With the introduction of EDNA, EMAG has developed a complete ecosystem for digitizing industrial production. This required strengthening bonds between teams across company boarders – in addition to the EMAG subsidiaries, diverse external digitization specialists were involved. For this reason, we knew that we had to invite several different people to join this conversation: Peter Strohm, Business Development Manager IoT at EMAG, as well as Ricarda Schuhmann and Lukas Siegele from our partner intuit to tell us about the development process, the possibilities offered by EDNA and why they are so happy about receiving this very special award.

Mr. Strohm, let’s start with some background – how do you even begin to launch a project as huge as EDNA?

Peter Strohm: It definitely is a challenge. For example, just look at the impressive structure and performance we have at EMAG: we develop state-of-the-art turnkey manufacturing solutions. To do that, we utilize the experience of a variety of subsidiaries that contribute their individual expertise. Obviously, an ecosystem for digitizing industrial production has to be compatible with all EMAG machines and production solutions. Therefore, we hosted a variety of workshops with experts from our different subsidiaries to discuss requirements and coordinate every development step.

How is it possible that a solution can run smoothly on a turning center, an induction hardening machine and an ECM machine?

Peter Strohm: The magic word is “modularity.” In a manner of speaking, we created a set of building blocks that we modify for each application and production system. Where the associated control panel is concerned, these changes can be made very quickly. Of course more extensive work is needed on the actual IoT core of EDNA—the brain of the machine that we call CORTEX. Here we have to implement integration with various machine controllers from Siemens, Fanuc or BWO. All of this is done in conjunction with our developers at the different EMAG facilities.

Are customers already using the system?

Peter Strohm: EDNA can be operated on both new and existing machines. We already have EDNA running on some existing machines, and customers are ecstatic: The OEE of their production lines have shown significant increases. Based on this information, we are estimating that you will see a return on investment after about a year – if the data that is gathered is used to evaluate and direct action.

How fast is the retrofitting—is production stopped for an extended period of time?

Peter Strohm: Not at all. Most of the work is not performed on-site, but instead at EMAG’s facilities, where we tailor the system configuration to the desired solution. The actual on-site machine retrofit will then only take about a day. Allowing the customer to immediately see the benefits of the desired functionality – and explore the building blocks available within the app. These range from output quantity forecast and up-to-date information on remaining tool life, to detailed breakdowns of the current OEE.

Where and how can we see this data?

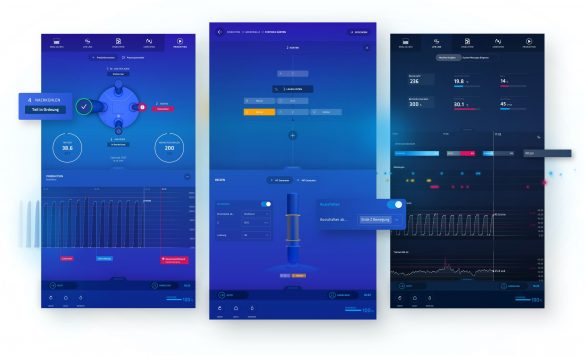

Ricarda Schuhmann: This question brings us to the second thing we focused on during the development phase. It is not enough to just comprehensively network the machine, and process / aggregate / analyze data – the actions that need to result because of this analysis need to be accurately presented and communicated to humans as well. This is exactly what is done with the EDNA LIFELINE DASHBOARDS. In many ways, the style and usability to similar to that of modern day smartphones or tablets. The operators are already familiar with the underlying operating philosophy from using these devices throughout their daily lives, and can therefore learn how to operate the interface very quickly.

Lukas Siegele: And the clear structure pays off: Early warnings are signaled for anomalies, the end of tool lives or machine wear. This prevents overlooked rejects and unplanned downtimes. Production planners, operators and others have access to the dashboard from anywhere—for example on their smartphone.

You’ve now even submitted the entire EDNA ecosystem, which forms the basis of the IoT solutions and the new HMI, for the renowned Red Dot Award—how did that happen?

Peter Strohm: We are very happy with and confident in this solution, and are constantly getting positive feedback. For example, a customer who is already using the system is already looking to retrofit additional machines. So the decision to submit our design and development to the Red Dot Award in the “Design Concept” category was very easy.

How did you rate your chances?

Ricarda Schuhmann: First, it’s important to note that 4,200 companies submitted their latest developments to the Red Dot Award this year. With so much competition, you cannot assume that you are going to win. Which makes us even happier about the end result: After the first round of voting, we were among the 42 “Best of the Best”, and now after the second round of voting, we have even made it to the last round of the “Luminary Award”, as one of only five finalists. This is a huge success and is really validation for our work.

What is next?

Peter Strohm: With EDNA, we offer our customers a comprehensive, future-proof industry 4.0 ecosystem, that is completely modular—which is very important. After all, these is no uniform “right path” for everyone. Each company has to establish its own solutions that meet their requirements. And we are ready for that. Our system is completely open and can transmit data via protocols such as MQTT and REST, or—in the future—also OPC-UA. Connecting additional sensors and integrating products from other machine manufacturers is also no problem. Additionally, our range of available apps is constantly being expanded and the data analysis is thus becoming more and more comprehensive. The approach is future-proof in every respect. We are looking forward to implementing EDNA at an increasing number of customers.