Daniel Rujanoski is Director of Global Sales & Applications at EMAG LaserTec and is responsible for technical sales and the Laser Application Center. In this interview, the expert in laser welding technology explains the technical features and cost-saving advantages of the new ELC 6i – a standardized laser welding cell for powertrain components.

Mr Rujanoski, the ELC 6i marks a paradigm shift from customer-specific individual solutions to a standardized system concept. What were the key drivers behind this strategic change?

The decision was based on a systematic analysis of market requirements over the past few years. Over the past two decades, we have implemented a large number of laser welding systems for powertrain components – most of them unique, one-off solutions with tailored process sequences and individual automation concepts. Every system looked different, and genuine repeat systems were rare. Such special solutions are generally associated with greater complexity, considerable engineering effort and correspondingly long delivery times.

At the same time, we are feeling the strong increase in cost pressure from our customers. The current discussion about the competitiveness of Germany and Europe as a business location is further amplifying this trend. We wanted to provide an answer to this with the ELC 6i. The concept was not created from scratch, but through the consistent analysis and standardization of proven process steps from our existing systems.

The ELC 6i is a standardized laser welding system for powertrain components. It integrates up to six process steps in one compact machine. The overall enclosure ensures laser safety and reduces the footprint.

What basic technical principles did you follow when designing the ELC 6i?

The central design principle was the integration of multiple processing steps in a uniform system with a continuous material flow. We deliberately decided against the concept of linked individual machines and instead developed a fixed cycle transport system that links all the process steps together.

The technical basis is a rotary indexing system with 14 to 18 workpiece holders, depending on the system configuration. The system rotates counter-clockwise and advances two positions at a time. This configuration enables parallel processing steps and minimizes non-productive times through optimized workpiece distribution. Even extensive process chains with up to six individual steps can be processed in less than 20 seconds cycle time.

The ELC 6i achieves a 36% space savings compared to conventional solutions. How did you technically realize such a compact design?

The space optimization is the result of several design measures. First, we integrated all process steps within a single, unified housing. This enclosure fulfills both the laser safety requirements for up to three laser processes and the role of a safety fence – eliminating the need for separate safety cabins for each individual operation.

With a footprint of 21.4 m², the ELC 6i requires significantly less space than conventional solutions. We have achieved this compactness without sacrificing any functions. On the contrary: all the necessary process steps are fully integrated. The continuous material flow also eliminates the need for intermediate buffers or complex transfer systems.

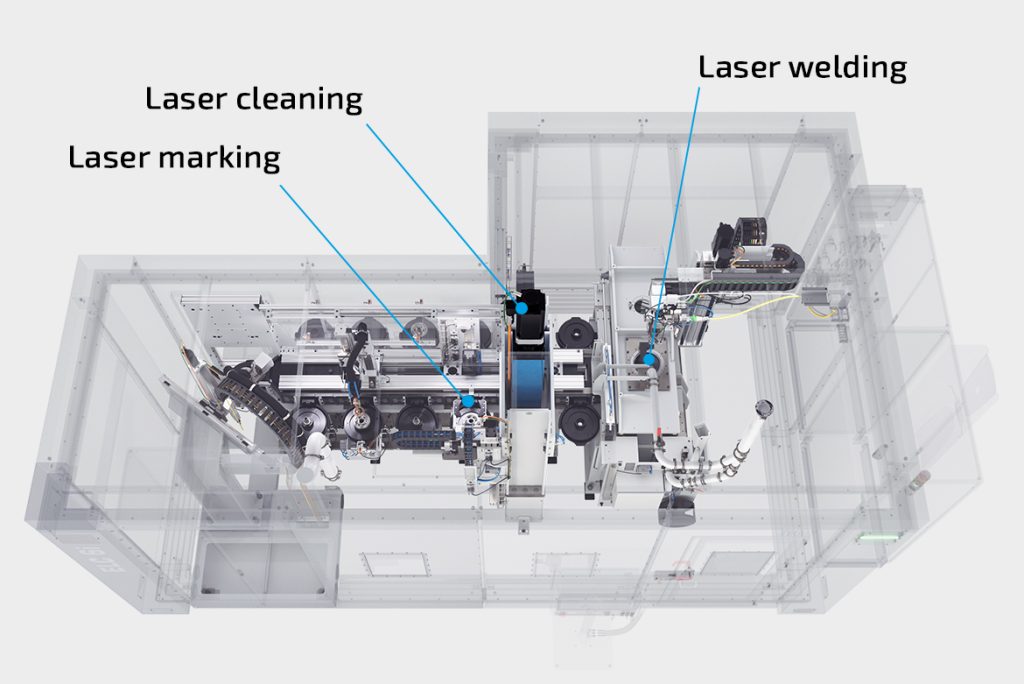

Schematic representation of the ELC 6i with integrated stations for laser cleaning, laser welding and laser marking. The compact overall enclosure replaces individual safety fence systems. All processes take place within a closed safety room.

What exactly does the process sequence in the system look like?

The process chain begins with the placement of the two individual components – for example a differential housing and a spur gear. This is followed by laser cleaning of both joining surfaces. This is performed by a pendulum optic mounted on an X-Z-B kinematic system that oscillates between the two workpiece carriers. If necessary, an initial preheating process can follow to reduce the pressing force needed during joining. The components are then joined in a servo-mechanical unit. Optionally, a second preheating process follows, specifically in preparation for the welding process. In the next step, the weld seam is applied using a laser beam. Finally, the components can be laser-marked for component tracking and removed from the system.

The illustration shows the complete process chain of the ELC 6i – from laser cleaning to joining and laser welding. Preheating and testing processes as well as laser marking for component identification can be integrated as an option. All steps are automated within the system.

What about flexibility and changeover capability?

Although the ELC 6i follows astandardized concept, it is by no means inflexible. Different component geometries can be mapped within the defined process framework. For similar components, no retooling is required at all. If there are major differences, we are talking about changeover times of around 20 minutes. It’s modular design is key. Both the cleaning and welding processes are freely programmable via the system’s axes, and the pressing tool can be adapted to the specific workpiece. The chuck can also be swapped quickly thanks to integrated quick-change systems. This makes the system ideal for platform strategies in which different component variants are produced with one basic concept.

What role does the control system play in process reliability?

The entire system is operated via a central CNC control system (Sinumerik One). This simplifies programming and significantly reduces software complexity compared to systems with several decentralized controllers. For the customer, this means fewer interfaces, fewer sources of error and shorter commissioning times. At the same time, all stations are integrated into the control system via standardized function blocks – from handling to the laser system to marking. This ensures a uniform operating concept and makes servicing and maintenance easier.

For which quantity ranges can the ELC 6i be used economically?

The ELC 6i is primarily designed for high quantities. It becomes clearly economical starting at around 100,000 units per year. The concept targets applications where cost pressure and productivity are crucial. For lower quantities, our modular and customer-specific solutions are often the better choice.

Cost-effectiveness increases with the number of integrated process steps. The system shows its full potential from three processes upwards. The more process steps are integrated, the greater the cost and space-saving benefits.

What specific cost benefits can customers expect?

We have carried out a detailed profitability analysis based on unit production costs. The savings result from several factors: reduced depreciation costs due to 10-15% lower capital investments, reduced space costs due to the 33-36% smaller installation area and optimized maintenance efforts due to standardized assemblies.

Overall, we see a potential reduction in unit costs of up to 15%. In addition, delivery times are reduced by around 20% – from a typical 13 months to less than 12 months. This is largely possible because we can rely on predefined hardware components and standardized software modules.

How does the Laser Application Center support customers in process development?

Our LAC in Heubach is a central component of our technology partnership. We have various laser beam welding systems with disk, fibre and diode lasers ranging from 200 watts to 24 kW. We also have laser cleaning systems, an ultrasonic testing system and extensive metallographic testing facilities.

Within this environment, we conduct feasibility studies, develop processes with customers, and, when needed, produce prototypes or small series. The special feature is that we use the same technology cells that are later used in the production systems. This ensures that all process results are directly transferable to series production.

In the EMAG Laser Application Center (LAC), laser welding processes are developed, tested and optimized together with the customer. Equipped with state-of-the-art technology, the LAC supports process design, prototype manufacture and series preparation.

The automotive industry is changing. How future-proof is a concept that focuses on powertrain components?

This is a legitimate question that we have discussed intensively. First of all, it has to be realistically stated that the combustion engine will remain an important drive for many years to come – even in hybrid drive concepts. At the same time, new applications for laser welding technology are emerging in the field of electromobility.

The ELC 6i is highly adaptable thanks to its modular concept. Rotor shafts for electric motors, for example, are already a typical application. The basic process steps – cleaning, heating, joining, welding – remain relevant even with new drive technologies.

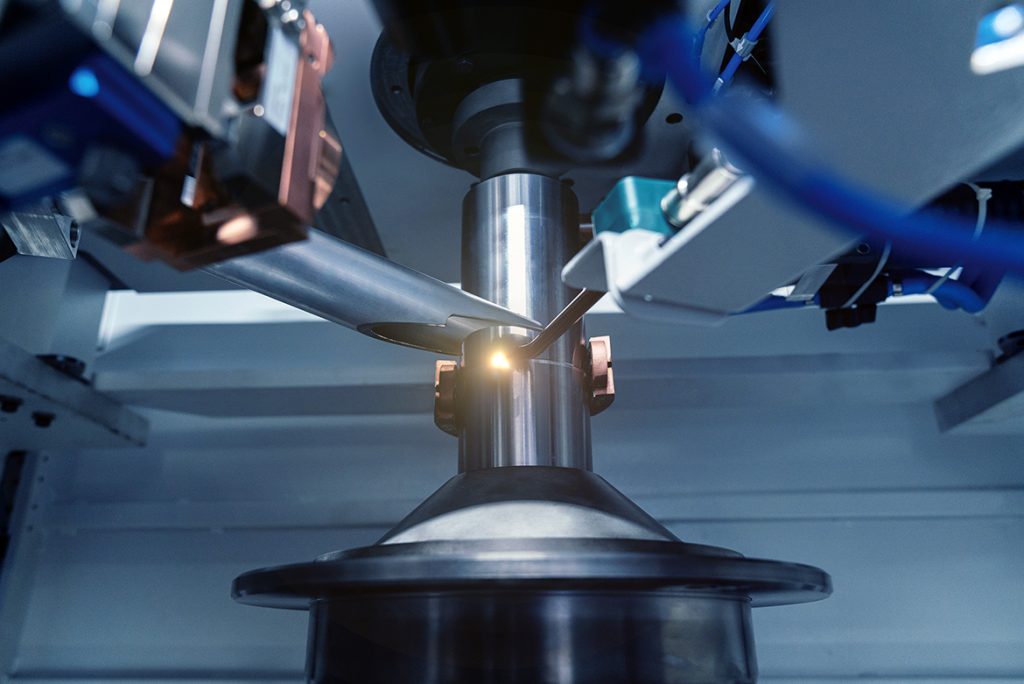

Laser welding process of a rotor shaft in the ELC 6i: Precision laser guidance and a stable process sequence ensure reproducible seam quality with minimal component distortion.

What role do process monitoring and quality assurance play?

Quality assurance is a critical factor in batch production, and the ELC 6i supports this with a wide range of integrated monitoring systems. Proven technologies such as OCT (optical coherence tomography) or the tried-and-tested LWM (laser weld monitoring) are available for laser welding. Force-controlled press monitoring documents the joining quality, while temperature monitoring at the preheating stations ensures constant process conditions. Optionally, an axial run-out test can be integrated after joining to verify the correct positioning of the component partners.

For downstream testing, we have developed concepts for ultrasonic testing and other non-destructive testing methods that can be integrated into the overall system.

How do you assess the market potential of the ELC 6i?

We see considerable potential, especially in the current market environment. Cost pressure in the automotive industry is real and will intensify in the coming years. At the same time, the demand for standardized, cost-efficient solutions is increasing. Now more than ever, “only those who have their production costs under control will remain competitive in the long term”.

The ELC 6i is already available, and we are actively working on multiple projects using this new machine concept. We are excited to bring this solution to the market together with our customers. Early feedback from initial users already confirms our view: the ELC 6i delivers real added value.

Mr. Rujanoski, thank you very much for the detailed interview.

Personal details: Daniel Rujanoski is Director Global Sales & Applications at EMAG LaserTec and is responsible for technical sales and the laser application laboratory in Heubach. Together with his teams and our customers, the expert in laser welding technology develops process concepts and system solutions for the batch production of drive components.

f.l.t.r. Oliver Hagenlocher Head of Marketing at EMAG, Daniel Rujanoski Director Global Sales & Applications at EMAG LaserTec