Imagine your old machine tool suddenly being able to do more than ever before – and with less energy consumption. What sounds like a dream has become reality with EMAG’s retrofit solutions. In this interview, Markus Heidel, Head of the Retrofit Business Unit at EMAG, explains how used machines can be turned into real speedsters and why this concept will shape the future of mechanical engineering.

Oliver Hagenlocher

With the introduction of the EURO 7 standard, braking systems in cars will have to undergo massive changes, as this is the first time that particulate emissions have been regulated and many current models do not meet these requirements with their brakes. What does this mean in concrete terms for automotive production, what role does the hard coating of brake discs play and why is EMAG’s new laser metal deposition technology the ideal solution? An interview with Dominic Grimminger, brake disc coating expert at EMAG.

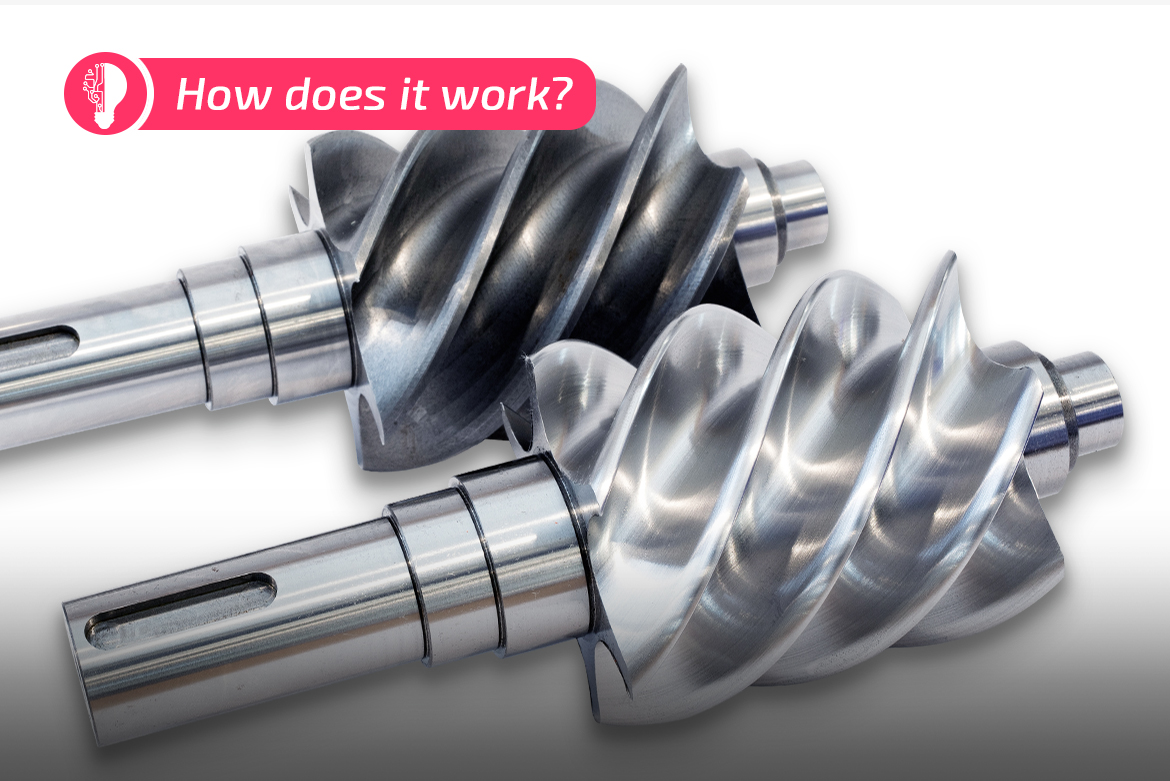

Compressors have been around for thousands (!) of years – as an indispensable aid in the production of high-quality metals. Modern screw compressors, on the other hand, are a relatively new invention from the 20th century. What distinguishes the technology in detail and where is it used today? Answers can be found here!

ECM is an innovative technology for machining the barrels of sporting guns. A special rifling module is used in the PI machine. The result is a highly precise and homogeneous field rifling profile for short and long barrels.

Alexander Morhard, Technical Sales Support Manager at EMAG SU, talks in an interview about the G 160 gear generating grinding machine, the fastest machine of its kind for gear production. He provides insights into the innovative axis concept, the high gear quality and the wide range of possible applications in gear manufacturing and electromobility.

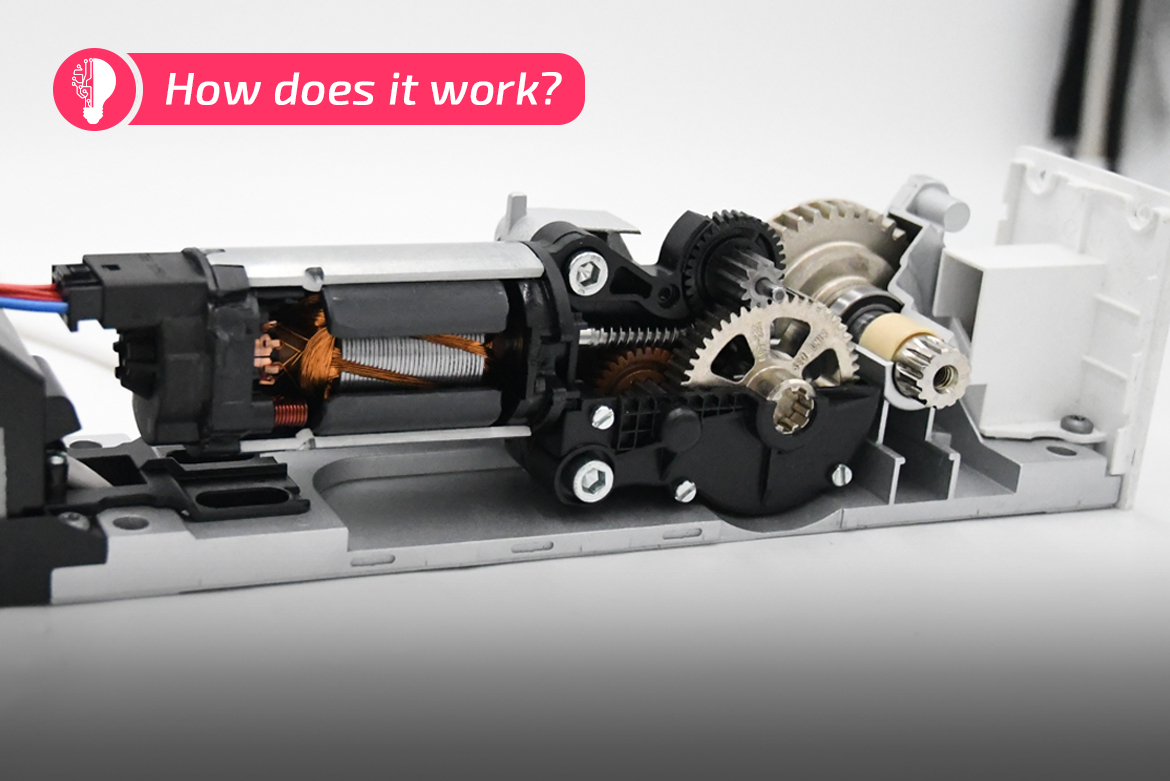

Automatic doors are familiar from hospitals, for example: after briefly pressing a button on the wall, the structure opens automatically, which is a great help when transporting beds, for example. Automatic door openers of a similar type can also be found in many companies and stores, at airports, as “airlocks” in research stations and in front of barrier-free toilets. A sophisticated gearbox usually operates inside them.

With the new VST 50 machine, EMAG is for the first time tackling a task that is as special as it is demanding: the machining of ball pins and ball sleeves. In the steering or suspension of cars, for example, these components are indispensable. What are the details of the VST 50 and how can extreme chip-to-chip times of less than two seconds be achieved in this field? Read more about this challenge in our conversation with Dr. Mathias Klein, CSO of the EMAG Group.

In the world of high precision drives, Zoerkler is a name synonymous with innovation, quality and technical excellence. In its almost 120-year history, the company has developed from a modest mechanical engineers’ workshop into a leading supplier of drive systems for the automotive and aviation industries. In this interview, Managing Director Bernhard Wagner provides insights into the fascinating world of precision manufacturing, innovative production technologies and the future visions of Zoerkler Gears GmbH & Co KG.

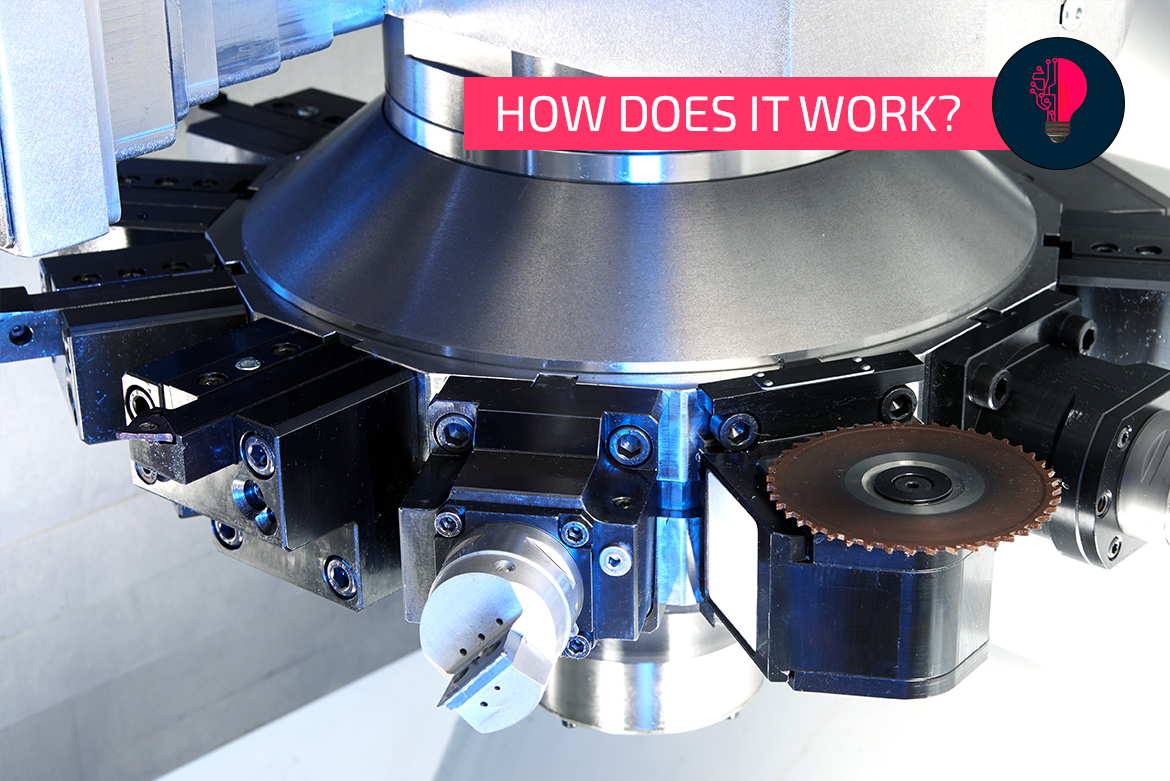

Actually, the turret inside a machine tool bears little resemblance to the barrel of a firearm in purely visual terms. So where does this name come from? We explain this in the following “How it works” blog. The same applies to the questions of how the whole thing works in detail and who invented it. Incidentally, the latter has a lot to do with the history of EMAG.

How can particularly large and heavy components be produced using lean production solutions? This question is becoming increasingly important, especially in the commercial vehicle sector, because price pressure in the market demands the lowest possible unit production costs. In this context, the VSC 500 and VSC 500 DUO machines from EMAG are real “game changers” for manufacturers. They load themselves and then ensure fast and precision complete-machining in a single setup or two. A conversation with Peter Gröner from the Turning Business Unit at EMAG about the enormous possibilities of this technology.