EDNA Cortex

EDNA Cortex 是一款用于数据收集、处理和准备的软件。

EDNA Cortex 软件——收集、处理和分析机床数据

EDNA Cortex 是一款用于数据收集、处理和准备的软件。

您需要使用工业计算机 EDNA Core 作为所有软件模块的基础,才能收集数据。

利用机床数据优化您的生产!

EDNA Cortex 是一款适用于埃马克机床的标准化数据采集软件,并且已经通过多项测试检验。

使用这款软件可以读取、收集和处理机床数据,并从中获得各种可优化生产的宝贵信息。

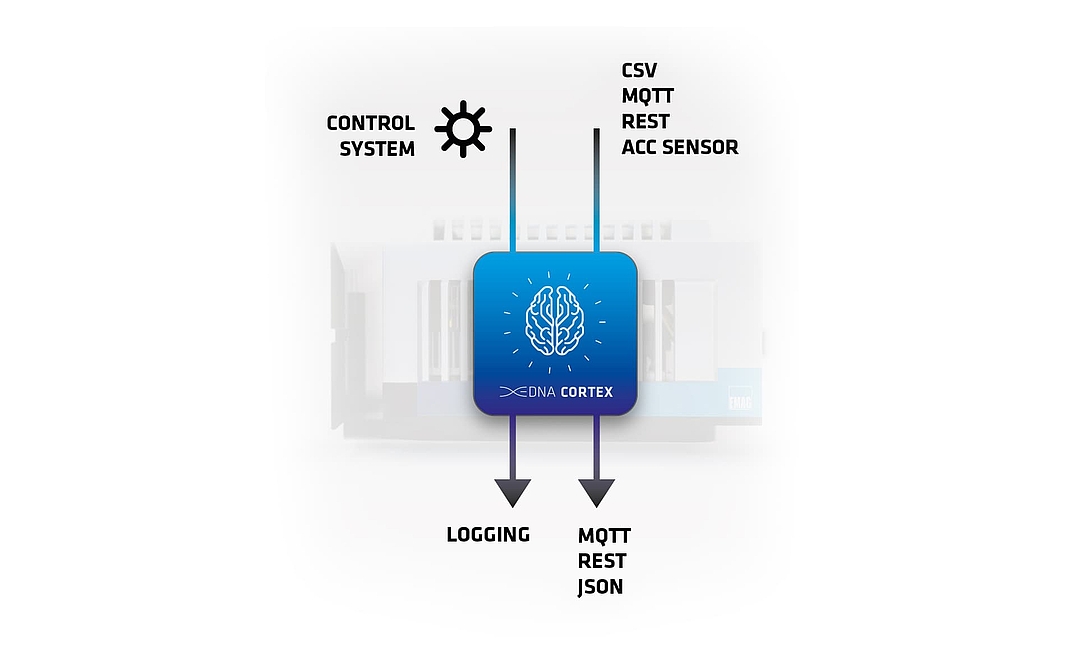

在应用过程中,软件 EDNA Cortex 会与机床控制系统通讯并处理生产数据。

软件汇总和分析收集到的数据,以优化生产设备。

特点:

- 与机床控制系统直接连接

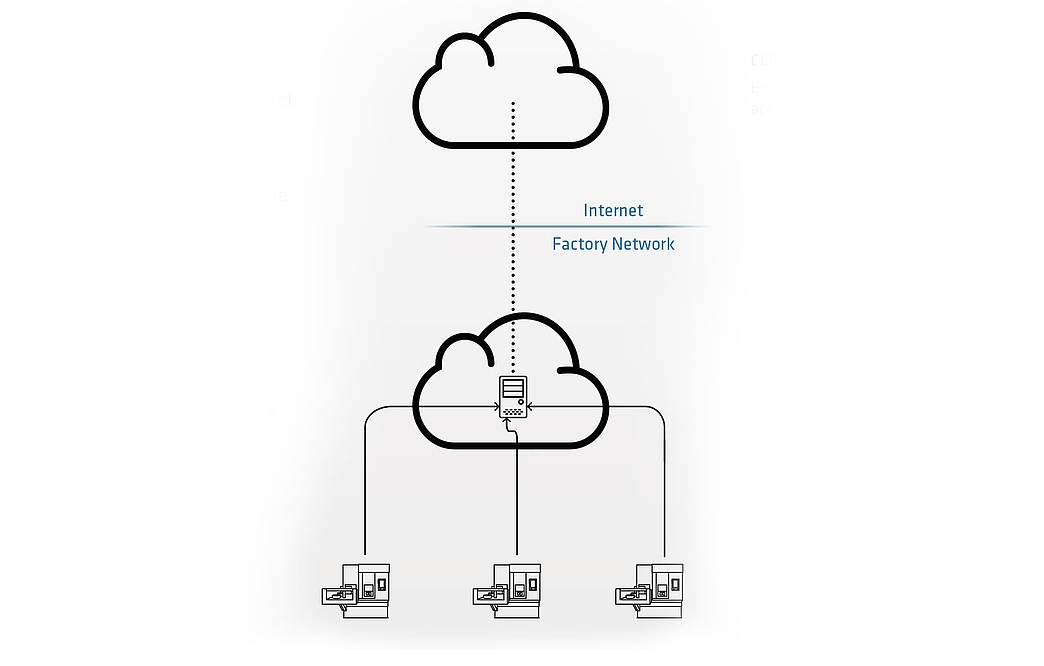

- 可扩展用于本地、边缘和云应用

- 模块化、开放式软件架构,实现特定的 IT 基础设施

- 通用的 IoT 标准接口:MQTT、Rest、Json、OPC UA

- 集成的数据科学管道

- 根据网络负载自动调整

- UMATI 立即可用

- 可连接附加装置

- 可整合其他机床制造商

为生产带来的益处:

- 安全、快速并且简单方便地访问您的机床数据

- 减少手动采集数据的工作量

- 为所有 IoT 和数据应用(本地、边缘、云)建立基础

- 诊断历史数据

- 所有机床均采用统一的数据格式,为您带来极大的益处

- 保留数据主权,不受

控制器制造商或平台制造商限制 - 快速连接现有

- 生态系统

- 利用我们的开放式接口及详细的数据描述

更新选项:

- EDNA 人工智能算法

利用人工智能检测生产中的异常情况并获得优化建议

- 状态监控

监控当前生产状态 - 预测性维护保养

重要组件的磨损情况一目了然,从而能尽早采取应对措施 - LIFELINE-DASHBOARDS

这是一种可在各种设备上直观显示所有生产和服务信息的好方法。在这一领域内,也可以实现客户定制的应用。

更多信息

硬件要求:

- EDNA Core

- 西门子、法那科控制系统

- 不间断电源