1. Name

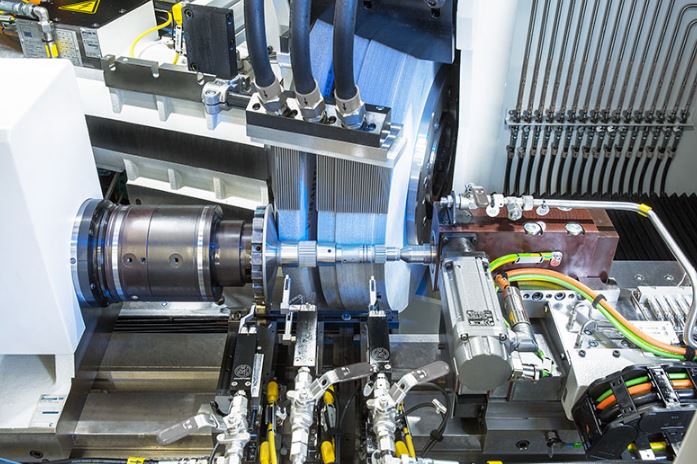

In a traditional automatic transmission, a torque converter is installed between the engine and transmission. This core component contains an impeller, turbine wheel and a guide wheel. Driven by the engine, the impeller blade catch oil in the housing which creates a flow that will delayed drive the turbine wheel. This principle ensures a smooth startup and separates the drive train from the engine’s vibrations (referred to as engine irregularities).