In the heart of the Eifel region, around 50 kilometers from Koblenz, Bharat Forge Daun mechanical production works at the highest level, producing extremely precise, rotationally symmetrical series components, among other things. This means that challenges like difficult surfaces and positional arrangements are common. Several EMAG machines are currently being used in the production of a stator housing for electromobility – with a focus on process reliability. In the following interview, Christoph Steffens, Head of Mechanical Production at Bharat Forge Daun, explains the reasons for using EMAG machines and why EMAG service is so important.

Success Story

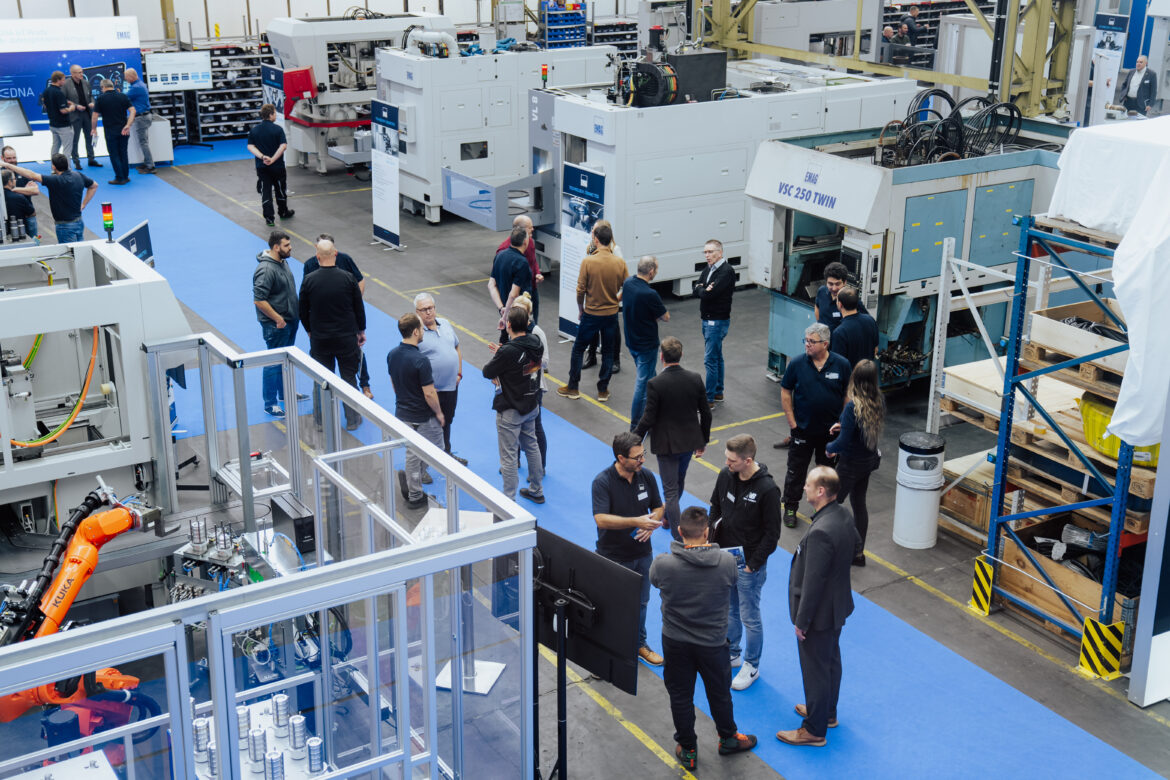

During the Open House Retrofit at the Eislingen plant, EMAG presented the future of industrial machine modernization. Visitors had the opportunity to experience the latest technologies and retrofit solutions at first hand.

The monthly number of new registrations of e-cars in Europe is currently increasing – and with it the required quantities for the e-drive components. The example of the supplier Linamar Technology Hungary shows how the production task behind this can be solved effectively. The e-drive specialists have recently invested in EMAG machines for the production of shafts and gears. A conversation with István Bíró, Project leader at Linamar Technology Hungary, about the new solution at the site in Békécsaba.

With around 15 percent growth per year, the Czech supplier ZLKL has an impressive success story. Advanced production technologies with automation components play a decisive role in this. For example, around 25 EMAG machines are in operation at ZLKL’s Czech sites. Karel Zeman, Senior Manager Machining at ZLKL, discusses his company’s formula for success.

EMAG L.L.C. is excited to announce that Mark Comeaux, Regional Sales Manager responsible for IN, OH, KY, TN and WV has been awarded our 2020 Sales Excellence Award.

Although 2020 was difficult for many manufacturers, Mark used his determination, drive and commitment to EMAG and his customers to secure $12.6 million in new sales. The machines sold touch on all technologies available within the EMAG Group and included equipment to manufacture transmission shafts, end machining, rough and finish turning on a 3-turret lathe complete, induction hardening of automotive steering pinions and ECM technology for high purity valves and medical components. Some projects include:

- Three turnkey cells utilizing our VTC 250 DUO ED machines including gantry robot, post process gages with feedback to machine and automatic mastering.

- Three turret self-loading vertical shaft lathes that process shafts for a transmission company, used for facing and centering the shaft, rough and finish turning – all performed in one, compact machine.

- Induction hardening machine used for the processing of steering pinions.

- Multiple electrochemical machines used to produce high purity valves and a variety of medical components.

- Two VT 4-4 hard turning machines for shafts used in the production of hydrostatic and orbital motors.

- A VM 9 VTL with full turnkey capabilities, including gantry and automatic conveyor infeed system. Processes include turning and burnishing.

- Automation re-tool of current EMAG machines originally installed in 1999 – this is a transform automation system that moves parts from OP to OP, flips them over, and includes a blow off device for rotating clutch.

Although his sales numbers are extraordinary, his commitment to customer relationships and willingness to help teammates are what really won this distinction.

Mark is no stranger to sales achievements, he’s been with EMAG since July of 2016, and has received four annual top sales awards. We’re very lucky to have him, and appreciate all his contributions to EMAG and the sales team, and his commitment to his customers. Congratulations Mark, from all of us at EMAG!

For over 50 years, Kordel has developed a variety of drive systems and transmissions used in agricultural and construction equipment, as well as industrial trucks. This is a task that requires both robust machining and precision, simultaneously. The family-owned business with its headquarters in Dülmen near Münster, Germany relies on the competence of its employees, flat hierarchies and a high level of integration with a “state-of-the-art” machine system. For over 20 years, EMAG’s pick-up technology has played a major role at Kordel. More than 17 production solutions from the Southern German machine builders are used at the production sites in both Germany and Poland. The most recent additions are two VLC 200 GT turn-grind centers. Below is a conversation we had with the Kordel Managing Director, Johannes Kordel, about the success of his company, and the important part mechanical engineering has played in it.

For over 30 years, Bäringhaus & Hunger, based in Grünhainichen near Chemnitz, have been active in the part manufacturing industry – experiencing growing success with the production of high-precision turned and milled parts. About 90 percent of orders received at Bäringhaus & Hunger come directly from suppliers in the automotive industry. From almost the very beginning, EMAG has played an important role in this as a mechanical engineering partner, and currently have over 20 machines on the Bäringhaus & Hunger shop floor. How did this partnership develop and why is it still so important today? We spoke with partners, Matthias and Sebastian Hunger, the second generation of the family to run the company, about the secret to their company’s success.

Interprecise Donath GmbH, based near Fürth, Germany, develops and produces rolling bearings that are used in a variety of machines and gears – an extremely precise task that involves just a few micrometers and requires special surface qualities. For about three years, VL vertical lathes from EMAG have been used for this machining, achieving lower unit costs in the soft and hard machining of many components. We sat down for a conversation with Interprecise Managing Director, Christian Witte, about the market challenges and advantages of pick-up technology.

With the introduction of EDNA, EMAG has developed a complete ecosystem for digitizing industrial production. This required strengthening bonds between teams across company boarders – in addition to the EMAG subsidiaries, diverse external digitization specialists were involved. For this reason, we knew that we had to invite several different people to join this conversation: Peter Strohm, Business Development Manager IoT at EMAG, as well as Ricarda Schuhmann and Lukas Siegele from our partner intuit to tell us about the development process, the possibilities offered by EDNA and why they are so happy about receiving this very special award.

As the year comes to a close, we’d like to review some of the most exciting events from the past year such as the EMAG Technology Forum and EMO Hannover.