With the introduction of Sinumerik One, EMAG continues its commitment to the latest CNC control technology from Siemens. Replacing the proven 840D sl platform, SINUMERIK One serves as the foundation for the next generation of digitally connected manufacturing systems. Combined with EMAG’s new WinCC Unified-based software, this future-ready control system delivers maximum performance, intuitive operation and seamless integration of smart data applications.

Technical basis: From 840D sl to Sinumerik One

The 19-inch control panel of the Sinumerik One offers a modern, clear user interface. It enables intuitive machine control and simple data input. Ideal for industrial use.

The switch to Sinumerik One is far more than just a hardware upgrade. EMAG is making full use of the new platform – from the powerful NCU to the integrated software architecture:

- New NCU with significantly increased computing power

- IPC BX-39A for improved machine communication

- PLC S7-1500 with TIA Portal programming

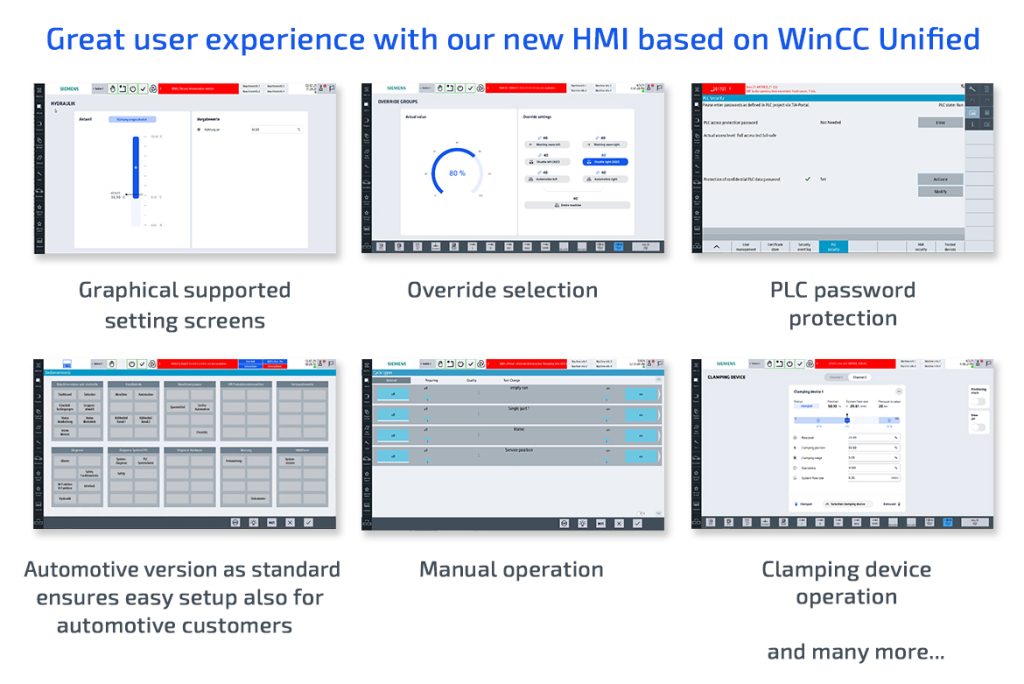

- HMI based on WinCC Unified – successor to the previous “HMI Pro”

- Fully compatible with existing NC programs

As a result, EMAG machines deliver shorter cycle times and greater process stability, while also benefiting from a consistently modern, maintenance-friendly software environment.

Standardized operating concept: New 19″ panel and HT10 handheld control unit

A key feature of the integration of Sinumerik One into EMAG machines is the standardized operating concept.

The new 19-inch operating panel combines clarity with ergonomics. This is complemented by the HT10 handheld control unit, which facilitates manual operation, machine setter and commissioning.

The new Machine Control Panel (MCP1900) with integrated Powerride controller offers LED visualization and dispenses with mechanical stops – a further step towards greater precision and durability in daily operation.

An EMAG VSC machine with Siemens Sinumerik One control panel. The modern control system enables precision processes and simple machine operation.

EMAG software on WinCC Unified

The transition to EMAG software V18 marks the complete transition to the new Siemens ecosystem. WinCC Unified is now used consistently on current EMAG machines, providing a modern graphical user interface, faster parameterization and significantly more intuitive operation.

In addition, the new system is delivered with an automotive version as standard, enabling simple setup for demanding series applications – an important feature for EMAG’s automotive customers in particular.

The new HMI of the Sinumerik One is based on WinCC Unified and offers a clear, graphically supported user interface.

Integration of the EDNA One apps

With Sinumerik One, the EDNA platform is now fully integrated into the Siemens environment.

The EDNA One apps can be called up directly from the Sinumerik One user interface and enable intelligent data evaluation in real time.

The following applications are available:

- EDNA Feature Correction: Correction of process deviations based on data analysis

- EDNA Production Status: Overview of quantities, cycle times and tool changes

More information >>

Another new feature is a revised status bar that displays the workpiece currently being machined in all apps. The system is supplemented by a light and dark mode that adapts operation to different lighting conditions.

Advantages for the user

The combination of Sinumerik One and the EMAG software offers users significant advantages in daily operation:

- Faster data processing thanks to new hardware generation

- Intuitive operation thanks to modern HMI structure

- Future-proof thanks to WinCC Unified

- Increased transparency thanks to integrated EDNA apps

- Compatibility with existing NC programs

With this approach, EMAG is creating the foundation for a future-ready control generation that supports digitalization, process monitoring and sustained efficiency gains.