Vertical pick-up turning machines are indispensable in modern manufacturing. These machines often produce in three-shift operation and are already highly optimized for specific production requirements. But how can additional increases in performance be achieved with such highly developed manufacturing systems? Jürgen Maier, Head of the Turning Business Unit at EMAG, deals with this question. In the following interview, you will learn how productivity can be further increased by direct loading into the work spindle of a vertical turning machine using a robot.

Technologies

Precision plays a decisive role in the manufacture of weapons. One technique that contributes significantly to the precision of firearms is rifling – the insertion of helical flutes into the barrel of a weapon. The rifling ensures that the bullet rotates when fired and hits its target with precision. Traditionally, rifling used to be produced by mechanical processes such as hammering. Or button broaching. However, with the further development of technology, electrochemical machining (ECM) is establishing itself as a superior alternative that enables much greater precision.

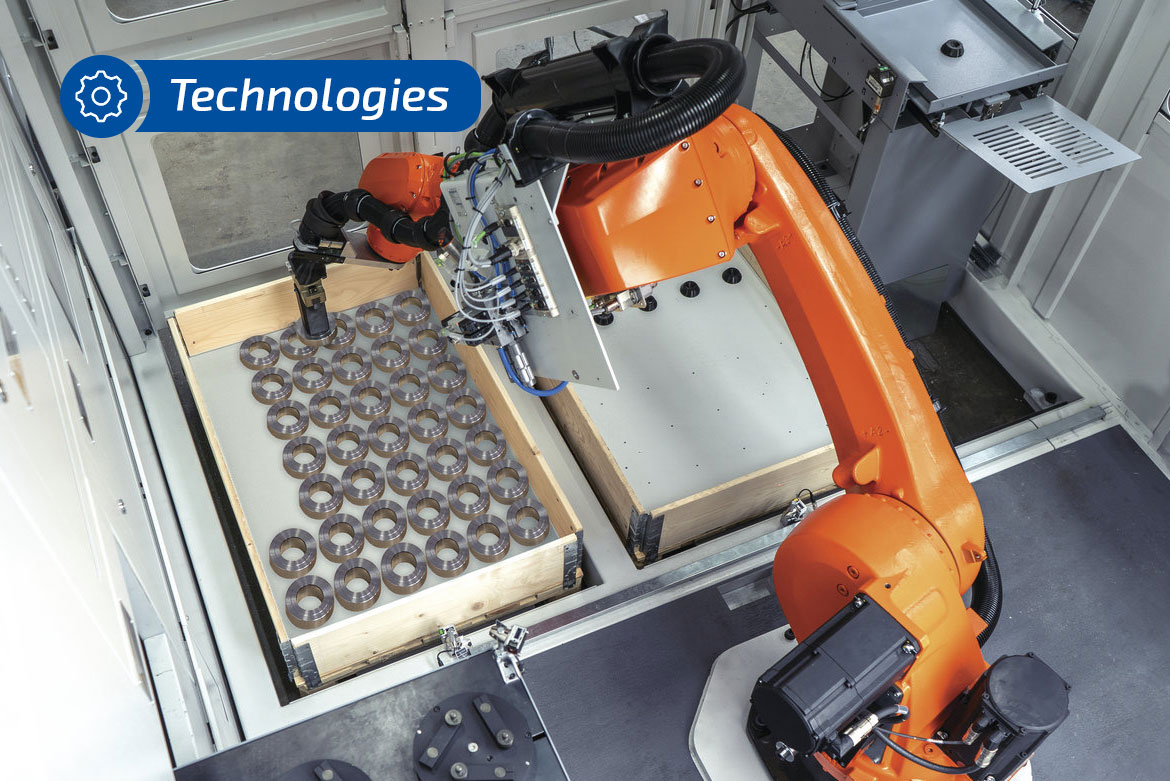

“Our customers are faced with the task of manufacturing complex components to the highest quality and in the shortest possible time. As a product manager, I support them in optimizing their production processes. With our new robot cells, we offer tailor-made solutions that not only increase productivity, but also improve working conditions. For us, automation is not just about technology, but about looking at the entire value chain.” Jan Gotthold, Product Manager in the EDNA Automation team, gives insight into the new robot cells from EMAG. In the following interview he explains why they offer real added value for many applications.

The automotive industry is facing a major challenge: the Euro 7 standard stipulates strict limits for particulate matter emissions. Cars will then only be allowed to emit around three milligrams of particulate matter per kilometer – a drastic reduction compared to today’s values of up to 40 milligrams. To achieve these ambitious targets, car manufacturers are increasingly relying on innovative technologies such as coated brake discs.

Laser cladding is a promising process for manufacturing these ultra-modern brake discs. In this application, a special material powder made of stainless steel and hard carbide is welded onto the surface of the brake disc using a laser. The result is brake systems that not only drastically reduce particulate emissions, but also minimize wear and prevent corrosion.

However, the design and development of this new coating technology also creates new challenges in post-processing. With the VLC 450 DG grinding machine, EMAG offers a specialized solution for the machining of these high-tech brake discs.

We spoke with Jannik Röttger, Head of Grinding Technology at EMAG, about this innovative technology and EMAG’s response to the challenges of the Euro 7 standard.

The 47th annual SHOT Show proved once again why it is the premier event for the shooting, hunting and outdoor industries. With record-breaking exhibit space, more than 54,000 industry professionals in attendance, and groundbreaking innovations on display, this year’s event set a new benchmark for industry engagement and collaboration. For EMAG, the SHOT Show was the perfect opportunity to introduce our latest advancements in electrochemical machining (ECM) for rifle barrel manufacturing, particularly our cost-effective 2-spindle ECM rifling machine.

At its core, cylindrical grinding is all about precision. This process involves machining the external or internal surface of a cylindrical workpiece using grinding machines equipped with rotating wheels. These machines remove material through abrasion, delivering exact dimensions and smooth finishes. Whether it’s external or internal grinding – or even a mix of both – this technique plays a pivotal role in producing high-quality parts for industries like automotive, aerospace and more.

Imagine your old machine tool suddenly being able to do more than ever before – and with less energy consumption. What sounds like a dream has become reality with EMAG’s retrofit solutions. In this interview, Markus Heidel, Head of the Retrofit Business Unit at EMAG, explains how used machines can be turned into real speedsters and why this concept will shape the future of mechanical engineering.

With the introduction of the EURO 7 standard, braking systems in cars will have to undergo massive changes, as this is the first time that particulate emissions have been regulated and many current models do not meet these requirements with their brakes. What does this mean in concrete terms for automotive production, what role does the hard coating of brake discs play and why is EMAG’s new laser metal deposition technology the ideal solution? An interview with Dominic Grimminger, brake disc coating expert at EMAG.

ECM is an innovative technology for machining the barrels of sporting guns. A special rifling module is used in the PI machine. The result is a highly precise and homogeneous field rifling profile for short and long barrels.

Alexander Morhard, Technical Sales Support Manager at EMAG SU, talks in an interview about the G 160 gear generating grinding machine, the fastest machine of its kind for gear production. He provides insights into the innovative axis concept, the high gear quality and the wide range of possible applications in gear manufacturing and electromobility.