Wind turbines are a key pillar for the sustainable energy supply of the future – as a relatively reliable source of base load for the electricity grid because the wind blows constantly on the high seas, for example. But how exactly do wind turbines work, why do so-called azimuth gearboxes play an important role and what characterizes their production? We provide some initial answers here.

1. How does the basic principle work?

It is widely known that wind turbines convert the kinetic energy of the wind into electricity: By using the rotors, the air movement is turned into mechanical rotational energy, which can then be converted into electrical energy using a generator. In detail, this means:

- The rotor blades of modern turbines work according to the principle of aerodynamic lift, similar to airplanes: the airflow is guided along both sides of the blade. This creates a faster air movement on the curved upper side than on the straight underside. The resulting negative pressure generates a force on the upper side that sets the rotor in motion.

- The gearbox inside the turbine has the task of significantly increasing the motor speeds of the rotor shaft. In the end, the electricity-generating unit turns 500 to 1,800 times per minute – while the turbine’s rotors only turn 6 to 40 times per minute. Incidentally, modern wind turbines are often equipped with variable transmission systems that allow the transmission ratio to be adjusted depending on the operating conditions.

- There are also gearless concepts. Here, the electricity-generating generator is coupled directly to the hub of the turbine and turns just as slowly as the rotors.

- Overall, as with any form of energy conversion, there are losses. In the case of wind turbines, therefore, no more than 59 percent of the kinetic power of the wind can be used, according to the German Wind Energy Association.

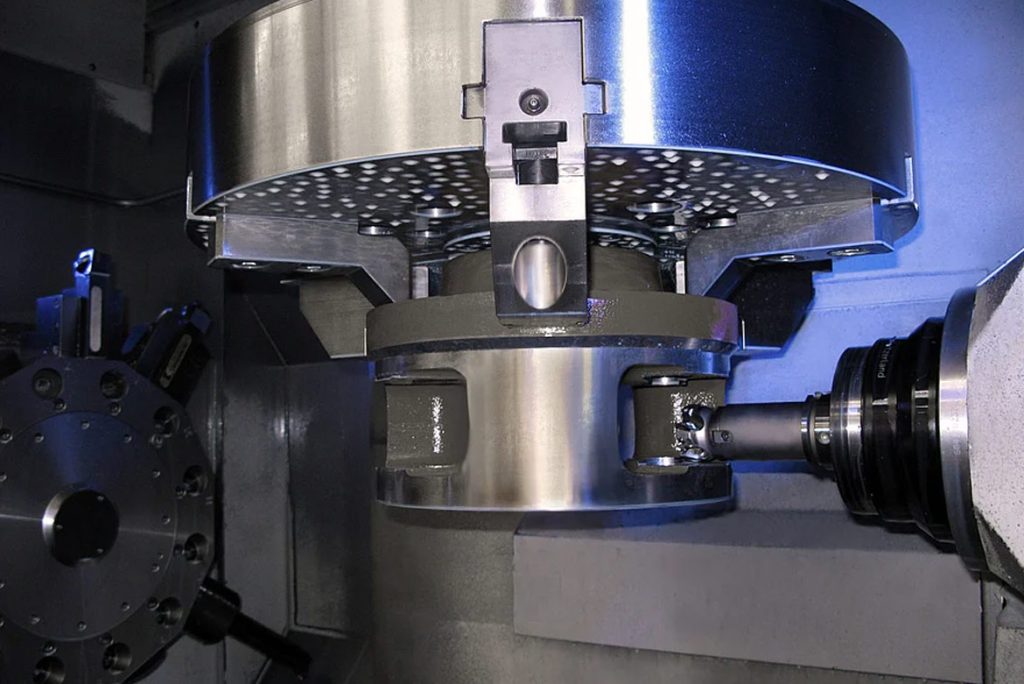

View of the gearbox of a wind turbine.

2. What role do the so-called azimuth drives and gears play?

The question of how wind turbines manage to work particularly efficiently in the first place is particularly interesting – at this point it is worth taking a look at what is known as wind tracking. The basic approach is simple: the alignment of the turbine with its rotor blades must be oriented to the wind so that its kinetic energy can be optimally utilized. Today, active systems with azimuth gears are usually used for this purpose. The word comes from Arabic and originally describes a coordinate used in astronomy to determine the position of a celestial body. In wind power, “azimuth” refers to the entire system for tracking the nacelle – including the azimuth bearing, azimuth drive, azimuth control and azimuth gearbox. Strictly speaking, the latter is a planetary gearbox with three or four stages that are driven by an electric motor. It is not uncommon for several of these drives to be used in order to be able to adjust the large and extremely heavy nacelle along a very large gear ring inside.

3. And how are the rotor blades aligned?

For the wind turbine to operate efficiently in every respect, it is not enough to simply adjust the main alignment of the nacelle – the rotor blades themselves should also ideally align their position with the wind. So-called pitch gears are used for this purpose. They are located at the interfaces between the rotor blade and the rotor head, whereby very small adjustment movements are carried out regularly. This means that the whole thing is subject to very high stresses, which in turn puts the focus on the gearing quality of the components. High material strength and high-precision dimensions are essential.

Transporting a rotor blade: the huge component is adjusted using a pitch gear.

Source: Gerbil, CC BY 3.0 via Wikimedia Commons

4. Who invented it?

Historians are not sure how long windmills have been around. Some historical writings suggest that the first windmills were in operation more than 4,000 years ago. Nevertheless, there is no evidence of windmills in ancient times, for example among the Romans. Persian windmills appear in the 9th century and the technology with a horizontal rotor axis has existed in Flanders, south-east England and Normandy since the end of the 12th century. Interestingly, these are mostly so-called trestle windmills – named after the base frame (“trestle”) on which the mill house is located. This means that the entire mill can be turned by hand so that the wind always comes from the front. From the middle of the 18th century, the first models with so-called wing rosettes appeared, with the help of which the mill aligned itself in the wind.

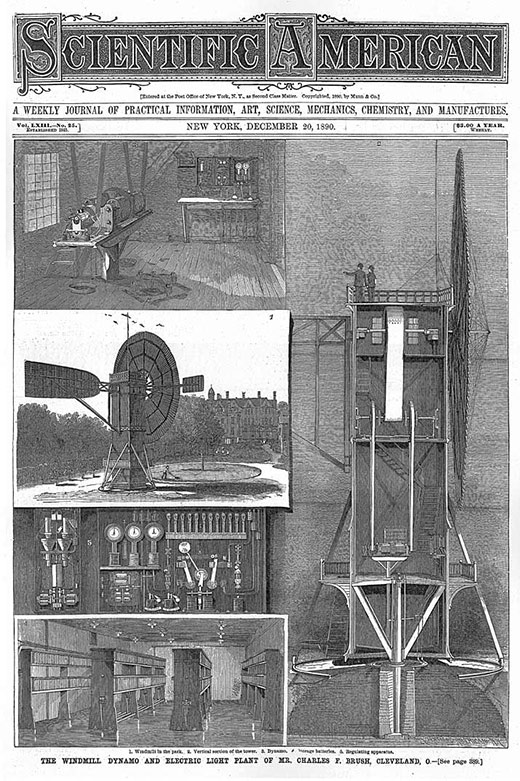

The beginnings: The first plants for generating electricity were built at the end of the 1880s.

Source: By Anonymus - (1890-12-20). "Mr. Brush's Windmill Dynamo". Scientific American 63: p. 54., public domain, https://commons.wikimedia.org/w/index.php?curid=41946

5. What does all this mean for production?

Without gearbox systems, there would be no modern wind turbines – they are indispensable for transmitting the rotor movement to the generator, for aligning the entire turbine using the azimuth system and for adjusting the blades. These systems have to run trouble-free for decades, while the salty air from offshore turbines at sea, for example, attacks their materials. It is important to note that a single azimuth drive weighs around 250 kilograms, which makes repairing or replacing it a costly affair. As a result, manufacturers and the upstream mechanical engineering sector are challenged: The machining quality of housings, planetary carriers and ring gears must meet the highest standards. Technologies such as turning, milling and drilling are used – ideally in multi-functional machines so that handling the very heavy components is as straightforward as possible.

Multi-technology machining of a ring gear: turning, milling and drilling in a single setup