“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

Interview with Nikolas Meyer, EMAG LaserTec

Mr. Meyer, EMO 2019 is almost upon us. Are you ready?

Absolutely! My team and I are looking forward to our time in Hanover. It will involve some very intense and strenuous days, but the setting and the crowd at the EMO are simply unique and that makes up for all the effort that comes with a trade show of this size.

What are you looking forward to personally?

Firstly, I want to see how people like the concept of the EMAG Group’s stand, but I have few concerns on that score. We’ve put together a genuinely exciting package comprising of modern manufacturing technologies alongside solutions for the major trends of our age: digitalization and electromobility.

Secondly, I’m also interested in my area of specialization, laser technology. EMO is the ideal place to interact with other experts.

Does EMAG LaserTec have anything new to share in that area?

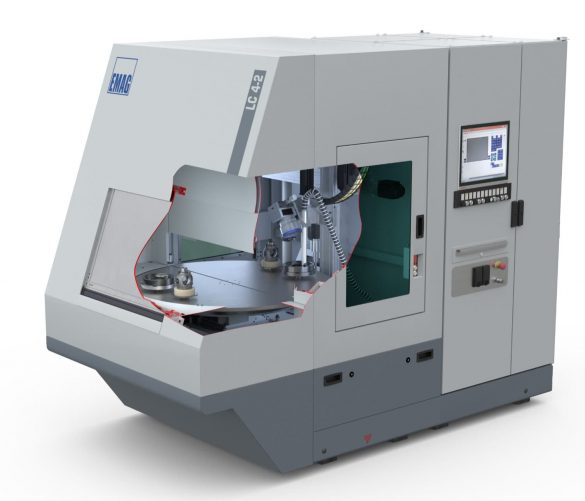

Yes, something brand new in fact: the LC 4-2, our new laser cleaning machine.

New? EMAG LaserTec has used laser cleaning for years—what’s new about this machine?

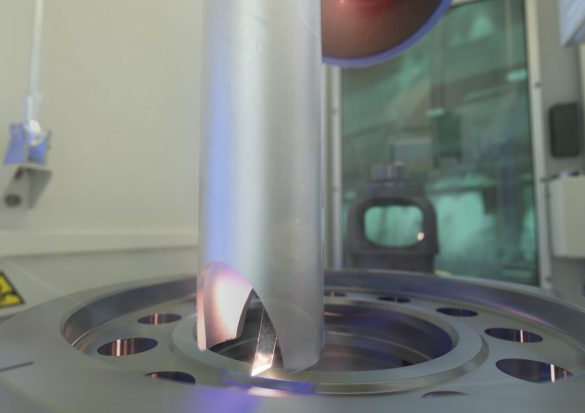

It’s true that we’ve used this technology for many years to remove impurities from components prior to laser welding. In the case of the ELC 250 DUO laser welding machine, for example, the laser cleaning element is built in. We also have separate laser cleaning stations. However, these stations have always been custom solutions that needed to be redesigned for every new application. The LC 4-2 is our first standard solution for universal use. That saves on development costs and translates to a more attractive price for customers.

Does this mean that in the future the LC 4-2 will be used as the standard laser cleaning solution in laser welding systems?

The LC 4-2 is designed for components up to 200 mm in diameter. From now on, we will use the LC when working with components in this size range.

But the LC 4-2 is not just for use with laser welding systems. It can also be implemented as a stand-alone machine for cleaning only. It features a rotary indexing table, which guarantees easy loading and very safe operation, and all the other components, such as laser source and filter system, are already included in the LC 4-2 package.

The optics can also be NC-controlled if required, allowing various components or part families to be cleaned without major setup work. It could hardly be any easier.

One more question for you: why should we visit the EMAG Group’s booth at the EMO?

To see the LC 4-2 live, of course! Otherwise, if people out there for some strange reason aren’t interested in laser cleaning or laser welding, I can only mention our other highlights: Digitalization and umati, manufacturing solutions for electromobility and modern transmissions, production line concepts by EMAG Systems and lots more. Even so, the LC 4-2 will be THE highlight of EMO 2019—for me at least.

Thank you for this interview!