In the race to stay competitive, manufacturers are always searching for equipment that balances productivity, precision and affordability. EMAG’s Classic Machine series is designed to meet this challenge head-on. The machine front and center in this lineup, the MSC 5 DUO, exemplifies how “just enough” can be more than enough – especially when built on proven technology and smart engineering.

What is the EMAG Classic Machine Series?

The Classic Series is EMAG’s answer to companies that want reliable, high-performance machinery without the cost and complexity of a fully customized solution. Designed for straightforward machining applications, these machines provide an optimal mix of functionality, cost-efficiency and serviceability.

With Classic machines like the MSC turning machine and USC universal lathe, EMAG takes a pragmatic approach: fewer options, more focus. These machines are built with standardized platforms, then enhanced with EMAG’s proven machining technologies. That means you get real-world production power, backed by EMAG’s global and local service network – but without the investment of a modular or fully customized system.

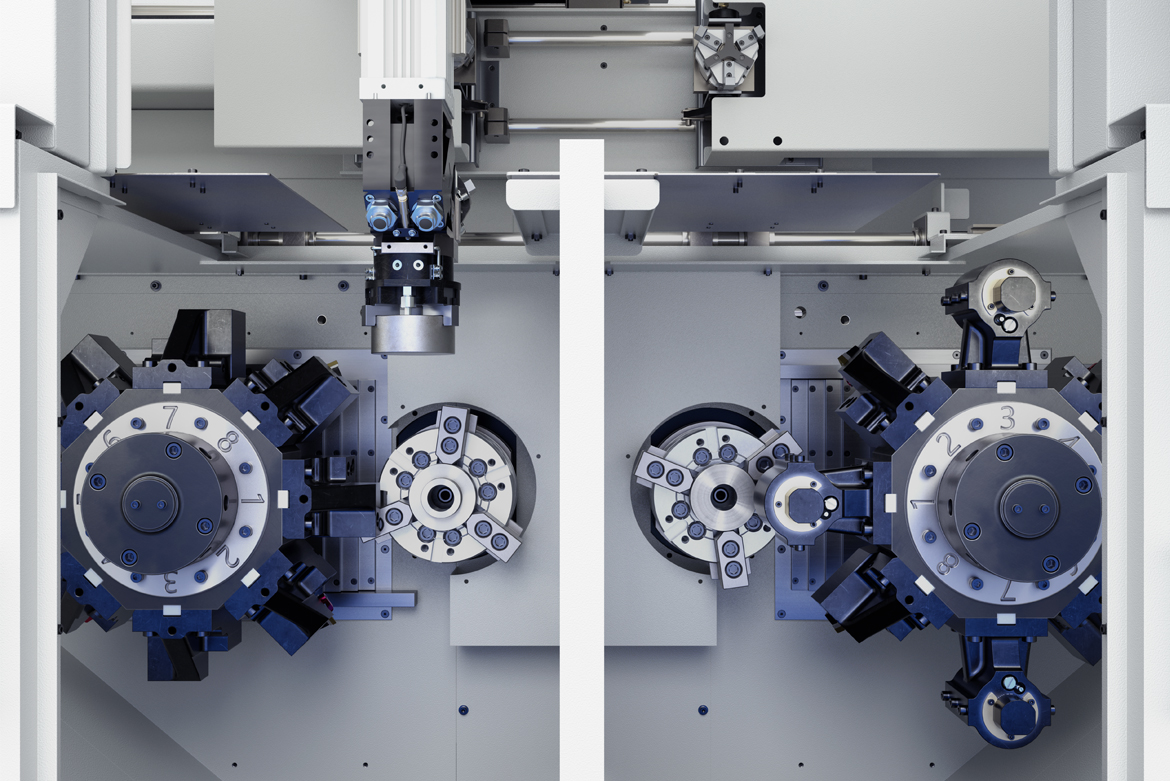

MSC 5 DUO twin-spindle CNC lathe, featuring a compact footprint, integrated gantry automation and ergonomic access for streamlined operation and maintenance.

Why the Classic Concept Matters?

- Essentials-Only Approach: By reducing the range of options to what’s truly necessary, Classic machines keep investment costs low and startup time fast.

- EMAG Quality, Simplified: The base machines come from trusted sources but are upgraded and optimized with EMAG technology before delivery.

- Local Support: Even at the Classic tier, you still get full access to EMAG’s local service, parts and technical assistance.

- Tailored to Cost-Conscious Operations: Ideal for job shops, Tier 2 suppliers and small-to-midsize manufacturers looking for maximum output at minimal complexity.

MSC 5 DUO work area featuring twin high-precision spindles, dual servo-driven turrets, and an integrated 3-axis gantry loader – engineered for high-output batch production.

Spotlight on the MSC 5 DUO: Built for Productivity?

The MSC 5 DUO is a front-loading, twin-spindle CNC lathe that represents the best of what the Classic Series offers. It’s specifically engineered for soft turning applications in industries like automotive, fluid power and general machining.

Here’s what makes it stand out:

- Twin-Spindle Efficiency: True simultaneous machining cuts cycle time in half.

- Split-Bed Precision: Physically separates machining zones to eliminate vibration transfer and maintain dimensional accuracy.

- Automation Included: A standard 3-axis gantry loader and part tuner automate handling and enable complete part machining in one setup.

- Compact Design, Big Output: The built-in stacker system allows for hours of unmanned production without expanding your footprint.

- BMT Turrets for Rigidity: Offers up to 8 tool stations with enhanced stability for better tool life and performance.

High-performance BMT turret with 8 standard tool positions – for fast tool changes and enhanced machining flexibility.

How it Fits in EMAG’s Portfolio?

Wih the MSC 5 DUO and the broader Classic Machine Series, EMAG has created a pathway to high-output, low-complexity machining. It’s the perfect solution for manufacturers who want to streamline operations without sacrificing performance or reliability.