EMAG L.L.C. is excited to announce that Mark Comeaux, Regional Sales Manager responsible for IN, OH, KY, TN and WV has been awarded our 2020 Sales Excellence Award.

Although 2020 was difficult for many manufacturers, Mark used his determination, drive and commitment to EMAG and his customers to secure $12.6 million in new sales. The machines sold touch on all technologies available within the EMAG Group and included equipment to manufacture transmission shafts, end machining, rough and finish turning on a 3-turret lathe complete, induction hardening of automotive steering pinions and ECM technology for high purity valves and medical components. Some projects include:

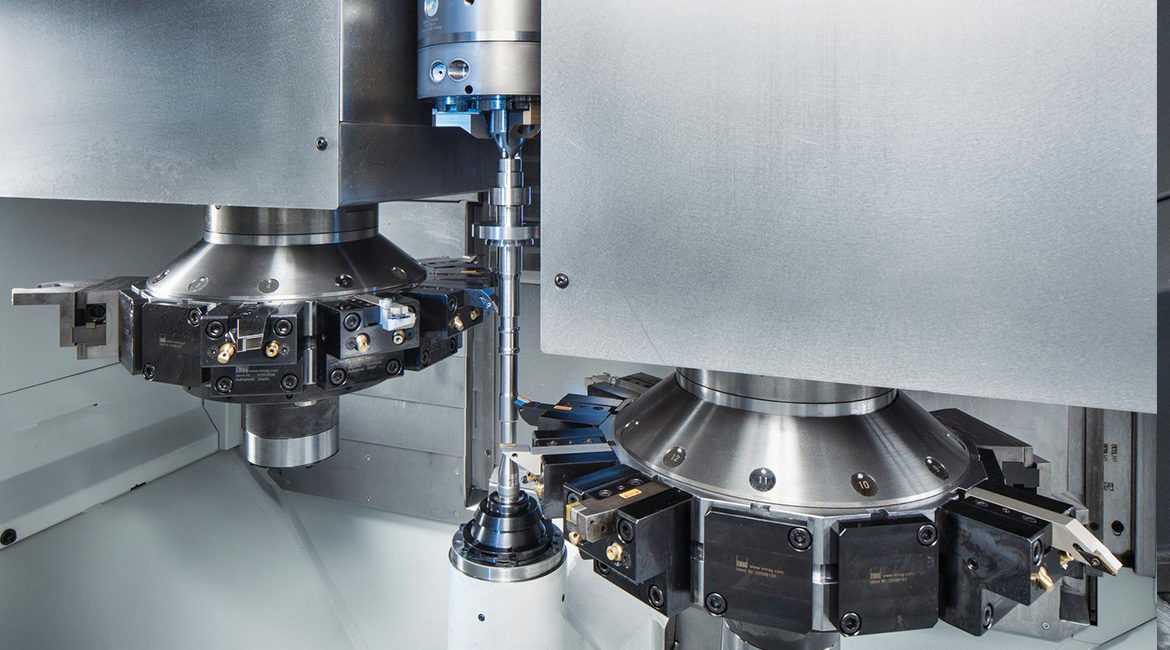

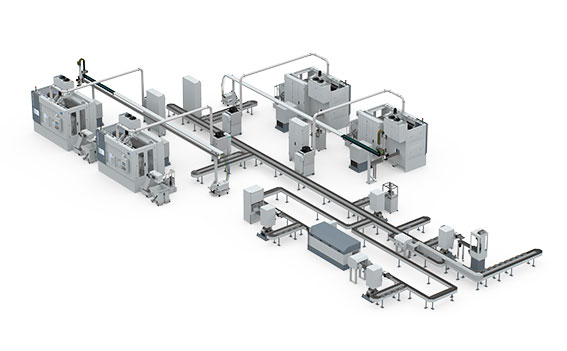

- Three turnkey cells utilizing our VTC 250 DUO ED machines including gantry robot, post process gages with feedback to machine and automatic mastering.

- Three turret self-loading vertical shaft lathes that process shafts for a transmission company, used for facing and centering the shaft, rough and finish turning – all performed in one, compact machine.

- Induction hardening machine used for the processing of steering pinions.

- Multiple electrochemical machines used to produce high purity valves and a variety of medical components.

- Two VT 4-4 hard turning machines for shafts used in the production of hydrostatic and orbital motors.

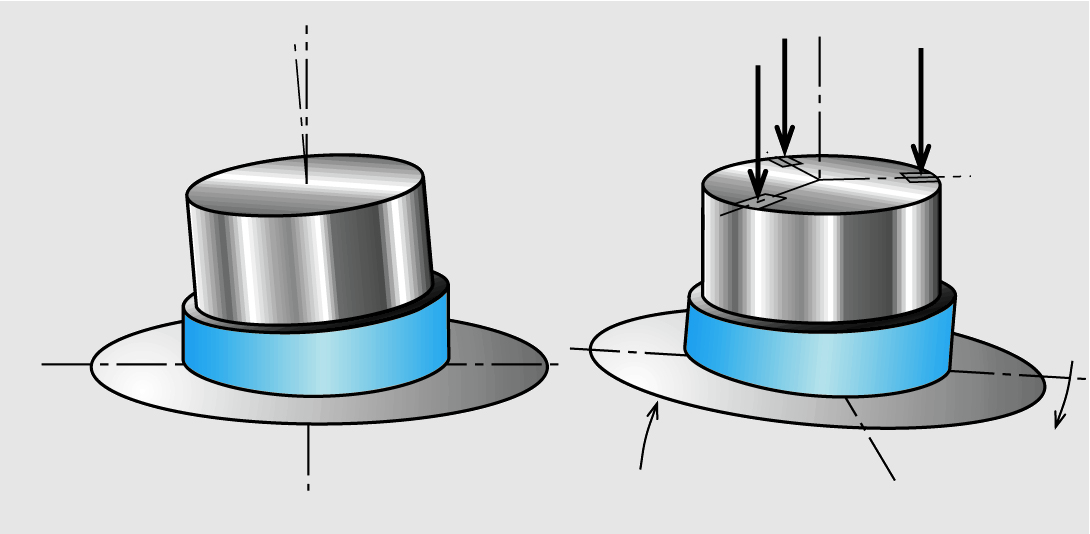

- A VM 9 VTL with full turnkey capabilities, including gantry and automatic conveyor infeed system. Processes include turning and burnishing.

- Automation re-tool of current EMAG machines originally installed in 1999 – this is a transform automation system that moves parts from OP to OP, flips them over, and includes a blow off device for rotating clutch.

Although his sales numbers are extraordinary, his commitment to customer relationships and willingness to help teammates are what really won this distinction.

Mark is no stranger to sales achievements, he’s been with EMAG since July of 2016, and has received four annual top sales awards. We’re very lucky to have him, and appreciate all his contributions to EMAG and the sales team, and his commitment to his customers. Congratulations Mark, from all of us at EMAG!