The insertion of field rifling profiles into a barrel – such as those used in sporting rifles – is a very demanding task. The complex internal geometry is difficult to achieve using conventional cutting and forming tools and must be manufactured with extreme precision. While forming processes are often used, they require high capital investment and generate additional process costs. Electrochemical machining (ECM) from EMAG offers an alternative: a fast and effective process that delivers high-precision surfaces. In this interview, Daniel Plattner, Technical Sales Manager at EMAG ECM, discusses the possibilities of this innovative production method for rifling.

Why is the ECM process so interesting for manufacturers of sporting and hunting rifles?

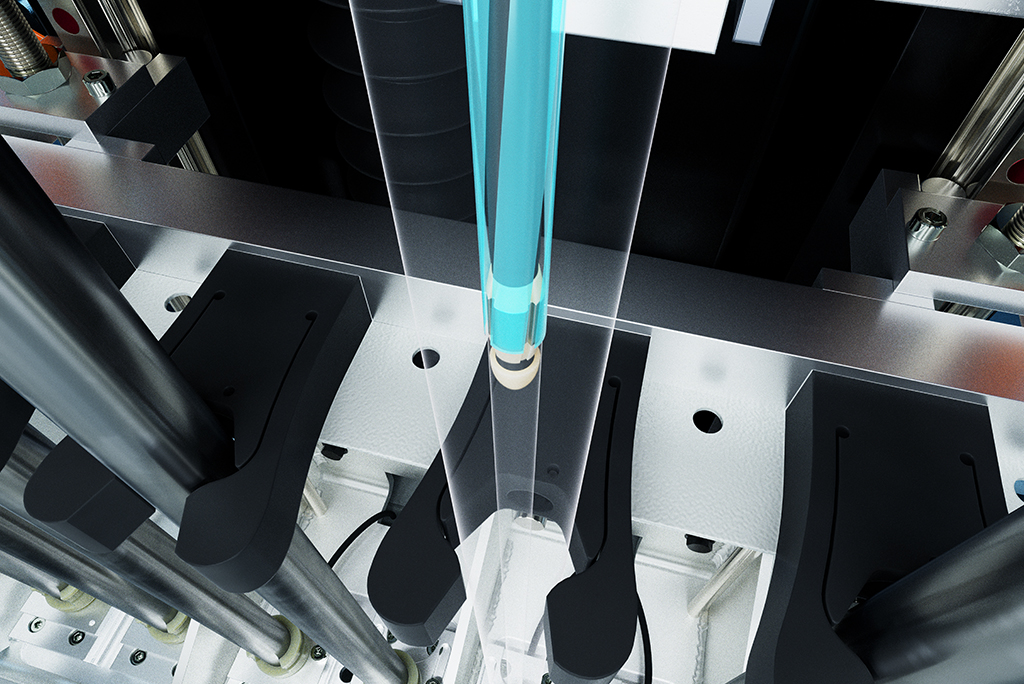

First, we need to say a few words about our process. ECM is particularly well suited for applications that require the production of high-precision geometries despite high material hardness. The basic principle is always the same – irrespective of the material: a direct current or pulse source polarizes the workpiece positively as the anode and the tool negatively as the cathode. An electrolyte solution flows between the two, and metal ions detach from the workpiece. There is no mechanical or thermal stress on the component. What’s more, the whole process also works with geometries that are difficult to access, such as the inside of a gun barrel.

The cathodes enter the tube blank and remove the excess material.

How does the ECM process for manufacturing field tension profiles work on your PI platform, and which geometries can be realized with it?

We have developed a universal and modular PI platform that uses a special rifling cathode to produce field rifling profiles. Different geometry requirements such as “polygon”, “progressive” or “standard” can be achieved with up to eight tool cathodes. The production process itself is quick: the operator places eight blanks in the workpiece holders. The eight cathode tips then move just above the blanks and remain there briefly until a trailing sealing unit surrounds them. The ECM- process begins, with the cathodes gradually moving deeper into the tube blank, removing the excess material.

What cycle times are possible?

This depends on the desired internal geometry and the length of the barrel. Let’s take the 420 millimeter barrel of a hunting rifle as an example. Here, the process only takes 297 seconds at a feed rate of 85 millimeters per minute. With parallel machining of eight components as mentioned above, a cycle time (process time) per component of 37 seconds can be achieved. This results in around 97 runs per hour. These are very good values compared to hammering or drawing, which is often used here. Our process is more efficient, easier to operate, has lower capital investments and eliminates certain subsequent processes such as annealing. ECM offers the most flexible and cost-effective solution on the market for barrel production.

Special tool modules are available for different workpiece sizes.

What is your assessment in terms of process reliability?

It helps to compare ECM with hammering, which is ultimately a forming process. In hammering, the blank is first pre-drilled and honed on the inside. The machine then inserts an internal mandrel with a negative profile and the forging hammers machine the barrel from the outside until the profile is reproduced in the barrel. Of course, this also changes the external geometry of the barrel and the material structure, which in turn leads to a high reject rate in practice. Different materials and calibers are associated with high set-up costs. You do not have these problems at all with ECM rifling: The external geometry of the blank already corresponds to the later finished geometry, which benefits the overall process reliability. In addition, tool wear is very low and the cathodes can be produced in-house. This also ensures extreme repeat accuracy. The changeover times are very short!

What role does EMAG mechanical engineering play overall?

Our solution is based on the modular PI machine, which incorporates extensive EMAG expertise. Its proven basic structure is always the same, only the technology inside is adapted. This approach allows us to move quickly in design and development, and the customer ends up with a highly economical and tailor-made overall solution for the desired product portfolio.

How do you assess your market opportunities in general?

We believe that we are optimally positioned for the market. A whole series of machines are already in use in the USA and Europe at various well-known rifle and pistol manufacturers, and we continue to receive strong interest. The advantages of our technology – reliability, flexibility, repeatability, surface quality and low production costs – are becoming increasingly recognized on the market. Incidentally, we also have an application laboratory at our Heubach site. Here, customers can machine their components for the first time using the ECM process, determine cycle times and component tolerances and check reproducibility. So if you are not yet convinced, you can play it safe.