Today we talk to Syl Kastrati, responsible for development at EMAG, about the new diagnostic tool EDNA Health Inspect, which has been specially developed for VL (Single/Duo), VSC (Single/Duo) and VT.

Mr. Kastrati, can you start by explaining to us what exactly EDNA Health Inspect is and what goals you are pursuing with this product?

With pleasure. EDNA Health Inspect is an advanced diagnostic and analysis tool that aims to efficiently and accurately assess the health of machine main axes and main spindles. Our goal was to develop an automated solution that would provide both our service technicians and our customers with a reliable foundation for assessing machine health, while at the same time significantly improving previous diagnostic procedures.

A service technician uses EDNA Health Inspect on a VL lathe while the analysis results are displayed on a laptop.

How does EDNA Health Inspect differ from previous tools such as Fingerprint and EDNA Health Check?

The differences are extensive automation and the extended diagnostic options. It is a further development of our previous systems – the manual Fingerprint and EDNA Health Check. While Fingerprint and EDNA Health Check have already provided good service, EDNA Health Inspect offers a more in-depth analysis based on new measurement techniques and high-resolution sensor technology. We have redesigned the tool from the ground up to create a more precise solution that delivers fast and reliable results. In addition, the system has been optimized specifically for VL (single/duo), VSC (single/duo) and VT machines.

What specific health conditions can be analyzed with EDNA Health Inspect?

EDNA Health Inspect examines several key conditions, including stiffness, running behavior, geometry and weight balance. Each of these conditions gives us important information about the condition of the machine axles. For example, the system checks the stiffness to detect wear or jamming, and checks the geometry to detect assembly errors or crash damage. Certain measured values help to create precise diagnoses. In the case of main spindles, possible imbalances or rolling bearing damage can be detected.

You mentioned that EDNA Health Inspect uses new measurement techniques. Can you tell us more about this?

Of course. For EDNA Health Inspect, we have integrated new measurement techniques and high-resolution sensor technology that go far beyond what was previously possible. In addition to the vibration sensors, we use control data, such as speed and current values, which enable us to collect more detailed information and thus carry out more precise analyses. This extension opens up new possibilities for detecting early signs of damage – even those that were previously difficult to detect.

How does the traffic light system work within EDNA Health Inspect and how does it help users?

The traffic light system is a simple but effective method of recognizing the current condition of the machine axles at a glance. It displays the diagnostic status in the form of traffic light colors: Green means that everything is OK, yellow indicates potential problems that should be monitored and red signals an urgent need for action. This system helps our service technicians and customers react quickly and efficiently to potential problems.

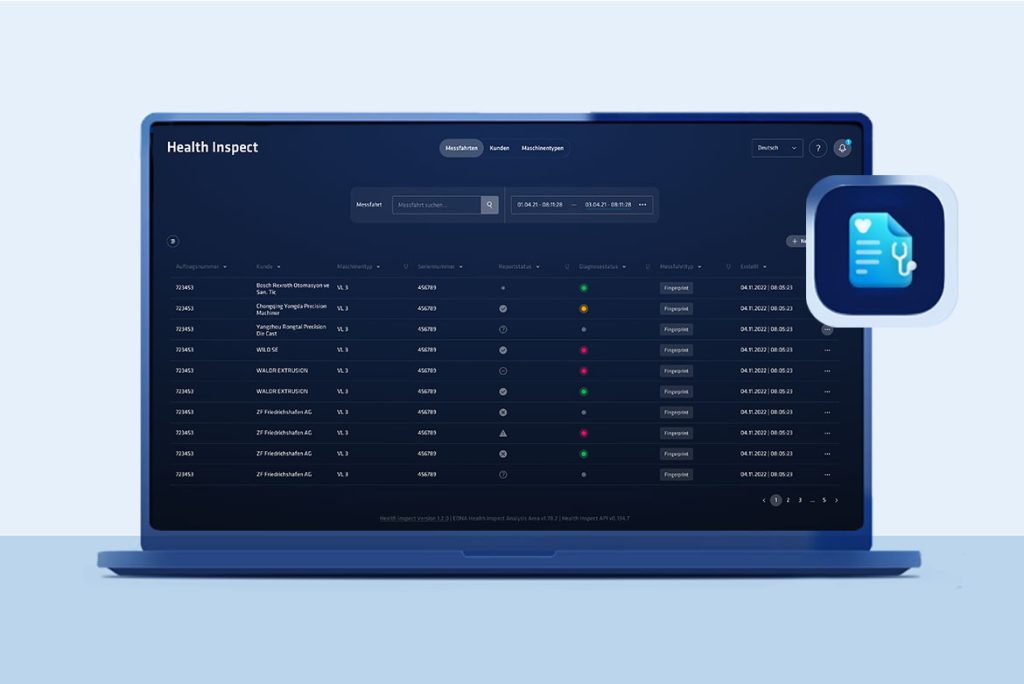

A screen shows EDNA Health Inspect’s traffic light system with green, yellow and red to indicate the status of the machine axes.

How are the analysis results presented and what information does the customer receive?

The results are summarized in a detailed report. This contains an overview of the machine axes/main spindles, the identified indicators, the interpretation of the data and specific recommendations for action. This information is reproducible and provides the customer with a clear basis for initiating the necessary maintenance or repair measures. Both our customers and our service technicians particularly appreciate the fact that this process is fully automated and no manual reworking is required.

What role does the experience of EMAG service technicians play in EDNA Health Inspect?

The expertise of our service technicians is an integral part of EDNA Health Inspect. We have incorporated their decades of experience into the development of the tool to ensure that the diagnoses are not only based on pure measurement data, but also on a deep understanding of the machines and their specific requirements. This knowledge enables us to provide precise recommendations for action that help our customers to extend the service life of their machines and minimize unplanned downtime.

A technician discusses the report based on the results of the EDNA Health Inspect system directly with the customer at a machine.

What are the future developments for EDNA Health Inspect? Are there already plans to expand the tool?

Yes, absolutely. We are already working on integrating additional functions. We are planning to further develop the tool so that it can also cover grinding/milling spindles in the future. Our aim is to continuously improve and develop EDNA Health Inspect to meet the changing requirements of our customers. We are also considering a customer portal with additional functions. It should then be possible to view the condition of both connected and non-connected machines in one central location.

Thank you for these detailed insights into EDNA Health Inspect.

With pleasure. We are convinced that EDNA Health Inspect represents a significant advance in machine diagnostics and look forward to developing and improving it further.