Double helical gears are a special type of gear in which two helical gears are arranged in a mirror image configuration on the same shaft. This design can withstand high loads and is significantly more cost-effective to manufacture than herringbone tooth profiles. Double helical gearing combines the advantages of helical gearing, which can absorb high loads, with the additional benefit of compensating for axial forces through its mirror-image arrangement.

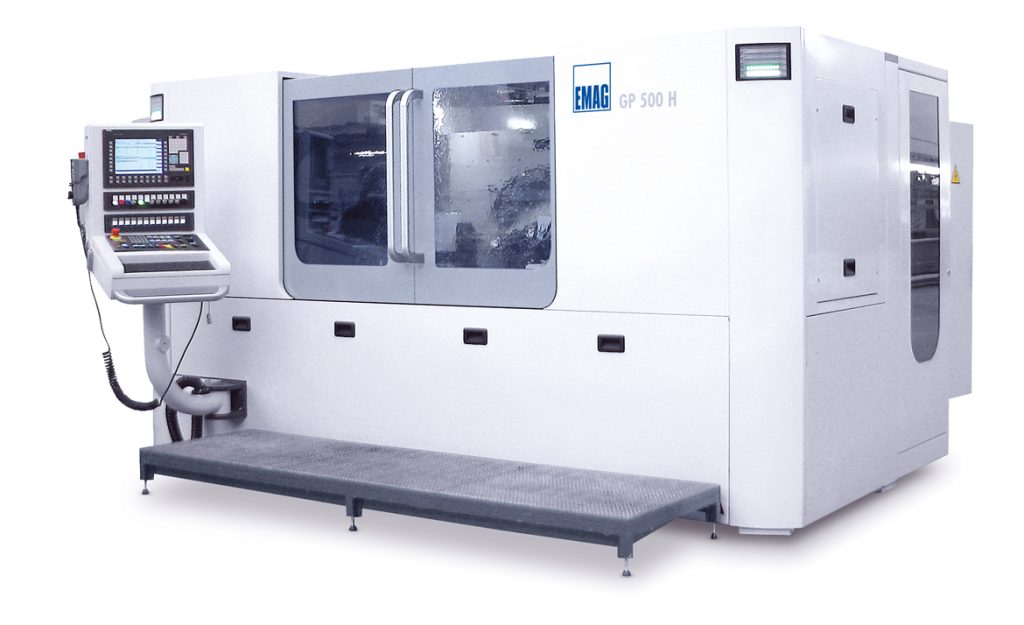

The production of double helical gears requires complex and highly flexible machine tools, Since interfering contours make the use of large grinding wheels impractical. With the GP 500 H profile grinding machine, EMAG SU provides the ideal soution. It allows the use of grinding wheels in various sizes for both internal and external grinding, while short changeover times make isparticularly well-suited to the aerospace industry.

As drive systems in traditional gear manufacturing also continue to increase cable density – leading to more complex components – the GP 500 H proves to be an equally effective choice in this field. The GP 500 H offers not only advanced grinding technology but also high overall efficiency. Fast changeovers and the ability to check workpieces directly on the machine using a swivel-out measuring probe significantly reduce costs – often more than the sanding operation itself – especially in small-batch production.

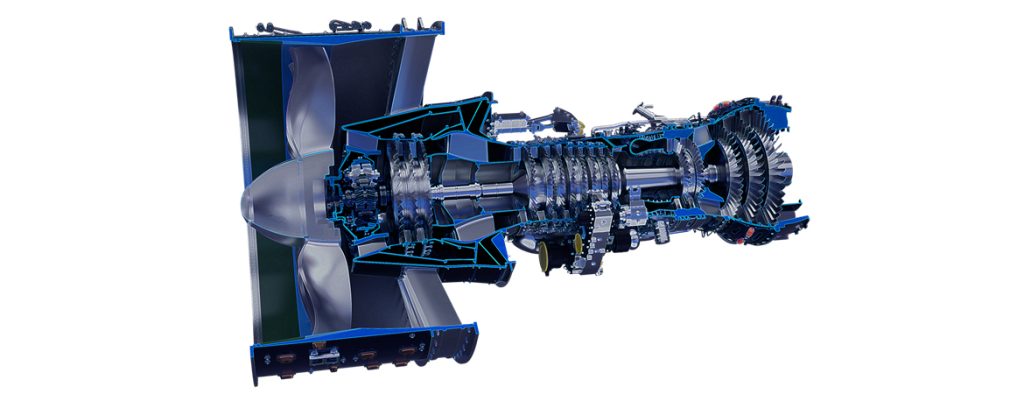

Double helical gearing completely eliminates axial forces during power transmission. This enables a compact design with high power density and is used particularly in turbofan and helicopter gearboxes. The GP 500 H from EMAG machines these complex tooth profiles with precision.

Compact power density

Double helical gearing delivers exceptionally high power density in a compact design. By combining both tooth profiles, the effective tooth width increases, enabling the transmission of considerable torque while maintaining compact dimensions. This makes the design particularly suitable for planetary gears in aerospace applications, where weight and space optimization are critical.

The ability to transmit high torques in such a compact form is achieved through the distribution of loads across a greater number of teeth and the efficient use of the available installation space.

The double helical gearing transmits the torque between the fan and the low-pressure turbine without axial forces. It is crucial for the compact design of turbofan engines and meets the highest precision requirements. Their production requires specialized grinding technologies.

Turbofan engines

Double helical gearing is primarily used in turbofan engines, especially in the gears connecting the low-pressure turbine to the fan. Because of the critical demands on reliability and tooth profile precision in this position, any failure could have catastrophic consequences. In modern turbofan engines, these tooth profiles are part of complex planetary gearboxes. Operating at high rotational speeds and under extreme conditions, they require the highest levels of production precision and rigorous quality assurance measures.

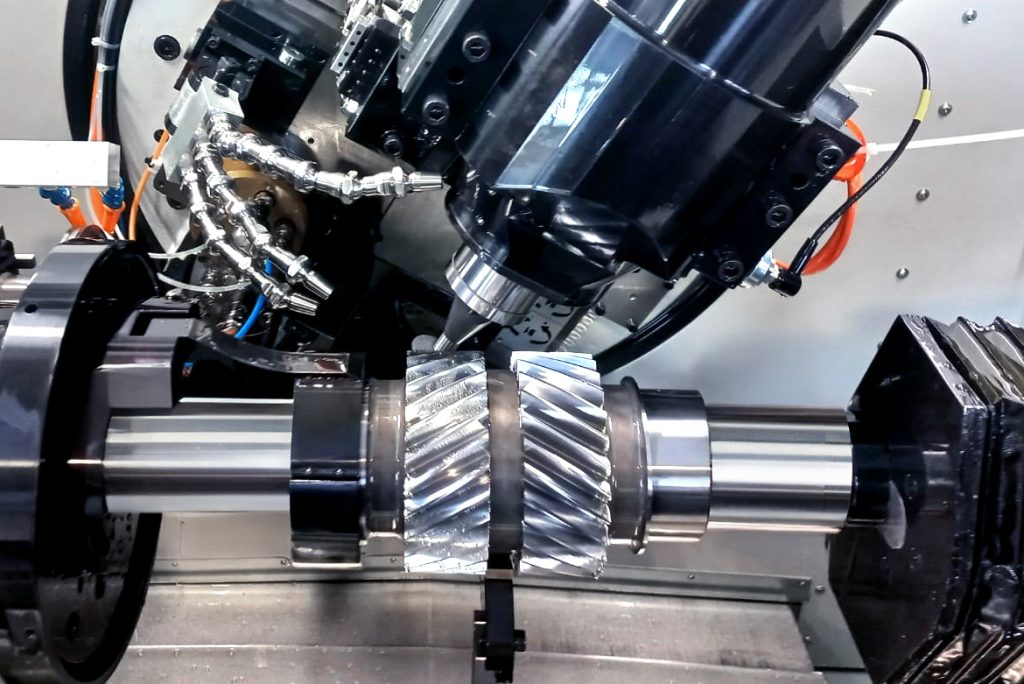

The GP 500 H machines double helical gears for turbofan transmissions with the highest precision. The 5-axis kinematics, i.e. a profile grinding machine with tangential axis, enables the exact grinding of complex geometries with very small grinding wheels. Ideal for aerospace applications with the highest demands on quality and reliability.

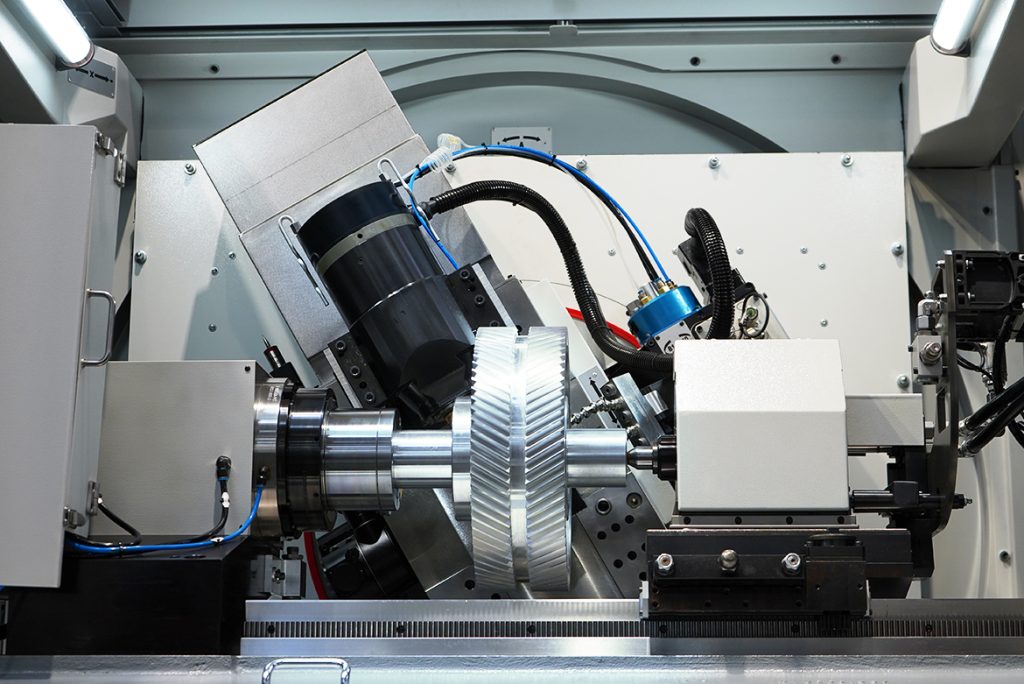

Helicopter gearboxes

In addition to turbofan engines, double helical gears are also used in the main gearboxes of helicopters. The requirements are similar to those for turbofan engines, although the number of teeth is often significantly higher: high torque, a compact design and absolute reliability are essential for safe operation.

Work area of the GP 500 H 5-axis grinding machine for machining double helical gears. Specially developed for complex helicopter gearboxes with the highest reliability requirements. Compact design enables high torque transmission with minimum installation space.

GP 500 H for grinding double helical gears

The GP 500 H is a profile grinding machine with a tangential axis (5 axes), specially developed for the complex requirements of grinding double helical gears.Because of the interfering contour of the mating gear (small run-out of the grinding wheel between the tooth profiles), only very small grinding wheels can be used. This makes profile grinding the only economical solution for this task. To prevent collisions between the grinding head and the workpiece, the grinding wheel is setup on a mandrel and positioned in the center of the grinding area. The grinding arbor is supported by a counter bearing, ensuring perfect concentricity and low-vibration grinding.

After hardening, double helical gears often show distortions that must be corrected on the profile grinding machine. The intersection point of the two helical gears (arpex point) must be produced with high precision and the flanks must be ground cleanly with an even hardening layer on both gears. This places extreme demands on the centering, i.e. the positioning of the grinding wheel relative to the workpiece. To achieve this, EMAG has developed advanced software: Using a measuring probe,the machine checks both tooth profiles before grinding to determine the optimal wheel position. This pre-check reveals whether the workpiece can be ground cleanly or whether hardening distortion makes it unsuitable for production – an important cost factor, especially for gears that have a high tooth count. For greater accuracy, centering is carried out at several circumferential positions.

Once centering is complete, profile grinding begins. Depending on requirements, this can be done with ceramic dressable wheels or with electroplated / dressable CBN wheels. The integrated measuring system can then check the first ground tooth and automatically correct it if necessary. This eliminates the need for a second corrective pass – saving both time and cost. Programming is carried out via dialog system, making setup straightforward for operators. Corrections to the tooth profiles can also be entered easily and directly on the control.

The EMAG GP 500 H was developed for the precision grinding of internal and external gears. For aerospace, helicopter and general gear manufacturing, it guarantees the highest quality, especially for components that have many interfering contours due to their design. The compact design and 5-axis technology guarantee precise results.

The GP 500 H is a highly flexible, versatile machine. Depending on the application, one or two grinding spindles with different grinding wheels sizes can be mounted on the tangential axis. The spindles can also be positioned at a 90-degree angle to each other and changed quickly, for example, when switching to an internal sanding head. The perfect machine for components with interfering contours.

All standard grinding wheels can be used. Scale and finish-machining CBN wheels on one spindle or a dressable wheel.

Single and twin spindle configurations

The GP 500 H is available in both single and twin spindle configurations. The choice depends primarily on the component requirements and the selected grinding wheel technology.

Internal gearing

Conversion from external to internal grinding can be carried out quickly, with the option to use very small grinding wheels. Internal gear cutting or spline tooth profiles can be produced with either CBN or ceramic wheels.

Quality control

A critical aspect of grinding double helical gears is the precision control of the material removal on both tooth flanks. This measurement is essential, as the position of the apex point (intersection of the two tooth profiles) depends on uniform material removal on both sides.

The measuring system of the GP 500 H includes a high-precision probe mounted on the A-axis. This probe can be swiveled out and refers to a fixed measuring point before the actual measurement begins.

Apex point control

The apex point, defined as the intersection of the two gear cutting angles in the center of the tooth, is a decisive quality parameter. Its exact position determines the running characteristics and load distribution of the gearbox. A deviation from the nominal apex point can lead to uneven load distribution, increased wear and noise. Measuring and monitoring the apex point requires high-precision measurement technology and corresponding evaluation algorithms. These are implemented in the GP 500 H control unit.

Double helical gears on a gear shaft eliminate axial forces and enable a compact, power-dense design.