The automated production of turned parts in medium and large batch production requires CNC turning machines that combine productivity, process reliability and cost-effectiveness. The MSC 5 DUO from EMAG’s Classic series addresses these requirements with a machine configuration consistently designed for automation. As a fully automated CNC lathe with a double-spindle concept, the machine is positioned in the compact manufacturing cell segment for workpieces up to 120 mm in diameter and 85 mm in length.

Machine and automation concept

The MSC 5 DUO is based on a continuous material flow concept in which workpiece handling is fully integrated into the production process. The machine has two processing stations, each with its own spindle unit, designed as a first and second setup. The material flow takes place from left to right: the raw-parts are removed from a stacker storage unit, machined and deposited in a separate storage unit on the right-hand side of the machine after completion. The handling system uses a gantry with twin-gripper technology, which enables raw and finished parts to be picked up simultaneously. This approach minimizes non-productive times. The cycle time for a complete workpiece cycle is 41 seconds in the standard configuration. This time can be reduced to 21 seconds with the optional addition of a second carriage on the gantry, which significantly increases throughput capacity.

The compact MSC 5 DUO manufacturing cell with integrated gantry handling and twin-gripper system. Two lateral storage units for raw and finished parts and FANUC control for fully automated operation.

Workpiece handling and turning technology

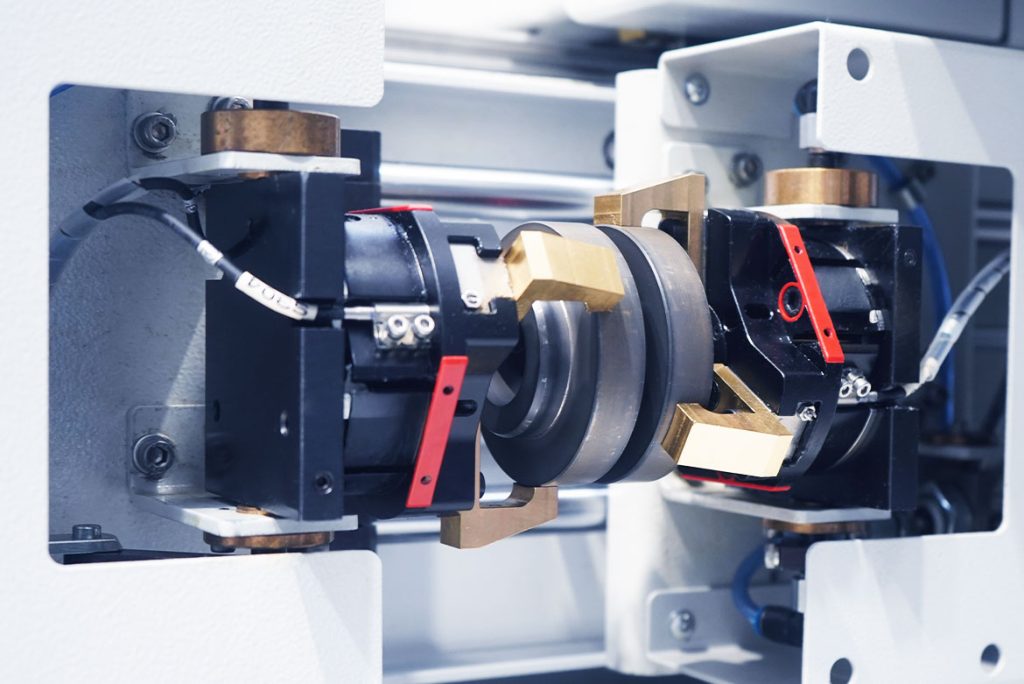

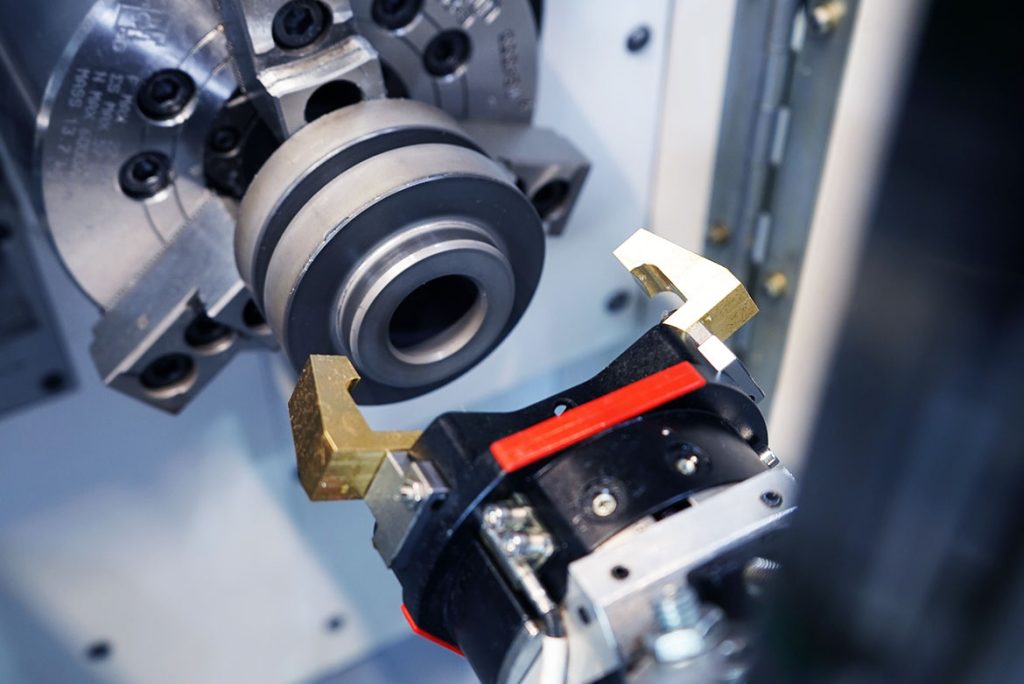

A key feature of this CNC lathe is the integrated turning function in the handling system. After machining in the first setup (OP 10), the workpiece is picked up by the twin-gripper and placed in a changeover station. There, the clamping position is changed from OP 10 to OP 20. The twin-gripper then places the workpiece in the second setup (OP 20). This solution enables complete machining in two setups without manual intervention or additional turning devices.

The changing station enables a fully automatic clamping layer change. The twin-gripper sets down the workpiece, the clamping position is changed and the transfer to OP 20 takes place.

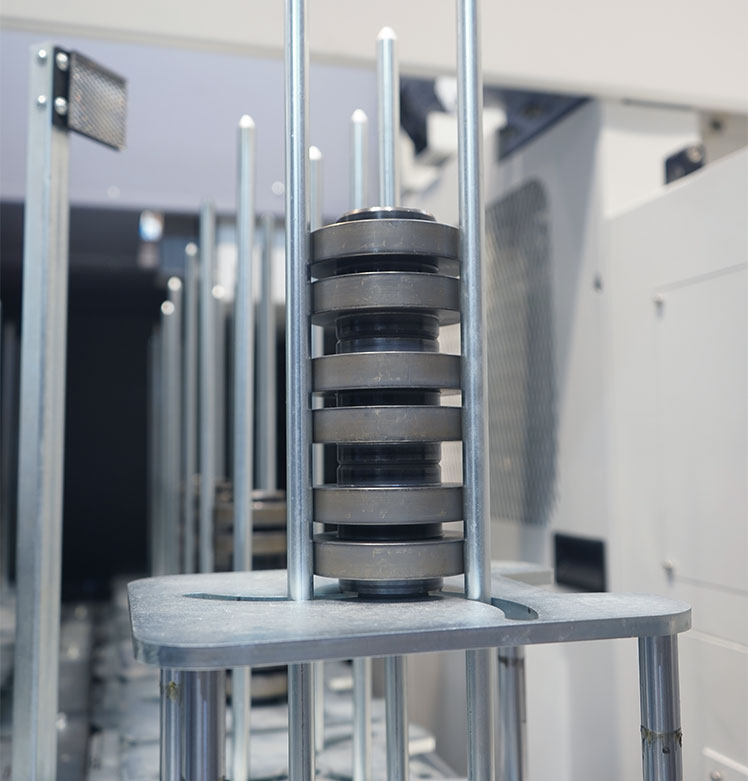

The stacker storage unit used has lift-out stations where the workpieces are positioned for pick-up or release by the gantry. For applications that require loading and unloading on the same side of the machine, the storage system can be equipped with a second lift-out station. This flexibility extends the machine’s range of applications in different production layouts.

The stacker storage unit with vertical workpiece arrangement and lift-out station for gantry removal. Two lift-out stations are optionally available to realize loading and unloading on the same machine side.

Control and drive technology

The MSC 5 DUO is equipped with the FANUC 0i TF-Plus control system, which is also used in the sister models HSC and USC of the Classic series. This control platform provides a uniform user interface across the range and simplifies operation and programming for users working with different machine types. The main spindles are driven by FANUC motors, which provide 5.5 kW of power in continuous operation. A more powerful 7.5 kW spindle version is available for applications with increased power requirements. The CNC lathe can optionally be equipped with a linear measuring system in the X-axis. This equipment increases the positioning accuracy and compensates for thermal influences and mechanical deviations in the feed axis, positively affecting the machining quality.

Machining range and machine specifications

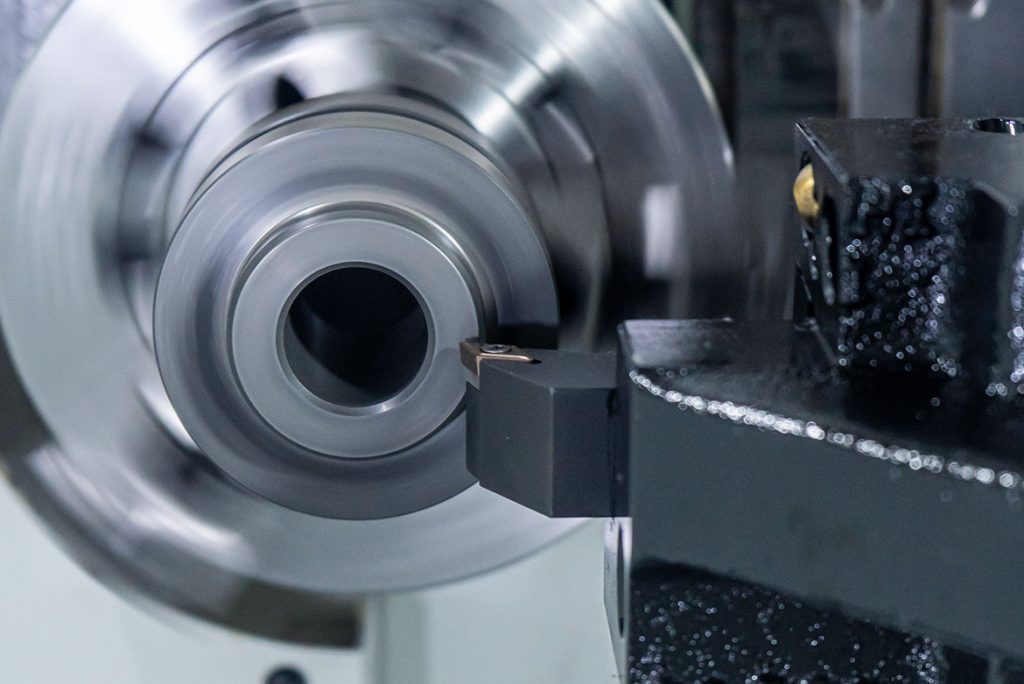

The capacity of the MSC 5 DUO is designed for workpieces with a maximum diameter of 120 mm and a maximum length of 85 mm. This dimensioning corresponds to a common standard in the compact CNC turning machine segment and covers a wide range of turned parts in the automotive, hydraulic and general mechanical engineering industries. The machine design follows the concept of the Classic series, which relies on proven machine components and a robust construction. The integration of machining stations and automation in a compact machine housing reduces the space requirement and enables installation in existing production halls without extensive structural modifications. The VL 3 DUO from EMAG as a larger machine model offers significantly higher spindle capacities and larger working capacities, but is aimed at applications with correspondingly dimensioned workpieces.

Machining of a turned part in the MSC 5 DUO.

Areas of application and application profiles

The CNC lathe MSC 5 DUO is particularly suitable for production tasks where complete machining of turned parts in two setups is required. Typical applications are found in the production of gears, bushes, fittings and flanges. The fully automated design with material storage enables operation with reduced staffing or in unattended operation during off-peak times. The cycle time of 41 or 21 seconds allows a high workpiece throughput, which predestines the machine for medium to large batches. Companies that already work with FANUC controls benefit from the standardized control platform, which enables quick training of the operating personnel and increases the availability of spare parts and know-how in the company.

The twin-gripper of the portal handling system inserts a workpiece with precision into the chuck of the machining spindle. Fully automated loading takes place without manual intervention during the process.

Process reliability and production integration

The automation of the MSC 5 DUO reduces manual intervention in the production process and thus minimizes potential sources of error. The defined workpiece guidance from the raw part storage to the finished part storage ensures reproducible process execution. The twin-gripper system with integrated turning function eliminates additional handling stations and reduces the number of workpiece fixtures required. The FANUC control system offers appropriate interfaces for integration into higher-level manufacturing systems or MES environments. The recording of machine data, processing times and quantities enables connection to modern production planning and monitoring systems.