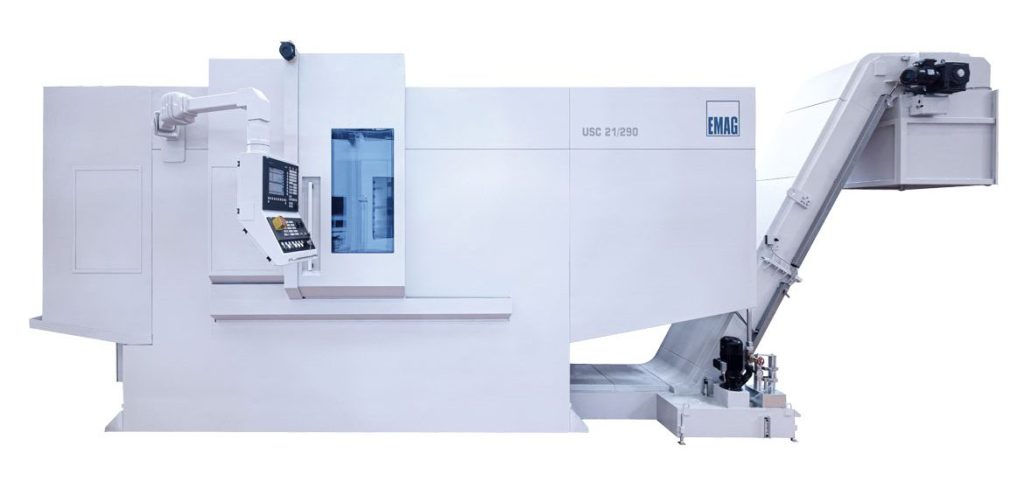

The USC 21 from EMAG is a high-performance special-purpose machine for the precise machining of pipe ends and OCTG components. It reliably and flexibly handles the full range of API, GOST, integral and premium threads – with maximum production accuracy.

The USC 21 tube processing machine from EMAG was specifically developed for the demanding complete processing of OCTG tubes. It combines flexibility, precision and productivity at the highest level. Its machine body, made from high-quality polymer concrete (MINERALIT® ) ensures maximum rigidity and optimal vibration damping. This enables consistently high dimensional accuracy and surface quality, even during heavy-duty machining processes.

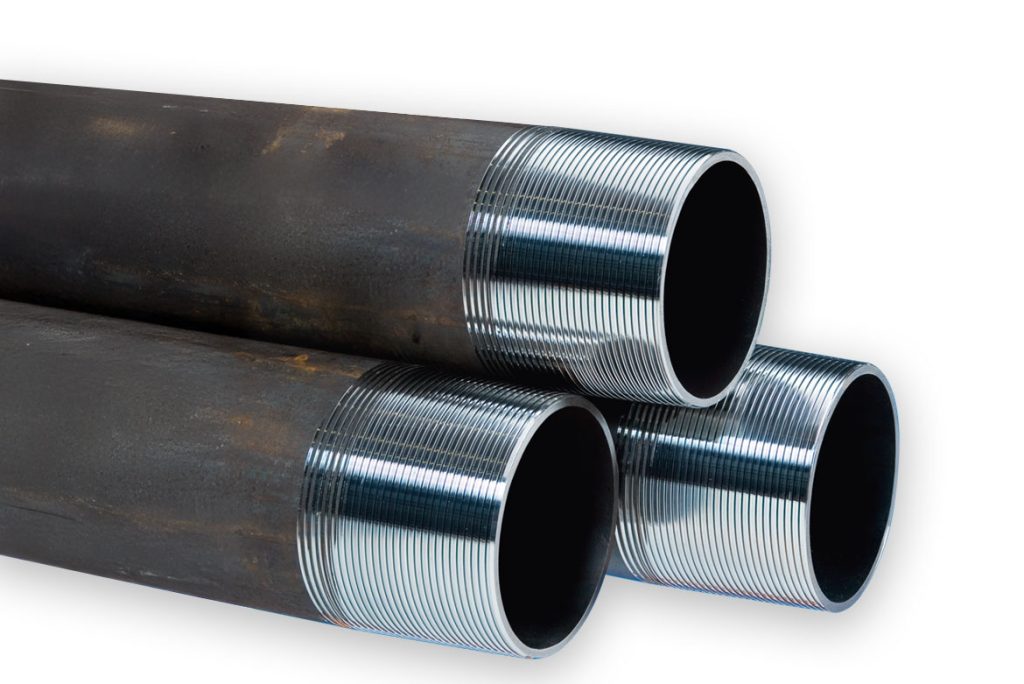

EMAG USC 21 produces high-precision API, GOST integral and premium threads for demanding applications.

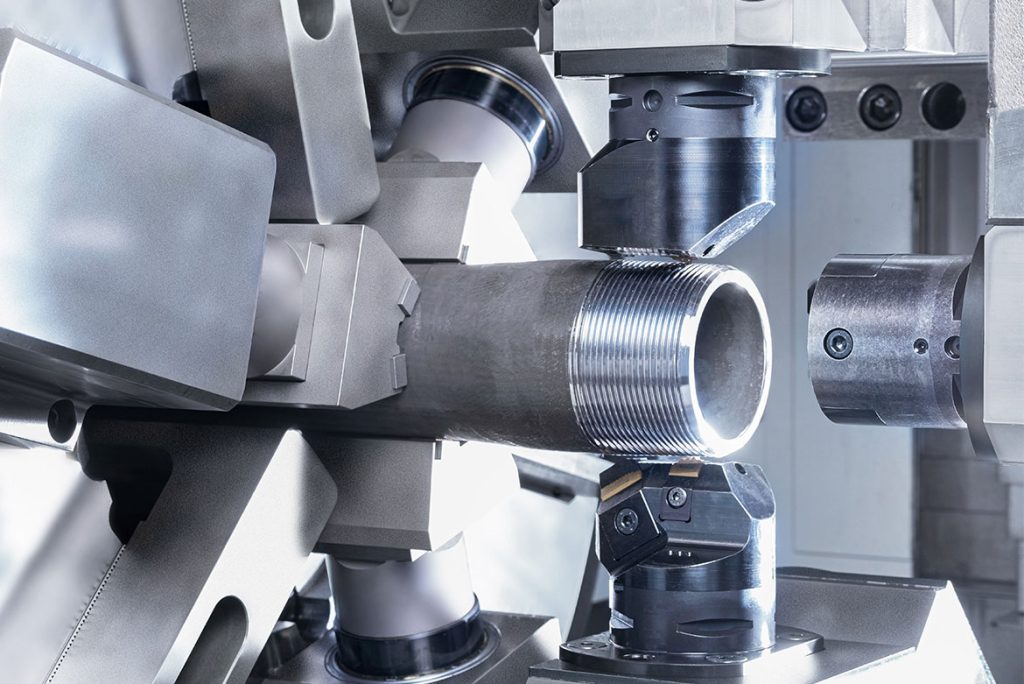

The USC 21 stands out with its unique machine design, featuring a direct-drive main spindle motor that delivers both high performance and maximum torque. The integrated direct drive technology also ensures maximum positioning accuracy during thread production.

The USC 21 features a modular design and is available in 2-axis, 4-axis and 6-axis versions. It flexibly covers all areas of application – from simple API standard threads to complex premium connections.

Two powerful, synchronized chucks (hydraulic, optionally mechanical or pneumatic) enable secure and precise workpiece clamping, while separate NC-controlled centering and support units provide additional stabilization of the tube.

Thanks to the ability to perform simultaneous machining with multiple tools (4- and 6-axis versions), productivity is noticeably increased and cycle times significantly reduced. This makes the USC 21 an ideal choice for production lines with high production capacity and demanding quality standards.

Front view of the USC 21 from EMAG – modular, robust and designed for flexible machining

Your advantages:

- Maximum precision for all thread types (API, GOST, Premium, Integral)

- Modular design: 2-axis, 4-axis and 6-axis machining options

- Rigid machine body made of MINERALIT polymer concrete ®

- Powerful integrated direct drive with high positioning accuracy

- Optimal chip fall thanks to vertical machining orientation

- Precise, reliable pipe clamping with double chuck system

- Liquid-cooled components for maximum thermal stability

- Ideal for flexible integration into automated production lines

- Reduced cycle times through simultaneous multi-tool machining

The working area of the USC 21 enables parallel processing steps for minimum cycle times.

Technical data

| USC 21 | 290 | 450 | |

| Nominal Ø | inch | 2-3/8 – 10-3/4 | 4-1/2 – 16 |

| Spindle Ø max. | mm | 290 | 450 |

| Travel X | mm | 350 | 350 |

| Travel Z | mm | 600 | 600 |

| Main drive power | kW | 120 | 120 |