The 47th annual SHOT Show proved once again why it is the premier event for the shooting, hunting and outdoor industries. With record-breaking exhibit space, more than 54,000 industry professionals in attendance, and groundbreaking innovations on display, this year’s event set a new benchmark for industry engagement and collaboration. For EMAG, the SHOT Show was the perfect opportunity to introduce our latest advancements in electrochemical machining (ECM) for rifle barrel manufacturing, particularly our cost-effective 2-spindle ECM rifling machine.

Introducing the 2-Spindle ECM Rifling Machine

One of the highlights of EMAG’s presence at the SHOT Show Supplier Showcase was the unveiling of our new 2-spindle ECM rifling machine. Designed for manufacturers seeking precision, efficiency and repeatability, this machine delivers the same high-performance rifling as our larger models but at a more accessible price point. ECM rifling ensures perfect internal geometries for barrels, supporting a variety of rifling profiles, including polygonal, progressive and standard rifling.

With up to eight barrels machined simultaneously, low investment costs, and a process that eliminates mechanical and thermal stress, ECM rifling offers a superior alternative to traditional hammer forging. The response from attendees was overwhelmingly positive, with many manufacturers expressing interest in how ECM can streamline their production processes while maintaining the highest standards of quality.

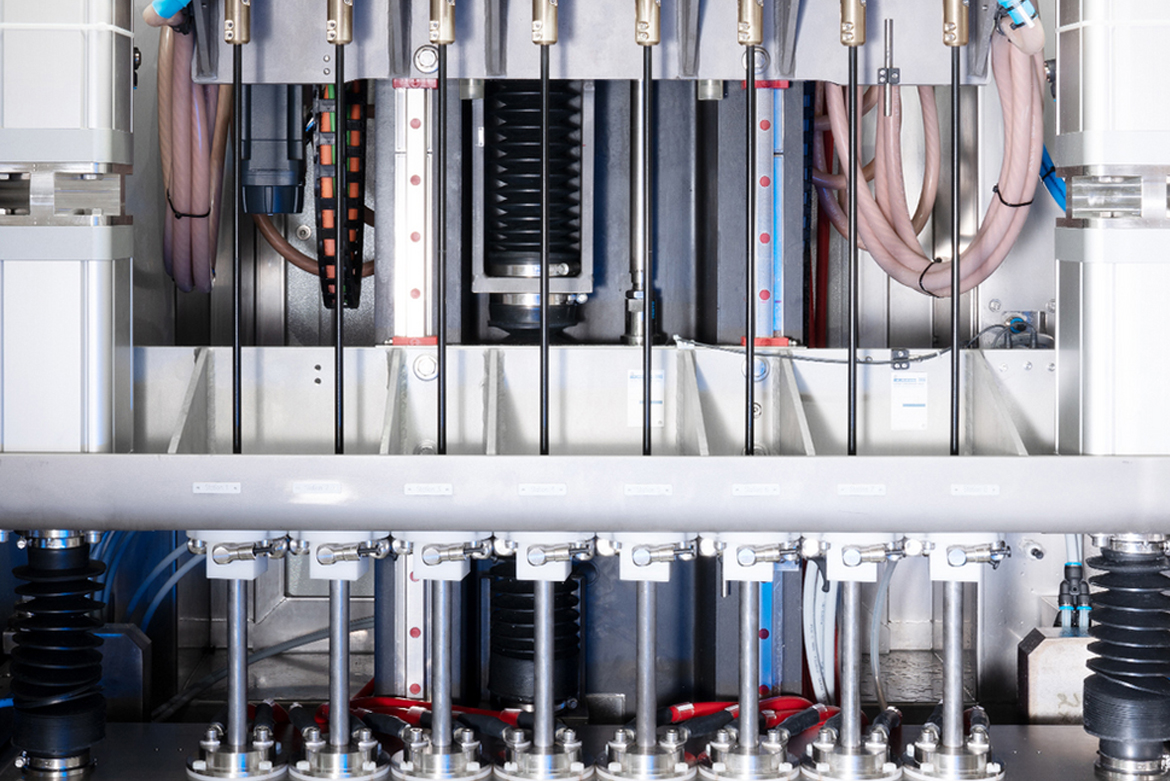

The PI ECM machine: A compact, space-saving design integrating the machining area, control unit and electrolyte management system on a single frame.

Why ECM Rifling is the Future of Barrel Manufacturing

Firearm accuracy hinges on precision engineering, and the rifling process is crucial in determining shot performance. With sporting firearms manufacturers demanding ever-tighter tolerances and repeatability, ECM rifling provides a compelling solution. Unlike conventional methods, ECM is vibration-free, operates with minimal noise, and ensures consistent precision without mechanical wear and tear. Our team of ECM specialists were on-site at booth #51217 to discuss how this technology can benefit firearm manufacturers looking to enhance their production capabilities.

EMAG Specialists, Jeremy Elder and Manuel Steinhauer at SHOT Show 2025

A Look at the Bigger Picture: SHOT Show 2025

Beyond our own exhibit, the SHOT Show itself reflected the strength and innovation within the industry. Featuring over 2,850 exhibitors, this year’s event brought together key stakeholders across the shooting, hunting and outdoor sectors, as well as law enforcement and security professionals. The Supplier Showcase provided a platform for manufacturers and OEM suppliers to connect, fostering collaboration and innovation in materials, machinery, software and logistics.

In addition to the exhibition floors, the SHOT Show continued to drive important conversations about the future of the firearm industry. The event featured the 4th Annual Governors’ Forum and the Attorneys General Forum, where policymakers and industry leaders discussed the economic impact of firearm manufacturing and regulatory considerations. These sessions underscored the industry’s commitment to responsible business practices, economic growth and legislative engagement.

Industry Highlights and EMAG’s Takeaways

An exiting addition to this year’s SHOT Show was the all-new SHOT Show eXtra Pavilion, highlighting emerging trends and first-time exhibitors. The Archery Business Pavilion also returned, further diversifying the range of innovations on display. Meanwhile, SHOT University, the Law Enforcement Education Program (LEEP), and Export Training Sessions provided valuable educational opportunities for firearm retailers, range operators and manufacturers.

For EMAG, attending the SHOT Show was about more than just showcasing our latest technology – it was about engaging with the broader industry, understanding evolving needs and strengthening relationships with manufacturers. As the firearm industry continues to evolve, precision manufacturing will remain at the heart of innovation, and we are proud to play a role in shaping its future.

Rifling module: Up to eight components are machined in parallel.

Looking Ahead to SHOT Show 2026

The energy and momentum from SHOT Show 2025 have set the stage for an exciting year ahead. EMAG remains committed to driving advancements in firearm manufacturing with cutting-edge ECM technology that enhances efficiency, precision and cost-effectiveness. As we look forward to next year’s event, we are eager to continue these conversations, explore new collaborations and further cement ECM rifling as the go-to solution for barrel manufacturing.

Thank you to all who visited us, engaged in discussions and expressed interest in our technology. The future of firearm manufacturing is bright, and we’re excited to be part of it. See you at SHOT Show 2026!