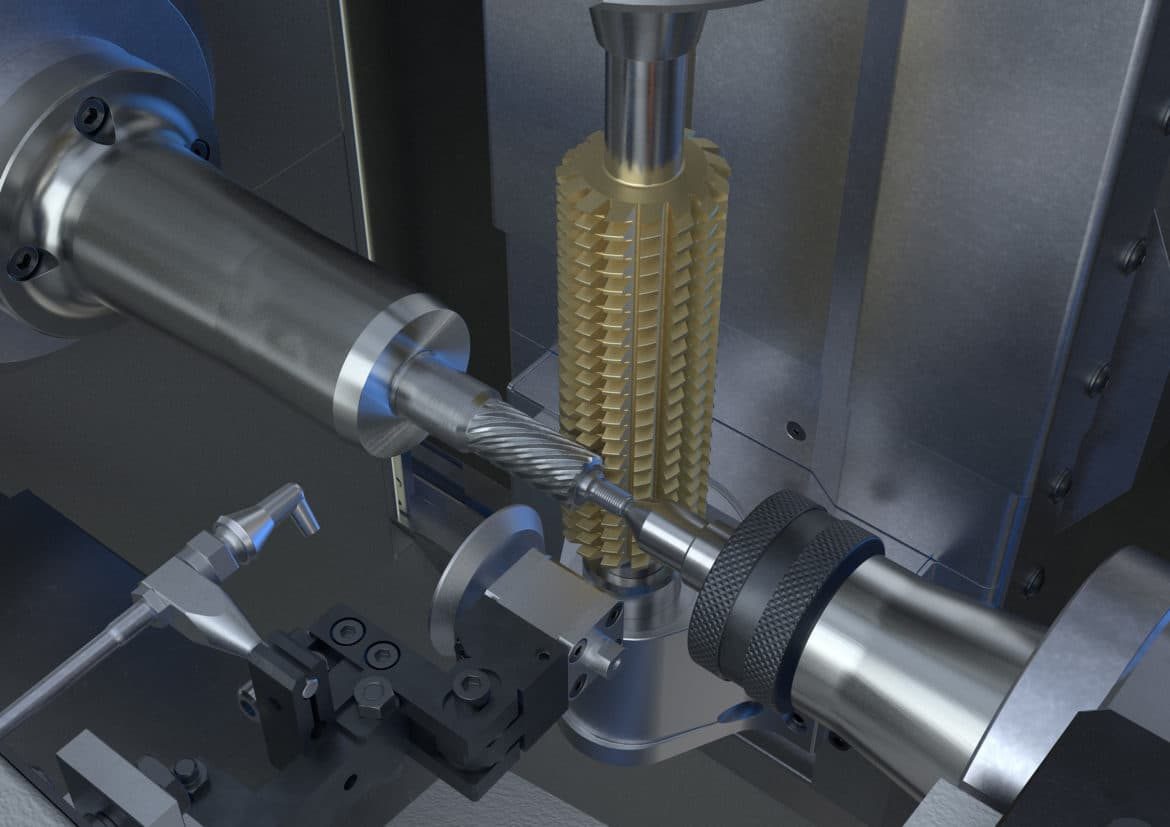

Find out more about the design and development of the VLC 350 GT turning/grinding center in our interview with Manfred Winkler, Head of Technical Sales, Business Unit Grinding. The VLC GT series from EMAG is one of the most successful new developments in recent years. The combination of proven pick-up automation, vertical machining and the ability to use various hard machining technologies in the spacious work area has made some great manufacturing solutions possible. We spoke to Manfred Winkler about the machine and the ideas behind the new development.

turning and grinding machine

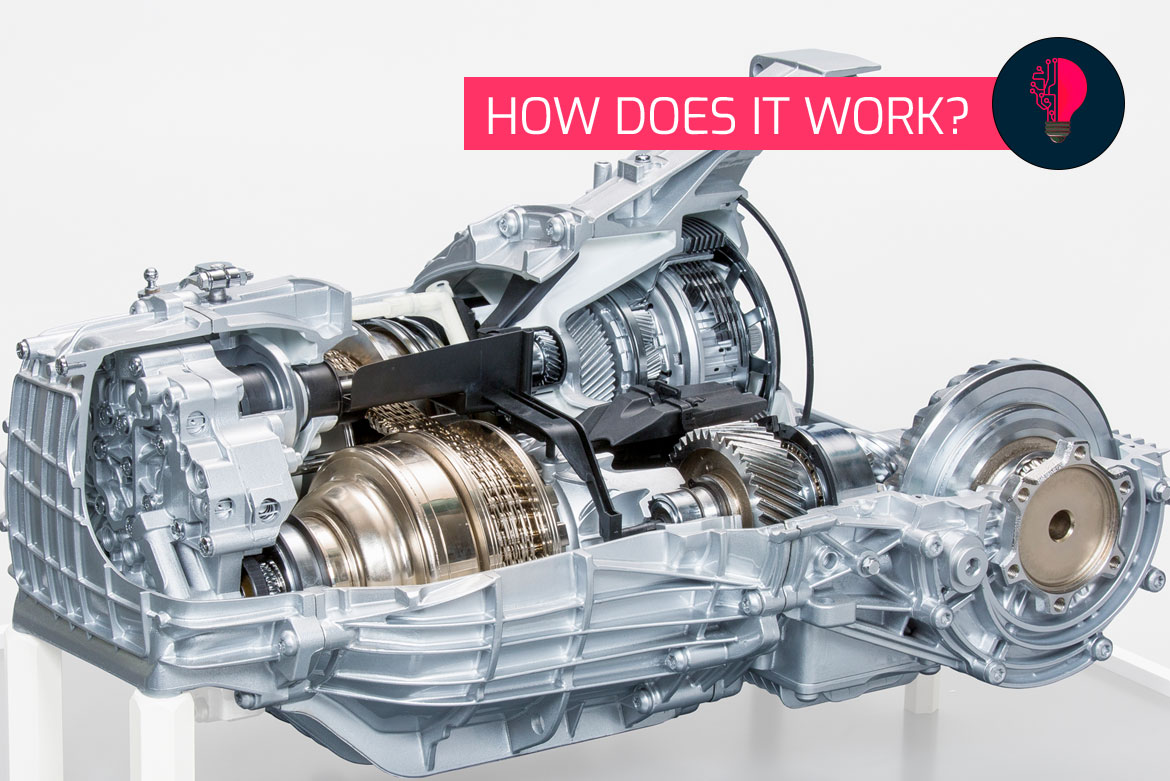

The forces in a transmission are not always transmitted with the help of gears. There are exceptions, such as the CVT transmission, in which a steel belt or a multi-plate chain moves on conical pulleys. We explain exactly how this works here. There is also some interesting information about this invention, which dates back to the 19th century.

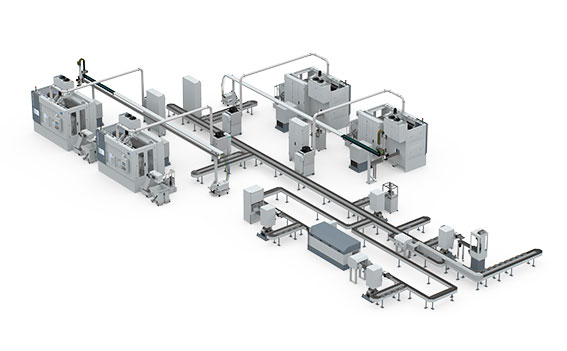

For over 50 years, Kordel has developed a variety of drive systems and transmissions used in agricultural and construction equipment, as well as industrial trucks. This is a task that requires both robust machining and precision, simultaneously. The family-owned business with its headquarters in Dülmen near Münster, Germany relies on the competence of its employees, flat hierarchies and a high level of integration with a “state-of-the-art” machine system. For over 20 years, EMAG’s pick-up technology has played a major role at Kordel. More than 17 production solutions from the Southern German machine builders are used at the production sites in both Germany and Poland. The most recent additions are two VLC 200 GT turn-grind centers. Below is a conversation we had with the Kordel Managing Director, Johannes Kordel, about the success of his company, and the important part mechanical engineering has played in it.

Development of the new VLC 350 GT Turning/Grinding Center – Interview with Marina Manger

The VLC GT series is one of the most successful new product developments for EMAG in recent years. The combination of the proven pick-up automation system, vertical machining operation and the option of using different technologies for hard machining in the spacious machining area, has made some fantastic production solutions possible.

With the VLC 350 GT, the next biggest expansion stage is being launched. We spoke to Marina Manger, assistant team leader of the TPM-1 application team, about the new machine and the ideas its development was based on.

In the past year, for the first time ever, more than 2 million electric vehicles were sold worldwide as reported by the Center of Automotive Management (CAM). With 60% of the worldwide demand, China is the main driver of this development.

Electric power steering has become standard in the manufacturing of automobiles. The technology guarantees very precise steering support for every type of vehicle, high-end driving comfort, and lower energy consumption in the steering system, which has a positive effect on the car’s CO2 consumption.

CVT transmissions are becoming increasingly popular in the American and Asian markets. The technology improves driving comfort as the car shifts gears more smoothly. A critical part of manufacturing these transmissions is the creation of the CVT components like shafts and disks (“pulleys”) that need to be hard machined with extreme precision– all as part of a multi-stage process that uses various turning centers and grinding machines.

The VLC 200 GT is loaded at by the integrated pick-up spindle. The process starts with hard pre-turning of the shoulder and the bore hole in quick succession. Only a few micrometers of material are then left to be removed from the automotive gear by the subsequent grinding process, using either aluminum oxide or CBN grinding wheels.

Transmission manufacturing is among the most innovative areas of passenger vehicle production: This central component has to ensure a high level of driving dynamics, while keeping fuel consumption low at the same time. Transmissions are therefore becoming smaller and lighter, and provide a higher number of speeds. The individual gearwheels are a main focus of the developers. Their production in extremely high volumes requires a high level of efficiency—at high precision, high speed, and highly controlled.