The machining of thin-walled workpieces is a complex task in manufacturing technology. Hardened rings and gears in particular exhibit considerable shape deviations after heat treatment. These components typically have elliptical, potato-shaped or triangular contours instead of the required circular shape. During subsequent lathe machining, conventional clamping systems often fail to achieve the required roundness tolerances.

The central challenge lies both in the deviation of the clamping diameter and in the interaction between workholding technology and cutting forces. While traditional diaphragm chucks, collet chucks or centering and face chucks can guarantee a mechanical fixation, out-of-round workpieces inevitably deform, leaving free arc segments between the clamping points. At these points, the lathe tool presses the thin-walled component outwards, which leads to additional shape deviations after spring-back. Even with optimized workholding technology, conventional processes often reach their limit at roundness values of 20 to 30 µm.

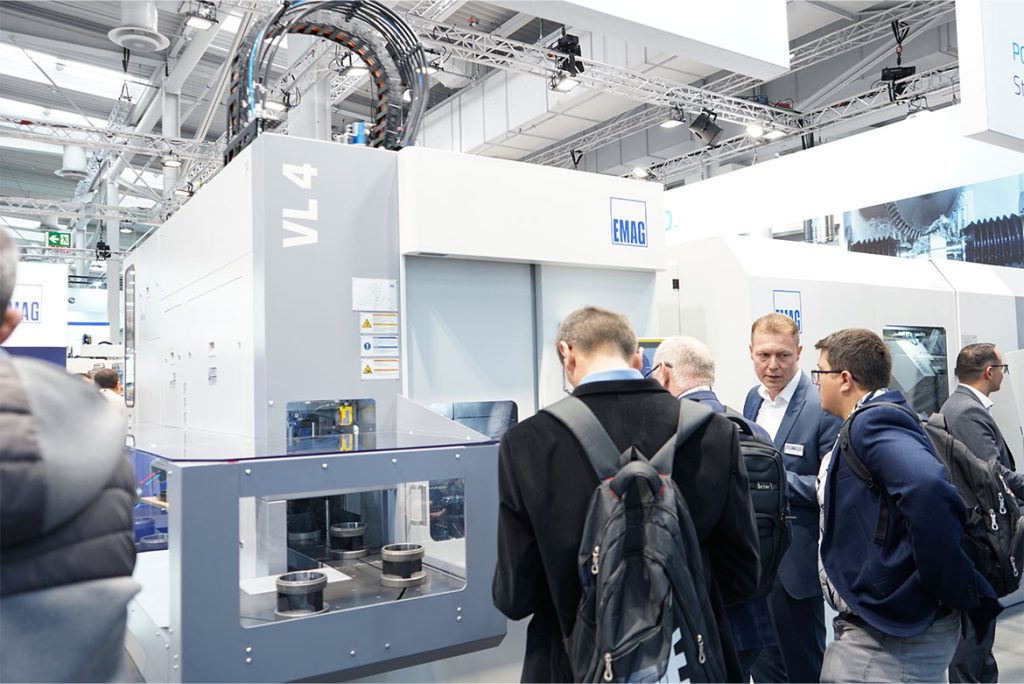

The VL 4 as a precision platform

The VL 4 lathe forms the ideal basis for the use of such high-precision clamping systems. The machine is part of EMAG’s modular VL series and is designed for vertical machining – a key advantage when handling sensitive, thin-walled components.

With its integrated pick-up automation concept, the VL4 ensures a fully automatic workpiece flow: Loading and unloading take place directly via the main spindle, minimizing non-productive times.

At the EMO 2025 trade fair, trade visitors can find out more about the EMAG VL 4 turning machine with integrated STERMAN PICEA clamping system for the precision machining of thin-walled workpieces.

Design and function of the STERMAN PICEA clamping system

The PICEA clamping system was developed by STERMAN specifically for the machining of out-of-round, thin-walled rings. It is based on a hybrid technology:

The PICEA clamping system on the EMAG VL 4 enables precision clamping of thin-walled workpieces through mechatronic centering and hydraulic face clamping.

- Electrical centering: three piezo elements measure and correct the position of the workpiece in the X and Y directions. They detect minimal deviations in the component shape (e.g. ellipses) and precisely shift the workpiece to its optimal center position.

- Hydraulic face clamping: Once centered, the workpiece is firmly secured by three hydraulic face clamping fingers. These ensure process reliability even in the event of an emergency failure.

The combination of both technologies creates a clamping system that enables micrometer-precise corrections. The piezo elements control both force and travel, allowing the clamping to be precisely adapted to the actual workpiece geometry.

Measuring process and adaptive positioning: How the clamping system actively corrects roundness

A key feature of the PICEA clamping system is the integrated measuring and correction process, which actively determines and compensates for the roundness of the workpiece – even before the actual machining on the lathe begins.

Multi-step measurement of the workpiece

After inserting the workpiece, a contact measurement is performed using piezo elements.

- The chuck scans the workpiece at three measuring points.

- The workpiece is then rotated by 120 degrees and the measurement is carried out again.

- This results in a total of six measuring points, which record the actual state of the workpiece contour.

This data forms the basis for the mathematical reconstruction of the ideal circular shape. A calculation formula is used to determine the perfect center point and the ideal circular position of the component from the six points – regardless of whether the real shape is elliptical or slightly deformed.

Adaptive readjustment of the workpiece position

Once the exact center point has been defined, the clamping system adaptively moves the workpiece in the X and Y directions to align it optimally to the machine axis.

This movement is performed by three individually controlled piezo elements, which can make minimal corrections in the range of a few nanometers to micrometers.

The process is fully automated:

- The VL 4 lathe gives the signal to start the measurement.

- The clamping system performs the measuring cycle and calculates the optimum center position.

- Adaptive positioning takes place directly in the clamping system – without external calculation processes or delays.

- After completion, the clamping system sends the “ready” signal to the control system, whereupon the machining process starts.

This adaptive readjustment ensures that even out-of-round or slightly deformed rings are clamped with perfect symmetry to the axis of rotation. As a result, the subsequent internal turning process takes place under optimum conditions – directly improving the achievable roundness.

Metrological precision in the nanometer range

The accuracy of this measuring process was tested in collaboration with Furtwangen University. Using a laser vibrometer, it was confirmed that the piezo elements can be controlled in the nanometer range – a precision that far exceeds the possibilities of conventional workholding technology.

This makes it possible to actively compensate for component deformations even before the turning process begins. This approach is a decisive advance, particularly for thin-walled, hardened rings, which often exhibit minimal distortion after hardening.

Clamping force control and process reliability

While electrical centering is handled via the piezo elements, hydraulic face clamping takes over the force-locking fixation of the workpiece.

This combination offers two advantages:

- Safety in an emergency – hydraulic systems can be reliably re-closed even if clamping force is lost.

- Stability during machining – the radial clamping remains constant without the component deforming during turning.

The piezos are force- and displacement-controlled. Even with a targeted increase in the clamping force, the dial gauge shows no significant deformation – an indication of the high rigidity and control quality of the system.

In the EMAG VL 4, the machined workpiece is finally measured to check the roundness achieved.

Measurement results from practice

The clamping system was tested over several months in batch production – including at KOEPFER, where components were previously machined using conventional mechanical clamping systems.

While roundnesses of 20-30 µm were achieved there, the results with the PICEA clamping system were between 5 and 11 µm – a significant improvement that had a direct impact on process reliability and the reject rate.

Another advantage: the more precise centering also stabilizes subsequent processes such as grinding or finishing, making them more efficient.

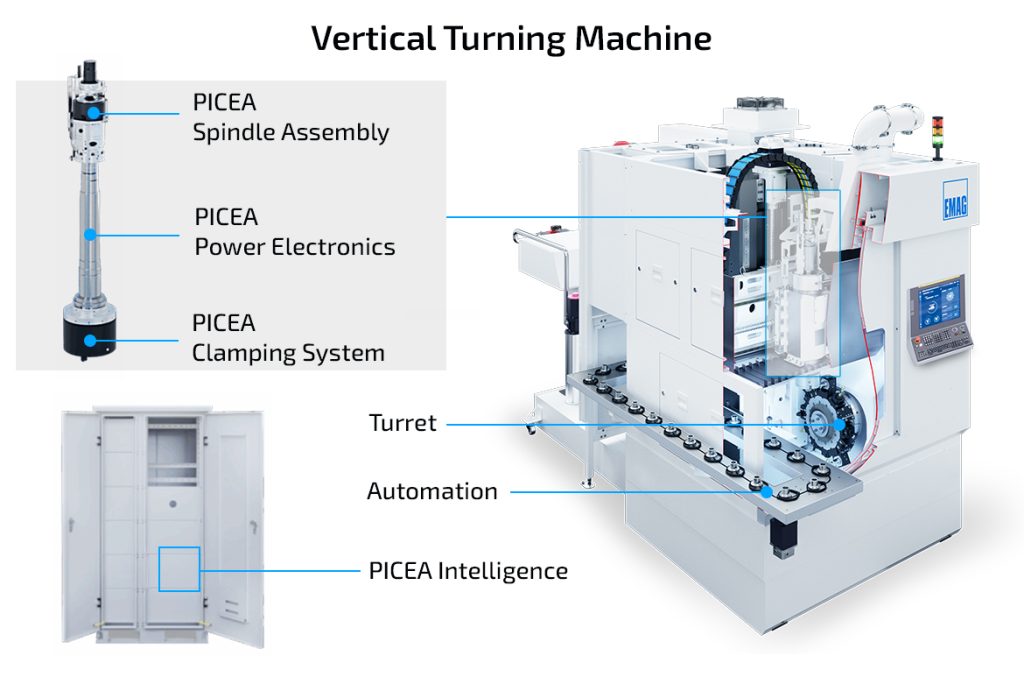

Illustration of the interaction of EMAG VL 4 lathe and PICEA clamping system

Intelligent workholding technology in detail

The PICEA clamping system contains an integrated microcontroller that evaluates the measurement data from the piezo elements in real time and controls the corrective movements directly. Each of the three clamping positions is controlled separately – similar to the axis control of a CNC control system.

This decentralized intelligence in the clamping system eliminates latency times and ensures precision synchronization with the control of the VL 4 lathe.

Energy and data are transmitted contactlessly via an inductive rotary transformer that supports up to 3,000 rpm. The system remains fully process-capable even at high motor speeds.

Advantages for production practice

Using the VL 4 with the PICEA clamping system offers a number of technical and economic advantages:

- Significantly improved roundness results for thin-walled rings

- Reduced reject rate and higher process reliability

- Can be retrofitted to existing machines (e.g. VSC series)

- Stable results even after hardening

- Quick integration thanks to simple electrical and hydraulic interfaces

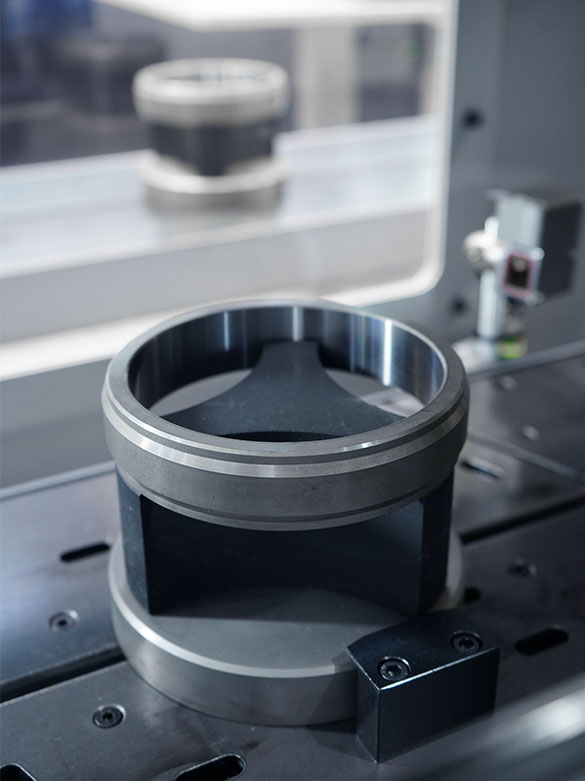

A thin-walled ring is ready after precision machining in the EMAG VL 4.

Combined with the robust machine base of the VL 4, this creates a precision manufacturing system ideal for components with high quality requirements – for example in transmission production or in the e-mobility sector.

The VL 4 lathe and the PICEA clamping system illustrates how mechatronic clamping systems are pushing the boundaries of precision machining. For manufacturers who want to machine thin-walled, sensitive workpieces with maximum accuracy, this system is a technically convincing solution: It is precise, retrofittable and economical.