EWS Weigele is known for its precision tool holders. What is less well known is the company’s technical standards and vertical manufacutring range – including the hard machining of its own bevel and toothed gears. A modernized VSC 400 DDS from EMAG plays a key role here. In this interview, plant manager Christian Schurr explains why the retrofit of this machine was a decisive step for EWS – technically, organizationally and strategically.

Retrofit

Modern production systems are a key factor for the competitiveness of manufacturing companies. For high-quality cylindrical grinding machines, a comprehensive modernization of existing systems can be an economically interesting alternative to purchasing new equipment. CNC-Technik Weiss GmbH, part of the EMAG Group since 2019, specializes in retrofitting Karstens cylindrical grinding machines. The Neckartailfingen–based company has decades of experience in overhauling and modernizing these precision machines. In an interview with Andreas Holstein, Plant Manager at EMAG Weiss, we were able to talk about the technical possibilities and economic aspects of retrofitting.

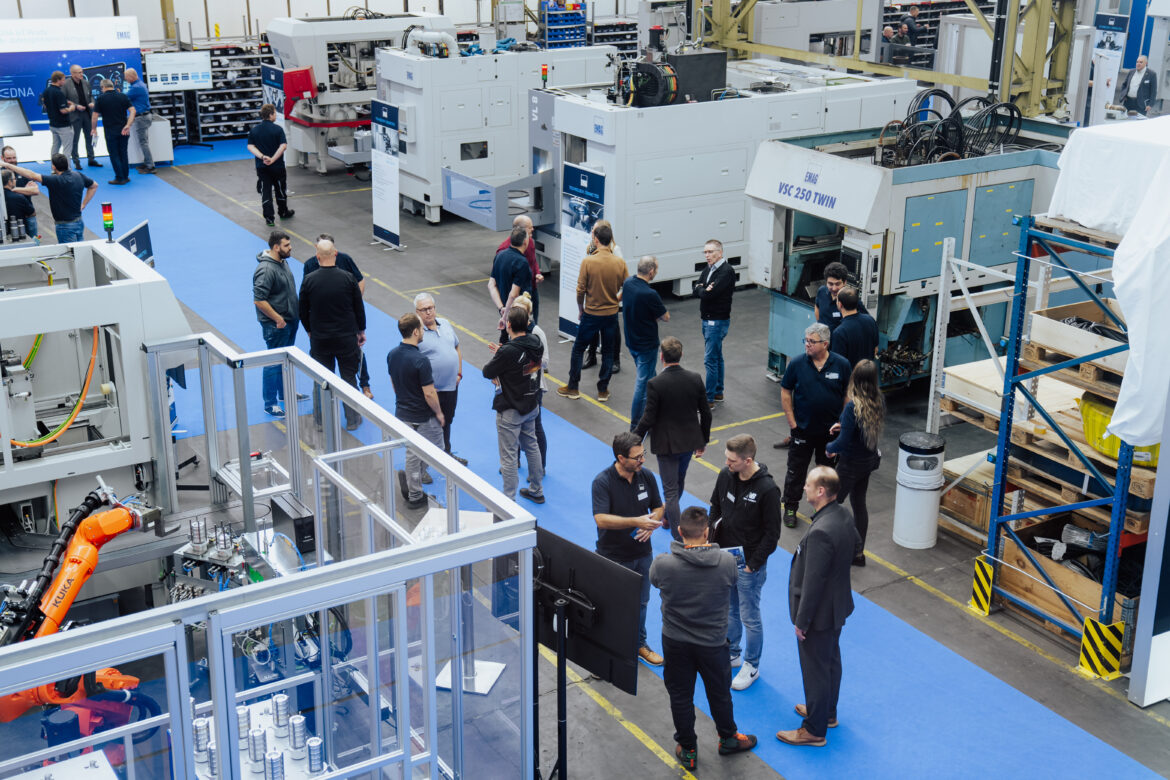

During the Open House Retrofit at the Eislingen plant, EMAG presented the future of industrial machine modernization. Visitors had the opportunity to experience the latest technologies and retrofit solutions at first hand.

What does retrofit do? The short answer – many things are possible. Depending on the customer’s wishes, the retrofitted machine not only has new components, but it is also equipped with new automation or additional tool technology. A turning machine, for example, becomes a turning-grinding center. Here we present just two examples among many possible scenarios.