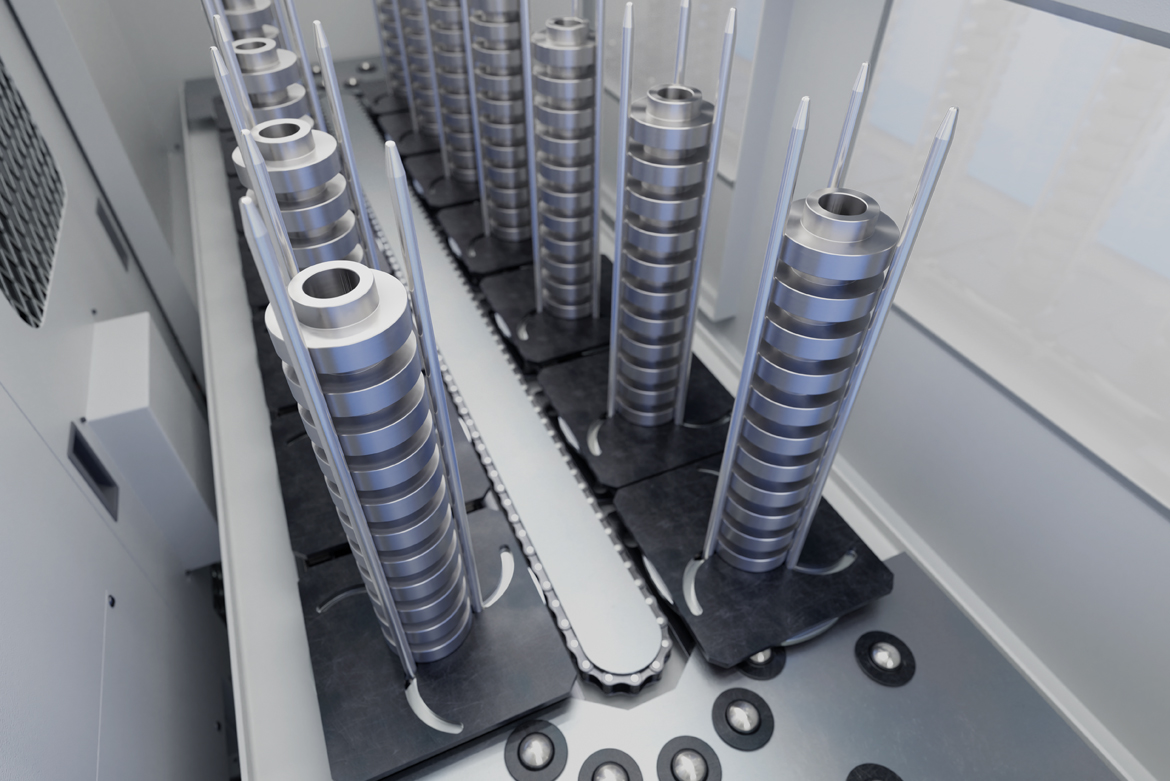

MSC 5 DUO from EMAG with compact design and integrated stacker system for autonomous / unmanned production.

The MSC 5 DUO is part of the EMAG Classic series. What characterizes this product line and how does it differ from the other machine series at EMAG?

The Classic series combines essential machine capabilities with cost efficiency. We offer proven EMAG technologies with a clear focus on specific machining requirements – in the case of the MSC 5 DUO, specifically on high-productivity soft turning. While our modular and customer-specific machines offer a wider range of options and customization options, with the Classic machines we concentrate on what is absolutely necessary. This gives our customers exactly the functionality they need for their application without paying for features they may not use. For example, the MSC 5 DUO costs significantly less per spindle than comparable models in our higher product lines, but offers the same productivity for standard soft turning applications.

Let’s move on to the technical details. Which design features of the MSC 5 DUO make a particular contribution to increasing productivity?

The key is the split-bed design, in which the work areas of the two spindles are mechanically decoupled from each other. This prevents the transmission of vibrations during simultaneous machining and ensures consistent dimensional accuracy on both spindles. The main spindles are designed with a maximum motor speeds of 4,500 rpm and offer an output of 5.5 kW in continuous operation or 7.5 kW for up to 30 minutes. A more powerful version with 7.5 kW (continuous operation) and 11 kW (30 min) is available as an option. Particularly important for machining quality: we have implemented a constant torque in the speed range from 1,125 to 4,500 rpm, which ensures consistent cutting performance for different materials and machining requirements.

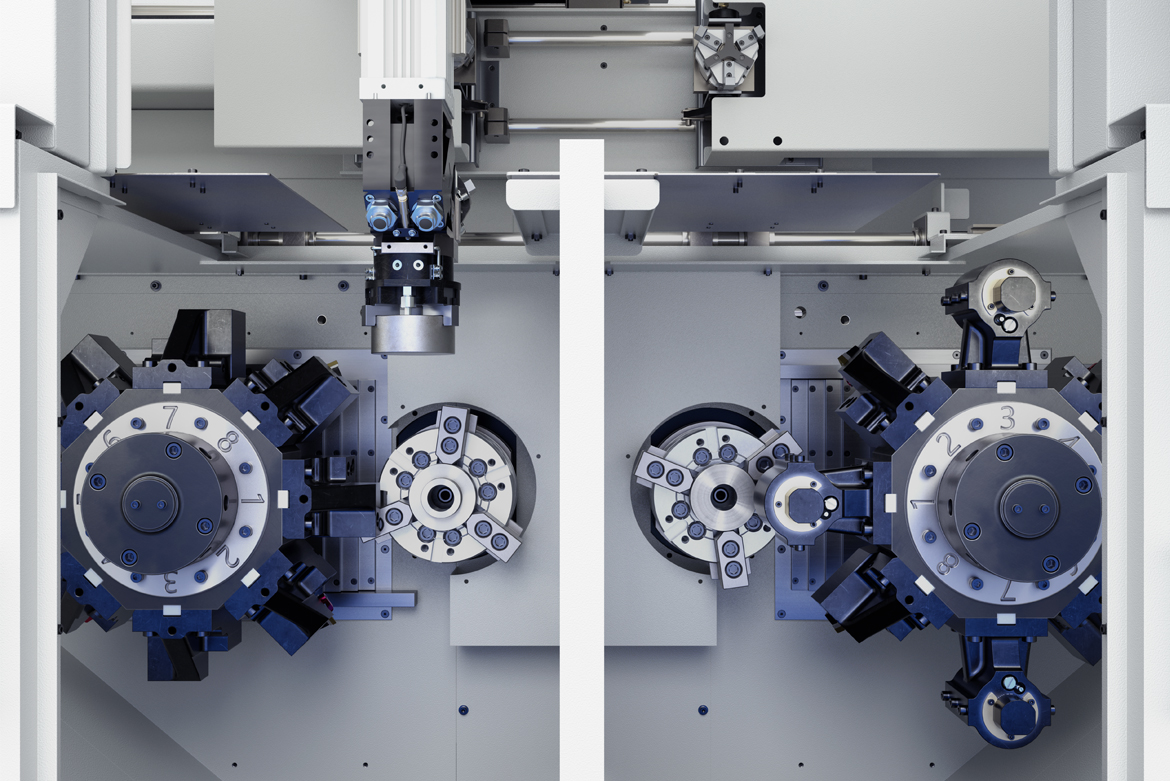

Work area of the MSC 5 DUO with two A2-5 main spindles (4,500 rpm) and BMT tool turret systems. The split-bed design prevents vibration transmission between the spindles.

The two servo-controlled turrets, each with 8 tool positions, are the heart of the machine. The BMT interface allows it to accommodate boring bars with a diameter of up to 40 mm for internal machining and tools with a shank of 25 x 25 mm for external machining. The servo-controlled indexing in combination with hydraulic clamping enables short tool change times with high positioning accuracy.

Non-productive times play a decisive role, especially in batch production under cost pressure. How does the MSC 5 DUO address this aspect?

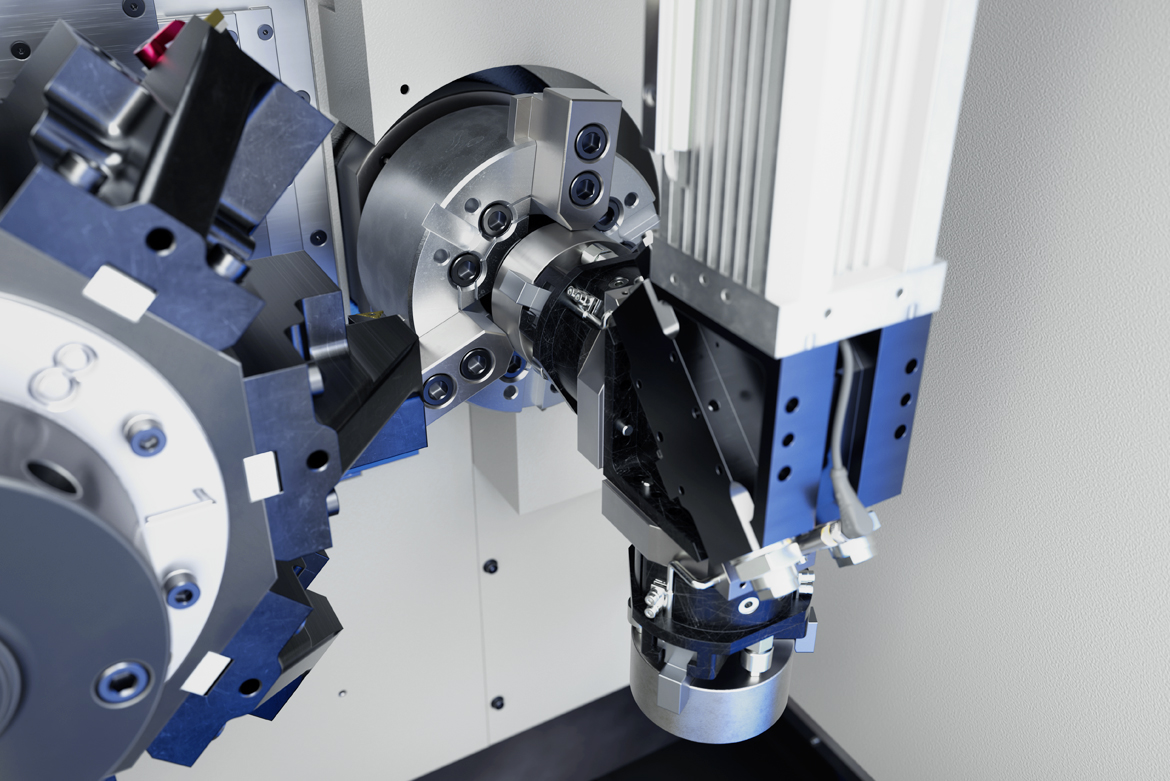

A key element is our 3-axis gantry loading system, which is fully integrated into the machine control system. It handles the automatic loading and unloading of workpieces and is characterized by fast loading/unloading times. A parts turner also enables the complete machining of workpieces from two sides within one machine, which considerably simplifies the material flow. Another important aspect is our compact stacking storage system, which is integrated directly into the machine. This stacker system for raw and finished parts requires no additional space and can be flexibly adapted to different workpiece geometries. Depending on the workpiece size, sufficient components can be stored for several hours of autonomous production, which is particularly important in low-manned production.

Servomotor-driven 3-axis gantry loading system when loading the spindle

How does the control technology support the operator in using the machine efficiently?

MSC 5 DUO is equipped with a FANUC 0i-TF Plus controller. This is specially tailored to turning applications and offers an optimal price-performance ratio. It can control up to 15 axes in a single-channel system and 18 axes in a dual-channel system, which is particularly important for our twin-spindle machine. A key advantage for the user is that the control system allows parallel programming during machining. This means that the operator can prepare the next program while the machine is still producing. The control system also offers extensive process monitoring options.

Chip removal and coolant management are often underestimated factors for process stability. What solutions does the MSC 5 DUO offer in this area?

The cooling lubricant management system has been specifically designed to meet the requirements of batch production. Several precision-aligned coolant nozzles ensure an effective cooling system in the cutting area. The optimized flushing effect ensures reliable chip removal even with difficult materials such as long-chipping materials. This has several direct effects on economic efficiency. Firstly, the improved cooling system and lubrication lead to longer tool life, which reduces tool costs. Secondly, we achieve higher surface qualities, which can simplify or even eliminate subsequent machining steps. And thirdly – particularly important for autonomous production – reliable chip removal significantly reduces the risk of machine downtime due to chip problems.

Ease of maintenance and service accessibility are important aspects for the total cost of ownership. How has EMAG solved these issues with the MSC 5 DUO?

We have placed great emphasis on easy servicing in the design. All relevant service components are easily accessible. Tools are changed ergonomically from the front, which minimizes set-up times and makes work easier for the operating personnel. The clear fault diagnosis of the control system enables quick troubleshooting if a problem does occur. These measures reduce downtimes for maintenance work to a minimum, which increases machine availability and thus boosts productivity. The aspect of worldwide service should also not be underestimated. As a customer of the MSC 5 DUO, you have full access to the worldwide EMAG service network – an important factor especially for machines used in batch production, where every day of downtime incurs high costs.

The stacking storage system for raw and finished parts integrated into the MSC 5 DUO enables hours of autonomous production without operator intervention.

Finally, a look into the future: How is the MSC 5 DUO positioning itself in the context of the increasing digitalization and networking of production systems?

The MSC 5 DUO is designed for integration into digital production environments. It can be easily connected to MES and ERP systems via standardized interfaces. The machine supports the acquisition of production and machine data, which can be used for analyses and to optimize manufacturing processes. Looking to the future, we see this machine as an elementary component in automated production lines in which several machines are linked to form a process chain. The concept of the MSC 5 DUO with its integrated automation system fits perfectly into this picture. It is important to us that we do not create complexity for the sake of complexity. The MSC 5 DUO offers precisely the technical functions that our customers need for their specific production tasks – no more and no less. We consider this focus on the essentials to be a decisive factor in remaining competitive in the future.

Mr. Gröner, thank you very much for the informative interview and the detailed insights into the MSC 5 DUO.

Peter Gröner is Product Manager of the Turning Business Unit at EMAG. With his many years of experience in the design and development of CNC lathes and their market launch, he played a key role in the design of the new MSC 5 DUO. His focus is on the optimization of manufacturing processes in terms of cost-effectiveness and resource efficiency.