The manufacturing industry faces the challenge of using production space more efficiently while also reducing process times. When machining flange parts, such as differential housings, several separate machining stations are required in conventional production. The VT 200 with counter spindle option shows how modern turning machines can address these challenges through process integration.

lathe

The machining of thin-walled workpieces is a complex task in manufacturing technology. Hardened rings and gears in particular exhibit considerable shape deviations after heat treatment. These components typically have elliptical, potato-shaped or triangular contours instead of the required circular shape. During subsequent lathe machining, conventional clamping systems often fail to achieve the required roundness tolerances.

The central challenge lies both in the deviation of the clamping diameter and in the interaction between workholding technology and cutting forces. While traditional diaphragm chucks, collet chucks or centering and face chucks can guarantee a mechanical fixation, out-of-round workpieces inevitably deform, leaving free arc segments between the clamping points. At these points, the lathe tool presses the thin-walled component outwards, which leads to additional shape deviations after spring-back. Even with optimized workholding technology, conventional processes often reach their limit at roundness values of 20 to 30 µm.

Turning balls, especially in safety-critical areas such as the automotive industry, places the highest demands on precision, repeatability and cycle time. Components such as ball pins in ball joints play a central role in steering and chassis. Their production requires state-of-the-art turning technology – especially when it comes to large quantities and economical processes.

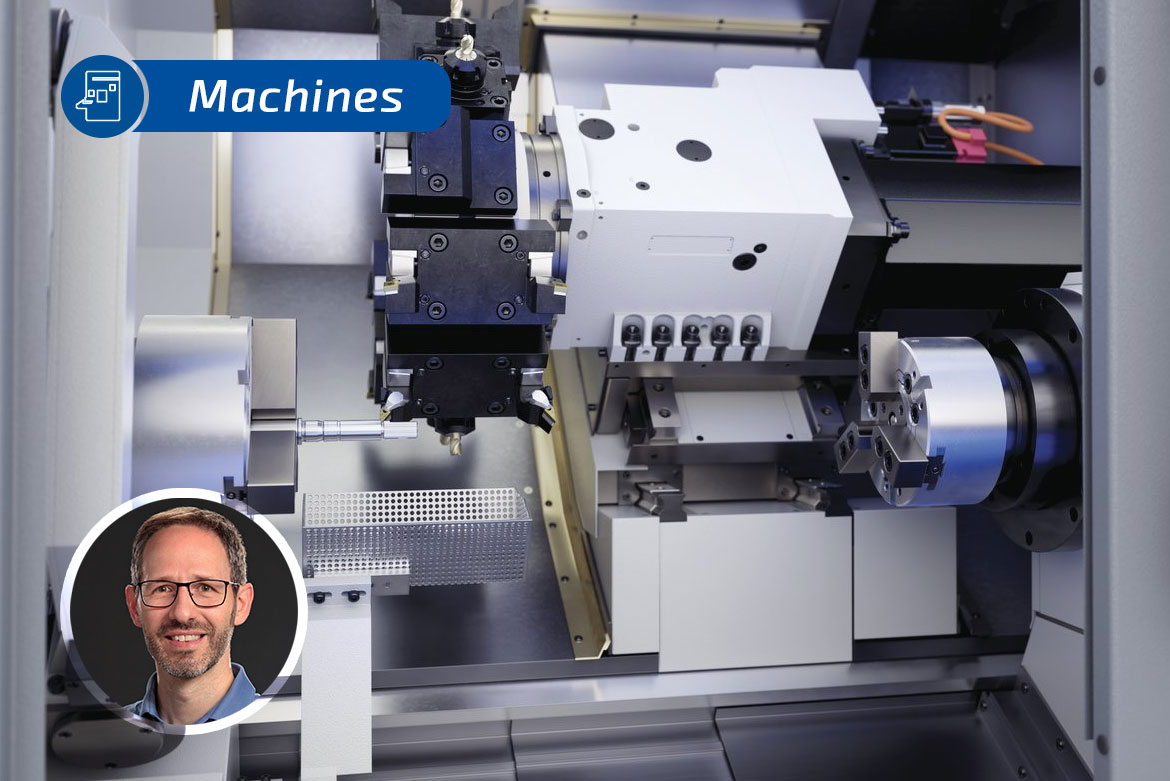

The requirements for CNC lathes are clearly defined: maximum process reliability, high machining precision, flexible application options and easy integration into automated production lines. A well-thought-out machine concept is particularly important for workpieces that require machining on both sides as well as additional milling or drilling. The HSC 1 from EMAG has precisely these aspects in mind. In this interview, Peter Gröner, Product Manager of the Turning Business Unit at EMAG, explains the technical features, the range of applications and the design considerations behind this machine.