EMAG is known for its wide range of manufacturing technologies. At the same time, more turnkey manufacturing systems are now possible thanks to the design and development of automated solutions. Examples include palletizing or stacking cells with integrated robots, such as the recently introduced CRC stacking cell, the MRC bin-picking automation for bulk goods, the SCS 4 basket stacking cell and many more. We conducted an interview with Johannes Mauz, Head of Engineering Automation & Robotics at EMAG, about the possibilities that EMAG offers in the field of automation.

Mr. Mauz, what would you say distinguishes EMAG in general and in the field of automation in particular?

EMAG is the competent partner for the supply of high-quality, cross-technology manufacturing systems. We have many years of experience in the design and implementation of customized complete solutions with varying degrees of automation for our customers.

With our wide range of production technologies, we can develop individual solutions for every customer. What is often forgotten: Behind every successful production system is an equally successful automation system for parts handling. And it is precisely in this area that there have been numerous innovations in recent years. The EMAG bin-picking system, the EMAG stacking cell series, modular robot cells and also our already proven gantry loaders are all examples. In my opinion, the fact that we offer this entire spectrum from a single source is something special and also brings numerous advantages for the customer.

What are the specific advantages?

Thanks to the numerous manufacturing systems that EMAG has already successfully planned and implemented, we have very broad and valuable know-how. Nevertheless, every link-up is a new challenge and the more “unknowns” you have to integrate into such a system, the more complex the implementation becomes. If we can reduce this complexity by incorporating our own tried-and-tested solutions, the project planning is simplified considerably. We have less work at the interfaces, for example, as everything is already coordinated.

This also reduces the project planning effort for our customers if they can obtain machining and component handling from a single source. In addition, we are no longer so dependent on external supply chains. This is an aspect that has become much more important in recent years. Another advantage that should not be underestimated is CE conformity for the system network. This legally prescribed conformity procedure is significantly simplified the fewer partners and suppliers are involved. But there is another important advantage when our customers’ production system is supplied from a single source: Service and servicing are handled by EMAG specialists in a timely and professional manner. All this ultimately leads to a reduction in project planning and construction time.

How did the development of the portal system come about?

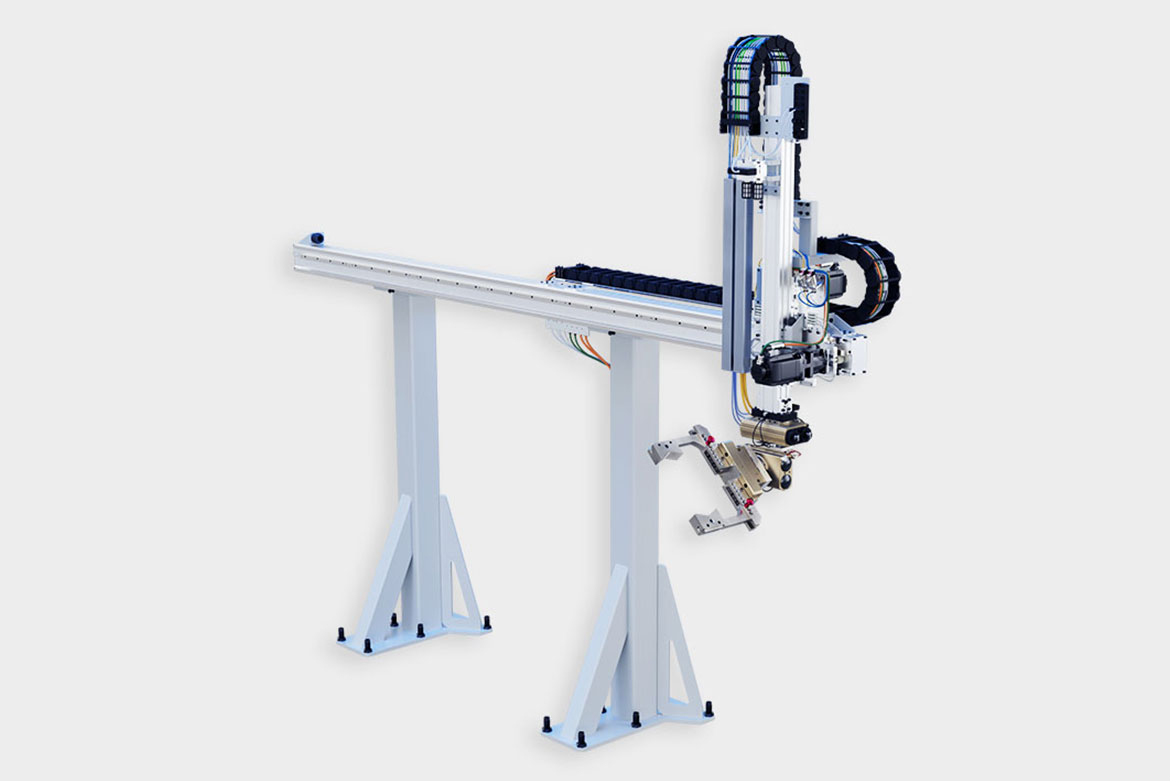

First of all, I have to say that portals are nothing new for EMAG. We have already implemented many projects with portals – both with third-party systems and increasingly with our own designs and developments. Over time, these have resulted in a proven “modular design.” With the LP 40 and LP 150, we have two sizes that have established themselves as standard and for which we also offer an extensive catalog of accessories and extensions. This ranges from pneumatic and electric grippers to integrated swivel units and a second carriage, which in turn can be operated either coupled as a tandem or completely independently if, for example, short cycle times are required. We now offer this solution to our customers as a further automation product, similar to our SCS stacking cells.

The LP 40 and LP 150 gantries are versatile automation solutions.

How does the portal system integrate into EMAG’s automation portfolio?

If you look at the material flow from the perspective of an automation specialist, we have our SCS stacking cells and bin-picking automation for feeding and removing components. Workpiece handling is then often carried out by robots due to their high flexibility and free programmability. However, if the layout requires greater distances to be covered, the flexibility of the robot is not absolutely necessary or the machine can simply be loaded more skillfully from above, the advantages of a gantry loader outweigh the disadvantages. In this context, our gantries integrate perfectly into our portfolio. What’s more, our automation systems can also be optimally combined with each other. By standardizing the interfaces, different automation solutions can be connected with each other. For example, we recently combined our gantry with the basket stacking cell from the SCS series; however, combinations with other systems from EMAG are also possible at any time. To make a long story short, with our gantries, we are even more broadly positioned in the field of automation and close the last gaps. This enables us to offer complete systems from a single source with all the advantages I have already mentioned. That is a strong argument in favor of EMAG.

Mr. Mauz, thank you for the interview.