The manufacturing industry faces the challenge of using production space more efficiently while also reducing process times. When machining flange parts, such as differential housings, several separate machining stations are required in conventional production. The VT 200 with counter spindle option shows how modern turning machines can address these challenges through process integration.

Technical concept of the VT 200 with counter spindle

The VT 200 is a vertical turning machine that combines several machining operations in one machine by integrating a counter spindle. The machine concept is based on a two-spindle configuration with lower and upper spindles.

Design and kinematics

The lathe works with a defined flow direction that runs either from right to left or vice versa. The machining processes are organized according to a pairing principle: The right-hand turret takes over machining on the upper spindle, while the left-hand turret operates the lower spindle. If the cycle time is unbalanced, it is also possible for both turrets to machine on the same spindle at the same time. This shortens the overall machining time. This division corresponds functionally to a two-part machining chain within a single machine.

The turrets are designed as HP (High-Performance) turrets and offer the stability and performance required for demanding machining operations. The lathe can also be equipped with Y-axes on one or both sides.

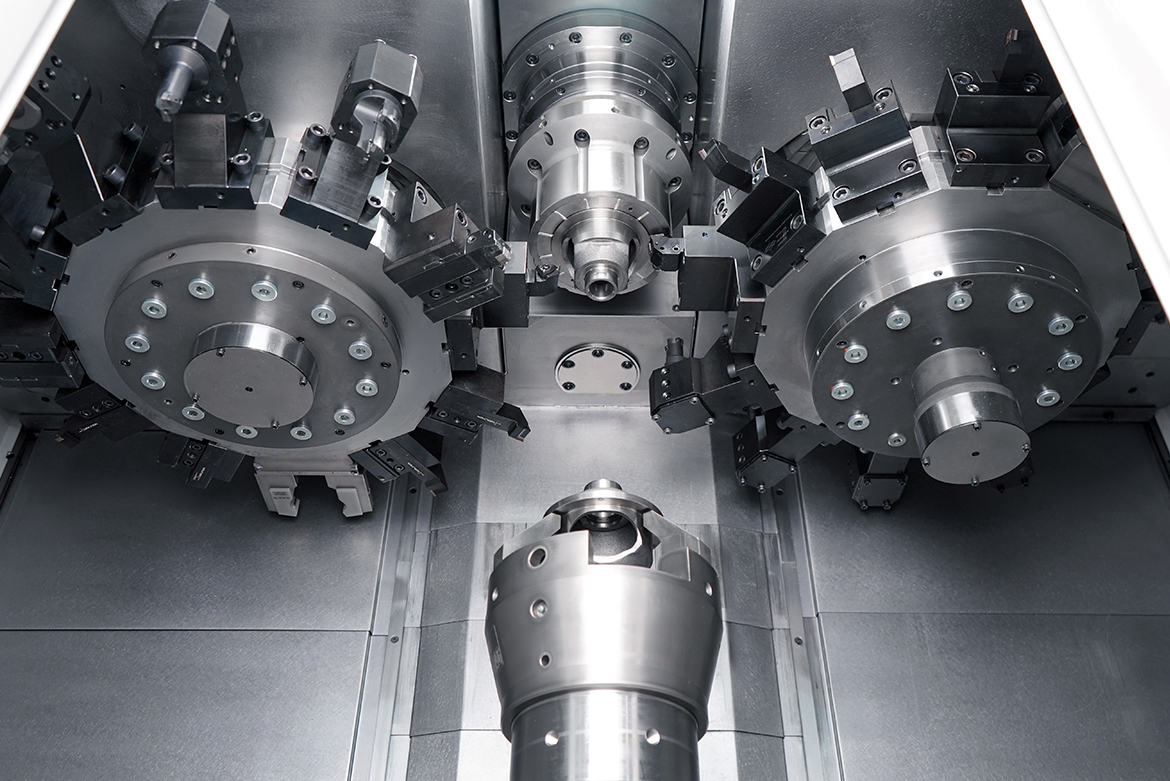

View into the work area of the VT 200: Two opposing turrets enable simultaneous machining on both spindles. The compact design shortens the process sequence.

Process integration: From three stations to one lathe

Conventional machining process

In conventional production lines for differential housings, machining is typically carried out in several separate operations:

- OP10: First turning operation

- OP20: Second turning operation after turning/transfer

- OP30: Finish machining

- OP40: Additional machining steps

This division requires several turning machines and corresponding workpiece transportation between the stations.

The right-hand turret is machining the workpiece in the upper spindle, the left-hand turret is machining the workpiece in the lower spindle. Both work simultaneously and thus enable efficient complete-machining in the VT 200.

Integrated machining in the VT 200

The VT 200 with counter spindle performs the operations OP10, OP20 and OP30 in one lathe. The machining sequence is as follows:

- The workpiece is inserted into the chuck of the lower spindle

- OP10 machining by the left turret on the lower spindle

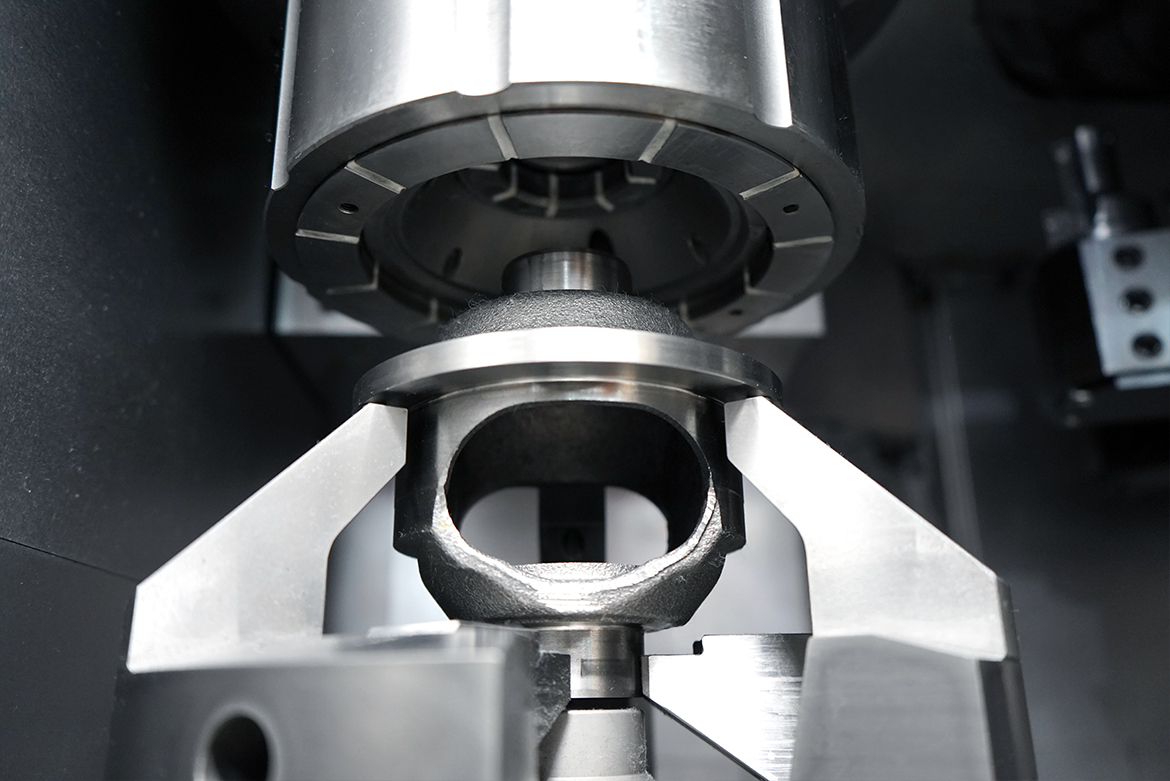

- Workpiece changeover from the lower to the upper spindle (direct transfer)

- OP20 machining by the right-hand turret on the upper spindle

- Finish machining (OP30) in the same setup

- Removal of the finished machining workpiece

The changeover between the spindles is quick and precise, as the two spindles move together and transfer the workpiece directly. This transfer enables complete production without external handling between the machining steps.

Comparison with conventional machining

| Feature | Conventional (3 machines) | VT 200 with counter spindle |

| Number of lathes | 3 (OP10, OP20, OP30) | 1 |

| Installation area | High | Reduced |

| Workpiece transports | 2 external transports | Internal between spindles |

| Clamping operations | 3 | 2 (with internal transfer) |

| Cycle time | Longer due to transports | Shorter due to integration |

Transfer of the workpiece from the lower to the upper spindle.

Technical equipment

The basic equipment of the lathe corresponds to the standards of the VT series. The machine equipment includes

- Two irrespective turrets in HP design

- Two main spindles for simultaneous machining

- Optional: Y-axes for extended machining options on both sides

- Automation interfaces for integration into production lines

Technical data VT 200

| Feature | Value |

| Max. Workpiece dia. | 200 mm |

| Max. Workpiece length | 630 mm |

| Max. Chuck dia. | 250 mm |

| Swing dia. | 270 mm |

| Max. Gripper diameter | 133 mm |

| X-axis travel | 395 mm |

| Z-axis travel | 810 mm |

| Main spindle power (40 % / 100 % ED) | 38 / 29 kW |

| Main spindle torque (40 % / 100 % ED) | 250 / 184 Nm |

| Max. Main spindle speed | 4 500 min-¹ |

| Max. speed of driven tools | 9,600 1/min |

| Driven tool torque 40 %/100 % | 44/33 Nm |

Advantages of integrated machining

- Reduced footprint

The integration of three machining operations in one lathe significantly reduces the footprint of the production line. Instead of three separate machine stations, production only requires one VT 200 with counter spindle. This has a direct impact on capital investments in production space. - Shorter material flow

Internal workpiece handling between the spindles eliminates external transport routes between different lathes. This reduces lead times.

Reduced interface complexity

Fewer machines mean fewer interfaces in the process chain. The coordination between several lathes, including the coordination of cycle times and buffer management, is largely eliminated.

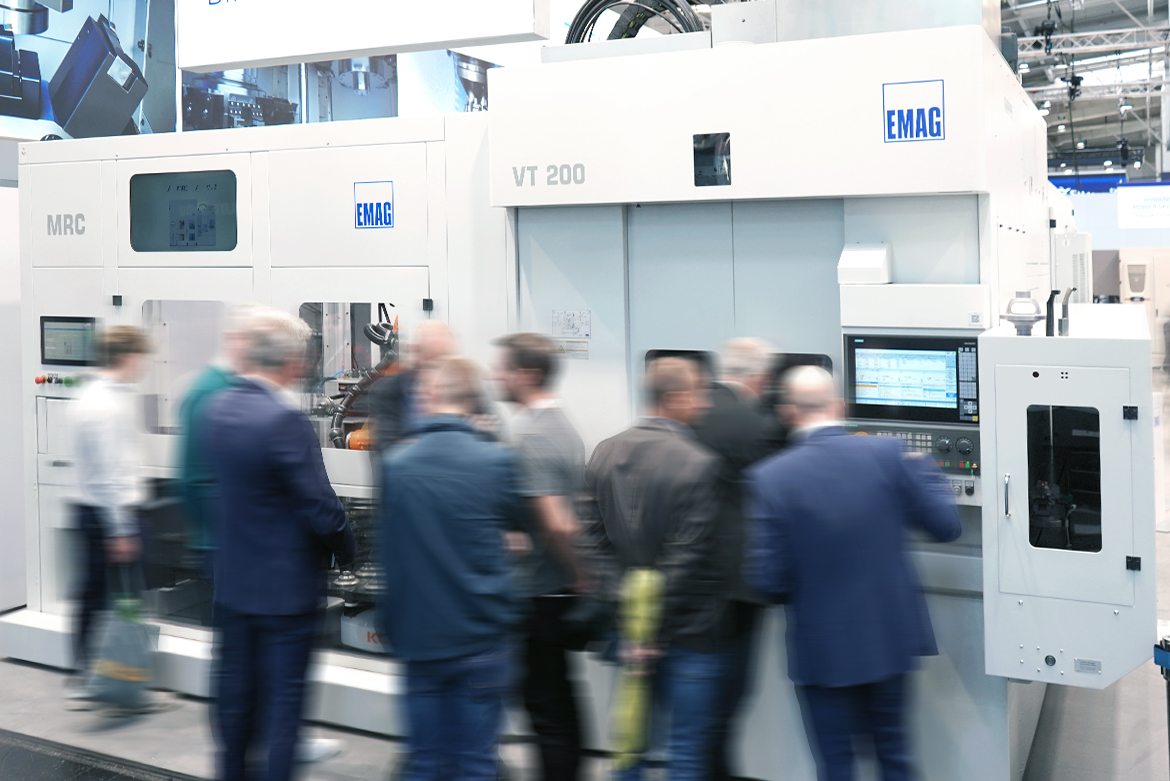

The VT 200 with integrated MRC robot cell at EMO 2025. The combination shows how turning machine and automation merge into a compact, flexible manufacturing solution.

Integration into automated manufacturing systems

The VT 200 with counter spindle is designed for integration into fully automated production lines. Workpieces are handled by robot systems that transfer the components to a shuttle and remove them from a removal position after machining.

Areas of application and range of workpieces

The VT 200 with counter spindle is suitable for machining various flange components:

- Differential housings in the automotive sector

- Transmission components

- Flange parts for drive systems

- Housing parts with complex geometry

The lathe is designed to meet the requirements of medium to large batch production, where process reliability and repeat accuracy are crucial.

More information on the VT series lathes

Author: Konstantin Friedel, Technical Sales, Business Unit Turning, EMAG Maschinenfabrik GmbH