Since its foundation almost 50 years ago, Wandel CNC-Technik GmbH has developed from a classic “garage company” into an established supplier with its own products. Over the years, the second-generation Swabian family business has continued to expand its manufacturing spectrum: from milling to turning and grinding. With the investment in an EMAG WPG 7 angular plunge-cut grinding machine, the grinding capabilities were specifically expanded. In an interview with Gottfried Wandel, we learned detailed insights into the company’s history, the production process and, above all, his experiences with the new grinding machine.

Mr. Wandel, can you give us an overview of the design and development of your company?

Wandel CNC-Technik was founded by my father almost 50 years ago as a traditional garage business. He started out in mechanical engineering as a milled parts manufacturer. At the beginning of the 1990s, we then entered the subcontracting sector. Turning was added in the same decade, and grinding was implemented around 2005 or 2006. Today, we are a medium-sized company with 23 employees here at the site, which I manage together with my sister in the second generation.

The family-owned company Wandel CNC-Technik manufactures up to 20,000 precision parts per month at its site. In the picture: Gottfried Wandel, Managing Director of Wandel CNC-Technik GmbH.

What is the breakdown of your employees?

Of our 23 employees, three work in administration and the rest in production.

You mentioned the technological development from milling to turning and grinding. How did the turning process come about?

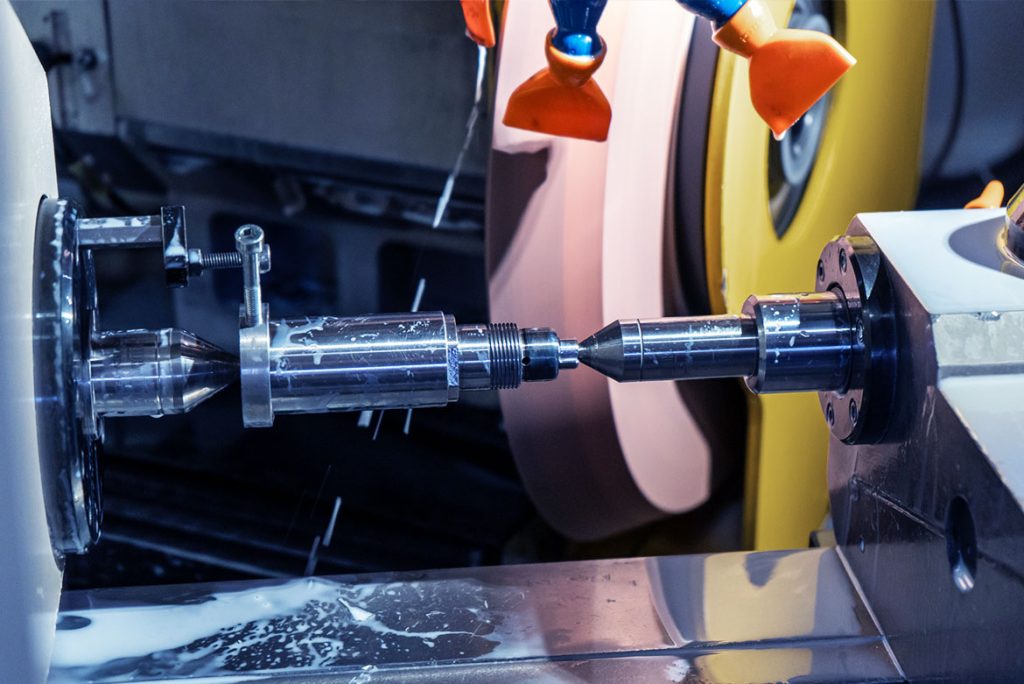

We actually come from milling. A large customer project then brought turning into the company, which we then taught ourselves with a lathe operator that we hired . We are now also active in turn-milling. Since last year, we have also implemented hard turning.

How did grinding become another process in your portfolio?

Grinding, which was also requested by a customer, was initially purchased as a service. At some point, the service provider’s turnover became so high that we decided it would be better if we could do it ourselves. So, we started with a grinding machine and gradually added various grinding operations. First external cylindrical grinding, then internal grinding, then angled plunge grinding. Both pre-grinding in a soft state and grinding in a hard state went hand in hand for us.

How many components do you produce each month in your company?

The number of components we produce here at the company is between 15,000 and 20,000 per month. That includes all processes: Turning, milling and grinding.

And how high is the proportion of components that have to be ground?

Just under half of all components are ground. However, some of the workpieces, especially those that have to be gear cut, are ground externally.

What criteria do you use to decide which components you grind yourself and which you send out for grinding?

That mainly depends on technologies that we don’t have in-house, such as gear cutting. If tooth profiles need to be ground or gears need to be positioned for bearing seats, then we send the components outside.

Can you give us an insight into your variety of parts?

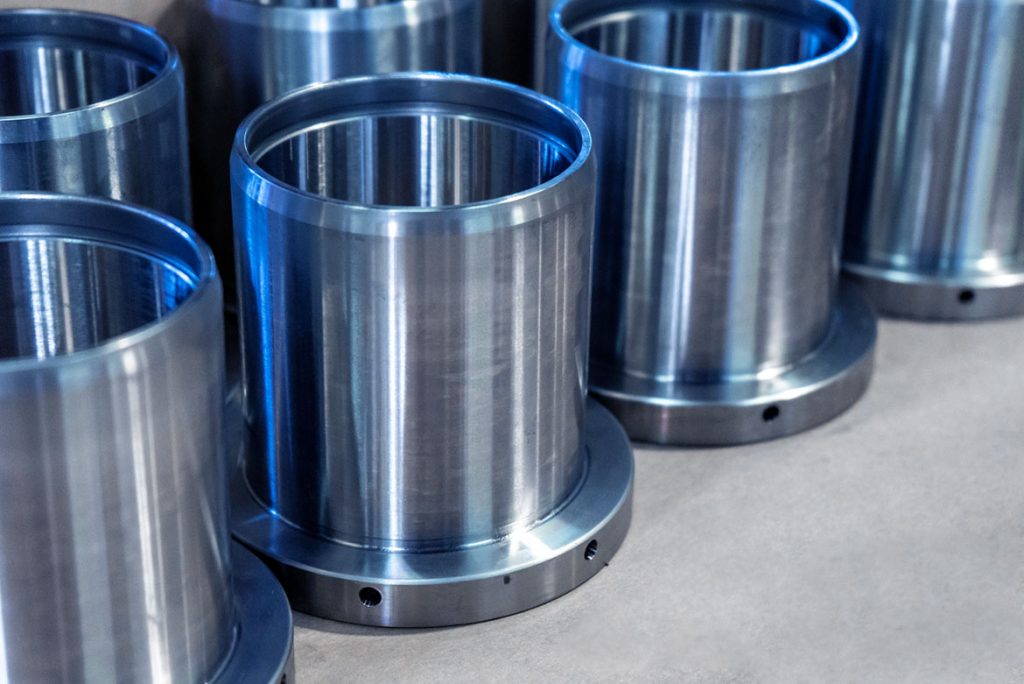

We machine a lot of forged blanks in the turning area, manufacture drive shafts, intermediate flanges for the commercial vehicle industry, but also classic machine components in the turning area such as worm shafts or other drawing parts according to customer requirements. In milling, the focus is mainly on gearbox housings, also in aluminium or cast iron, cast steel, cast iron. In grinding, we work with symmetrical or round components with diameters ranging from 10 to 150 mm and lengths of up to 1000 mm. We also have our own product, the ball screw nut, with which we cover the common sizes between 16 and 50 mm.

In which applications are your ball screws used?

Ball screws are mainly used in handling technology or for adjusting platforms – wherever components need to be moved, but also in mechanical engineering.

You currently have four grinding machines in use. How does the WPG 7 fit into your existing machine concept?

The WPG 7 was added as a supplementary grinding machine for us. It was mainly purchased for our ball screw nuts, as we have a lot of flange nuts that require angular plunge-cut grinding as a technology. The WPG 7 was predestined for this.

The heat-stable WPG 7 requires little floor space and optimally complements the larger grinding machines in the machine park.

The good accessibility of the WPG 7 enables efficient retooling for batches between 20 and 200 pieces.

What batches do you machine with the WPG 7?

We run batches of between 20 and 200 pieces. The machine is really well suited to these batches and also to the size of the components.

How often do you have to retool the machine?

We retool the WPG 7 at least once a day, or twice a day if the workload is high. Easy accessibility and compactness of the machine are very helpful here.

What prompted you to purchase a machine that specializes in angular plunge-cut grinding instead of a universal machine that allows you to switch between straight and angular plunge-cut grinding?

We already had a straight plunge grinding machine in-house for long and larger components and were looking for an alternative. In other words, we wanted bevel stitch and compact. The alternative would have been angled plunge-cut and large, which would have brought with it the problem of long travel distances. The space available here on site is also limited. That’s why we opted for small and compact as an addition to our existing straight plunge grinding machine.

How has the WPG 7 influenced your production process?

Previously, with the Karstens K 41, we had a relatively large machine with a center distance of one meter, although our components tend to be in the small range – up to around 100 mm in diameter and 50 mm in length. This means that we have always used a relatively large machine to grind small components. At some point this became a thorn in our side and we said we needed something smaller, something more manageable. The WPG 7, with its compact design, takes up relatively little space, which has already improved our processes. It is also very dimensionally stable – the compact design also means that the heat transfer is very low. The travel paths of the WPG 7 are much shorter and the movements faster than with the old machine.

The compact work area of the WPG 7 enables precision angular plunge-cut grinding.

Your employees have emphasized the thermal stability of the machine. Can you say more about this?

The thermal stability of the machine means that it is not so difficult to start up the machine and use it over a longer period of time. We have little to no heat build-up in the machine, which we are not used to from our other machines. With the WPG 7, you switch it on and it just works.

For which specific components does the WPG 7 offer particularly significant advantages?

As we were previously unable to perform angular plunge grinding, it was always difficult when we had to grind flanges for squareness or axial run-outs. This was never ideal, also in terms of the sanding pattern. With the angled plunge-cut grinding option of the WPG 7, this is now much better. We were able to achieve enormous advantages here: faster running times and higher quality.

The sleeves benefit in particular from the angular plunge-cut technology of the WPG 7, which achieves better surface finishes.

How does the control of the WPG 7 differ from your other machines?

As we have a 35-year-old grinding machine in-house with a correspondingly old control system, the control technology for the new machine was very important. The user-friendliness of the WPG 7 control system is a big plus. Of course, we and our employees first had to learn how to use it.

How is the programming process organized?

We program everything directly on the machine. It is therefore important that programming is user-friendly. The programs are then saved on the machine and called up again when required.

How many different components do you machine on the WPG 7?

There are many similar components, but they differ in diameter and size. In total, there are probably about 50 different components running through the machine.

How would you describe the cooperation with EMAG during the procurement and implementation of the WPG 7?

The commissioning and support from EMAG were very good. We came to the company with our requirements and were introduced to the WPG 7 in the factory. We were able to have components ground and test sample components and sample batches on site. The support was really good and we are completely satisfied with the process right through to commissioning.

How would you rate EMAG’s service after commissioning?

The service is excellent. We can always reach someone on the phone, which I really appreciate. It’s good that you don’t have to fiddle around with ticket numbers, but that someone deals with the matter personally. I can only report positive things.

Were there any training courses for your employees on the new machine?

Our employees were thoroughly trained on site by EMAG training managers. We set up and programmed our components on the machine – the overall training experience was very good.

How did the commissioning of the machine go?

The machine was delivered, unloaded with the forklift and set up – virtually ‘plug and play’ within a day. The machine was then up and running.