As automation continues to expand in industrial manufacturing, companies face clear demands: short commissioning times, high flexibility with changing workpieces and seamless integration into existing production environments. The MRC – Modular Robot Cell, was developed specifically to meet these requirements, offering a flexible automation solution for automated workpiece handling in machining production.

The MRC was first introduced as a bin-picking solution, but has been designed from the beginning as a universally applicable automation system. The modular design allows different applications to be implemented using standardized modules, making it easy to adapt the systemto new tasks without major redesigns.

Design structure and key technical data

A key feature of the MRC is its compact, transport-optimized design. With a width of 2.70 meters, the robot cell can be transported by truck as a complete unit – no dismantling required. All modules are mounted on a common base plate, which is both crane- and forklift-compatible.

The MRC modular robot cell from EMAG for automated workpiece handling. Compact design meets flexible automation concepts.

This design enables full pre-commissioning. Processes, motion sequences, gripper functions and interfaces can be set up and tested in advance. On site, customer effort is limited to aligning and connecting utilities such as compressed air, network and electricity. As a result, commissioning times are significantly reduced.

This concept has already proven itself in practice: In customer applications, the MRC was fully commissioned within a few days of delivery – allowing for faster ramp-up and predictable implementation of automation projects.

MRC as a building block of modern automation

The MRC is designed as an open automation system. Rather than focusing on a single process, it enables the integration of multiple production technologies as well as possible secondary processes. This applies in particular to the connection to upstream feed systems.

The robot cell can be combined with various material supply solutions including:

- Pallets to pallet cages and small load carriers

- Set products and bulk goods

- Manual or automated feeding via automated guided vehicles (AGV),

- Customized feeding solutions from external suppliers.

The feeding technology used is usually specified by the operator. The MRC is designed in such a way that these systems can be connected without complex adaptations. This makes the robot cell suitable both for new systems and for retrofitting existing production lines.

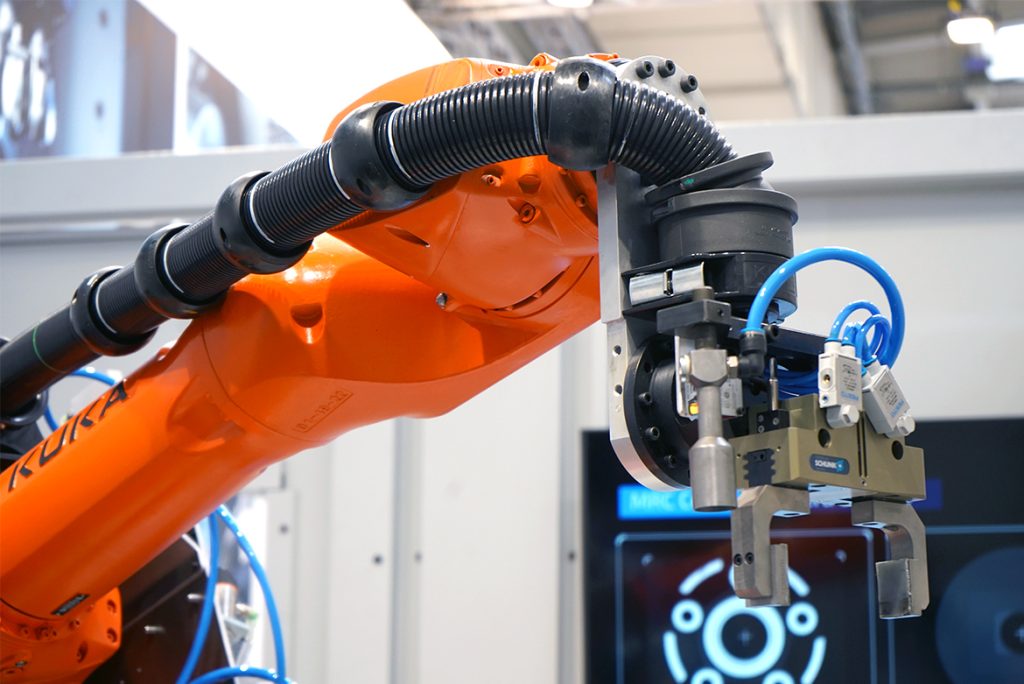

Industrial robots within the MRC robot cell during automated workpiece handling. Designed for stable processes and flexible automation in production.

Use cases: From bin-picking to palletizing

Flexibility was always at the forefront of the MRC’s design and development.

A typical example is the automated handling of differential housings. The components are removed from a workpiece pallet, gripped in the exact position and transferred to the shuttle of a machine tool. Thanks to the modular design, these processes can be transferred to other workpiece types without changing the basic structure of the robot cell. This results in a high level of investment security for changing product requirements.

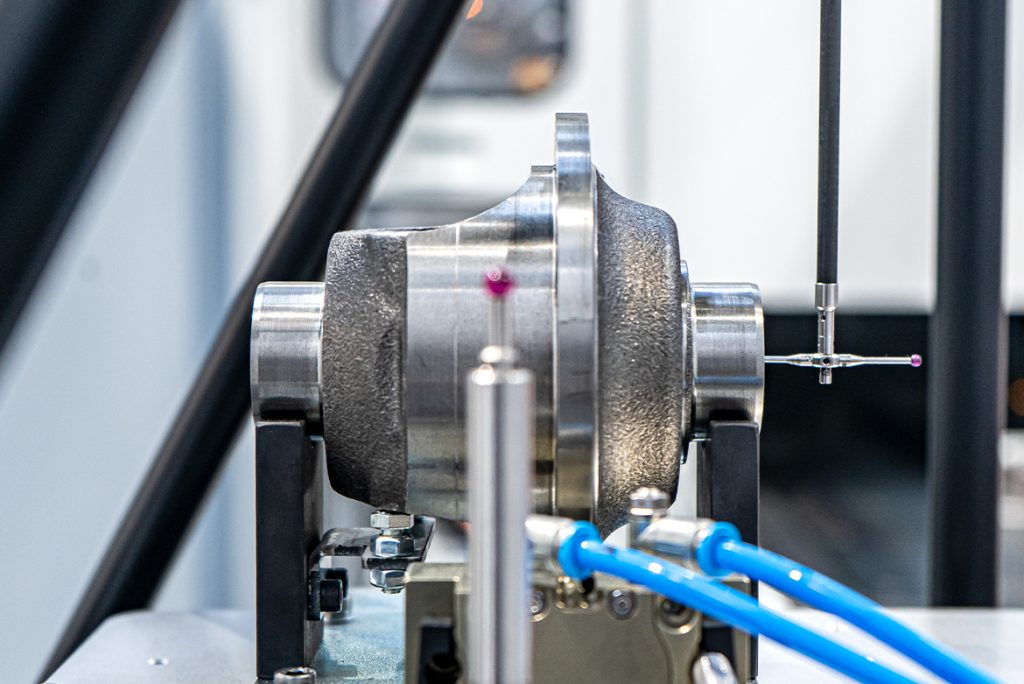

Workpiece measurment within the MRC robot cell with tactile measuring technology. Additional functions such as measuring can be integrated directly into the cell.

Standardized gripper and flange concept

Engineering effort is a key factor for economical automation. MRC relies on a universal flange system that can accommodate different gripper modules. Pneumatic, centric or parallel grippers can be mounted in different sizes.

The advantage of this concept is the reduction of project-specific special solutions. In many cases, customization is limited to the gripper jaws, while the flange, gripper module and interfaces remain unchanged. This simplifies the design while also reducing complexity in servicing and spare parts management.

Universal gripper and flange concept of the MRC robot cell for automated workpiece handling. Designed for different gripper modules and reduced engineering effort.

Software functions for reproducible processes

In addition to the mechanical design, software and operability play a central role in automation. The MRC has integrated functions for palletizing and position management. After measuring a reference base once, all gripping and depositing points are calculated automatically.

Manual teaching of individual positions is largely eliminated. Changes to pallet layouts or workpiece arrangements can be implemented within the software without having to fundamentally adapt the robot programs. This increases process reliability and reduces changeover times.

Benefits for users in automated production

The MRC is not an isolated automation module, but a flexible building block for integrated production concepts. Users benefit in particular from

- short project duration due to high standardization

- High flexibility in feeding and workpiece concepts

- standardized interfaces and gripper systems

- high process stability

- Fast integration into existing production lines

The MRC thus addresses the central requirements of modern automation in series and variant production and offers a technically clean solution for efficient workpiece handling.