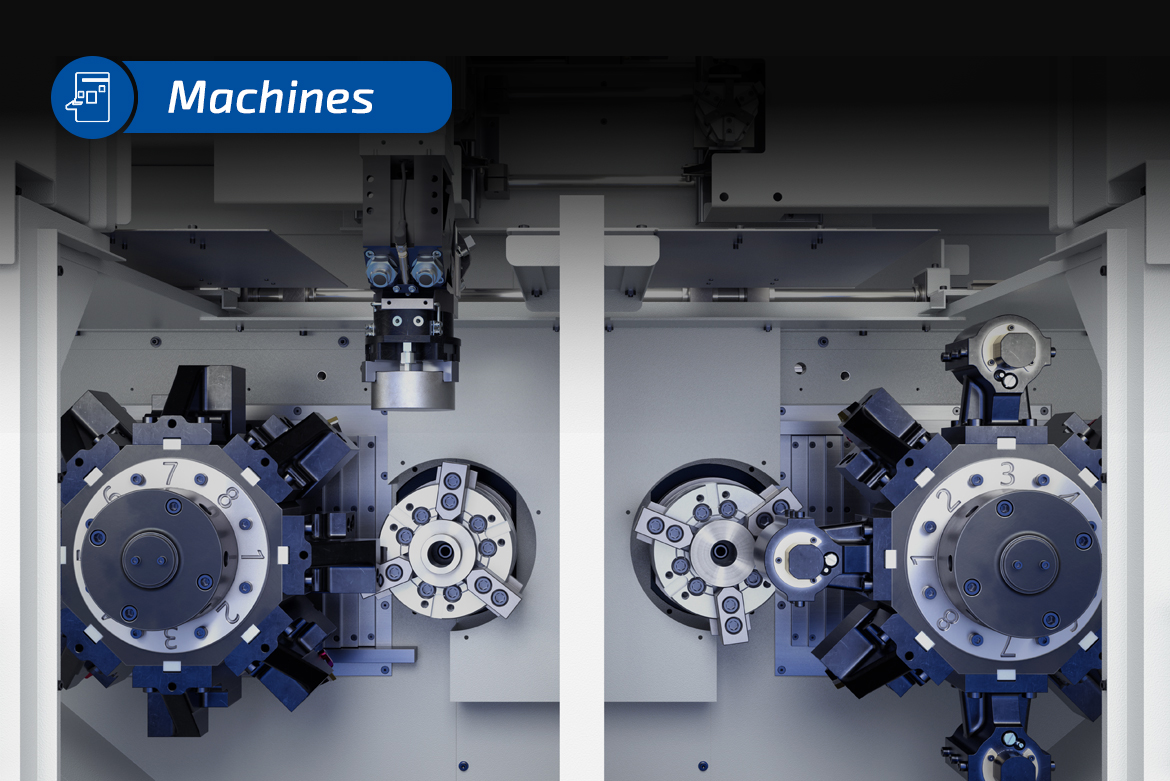

The automated production of turned parts in medium and large batch production requires CNC turning machines that combine productivity, process reliability and cost-effectiveness. The MSC 5 DUO from EMAG’s Classic series addresses these requirements with a machine configuration consistently designed for automation. As a fully automated CNC lathe with a double-spindle concept, the machine is positioned in the compact manufacturing cell segment for workpieces up to 120 mm in diameter and 85 mm in length.

CNC lathe

EMAG recently introduced the USC 850 CNC universal turning machine – a precision and powerful turning machine for large workpieces. In the following interview, Bernd Scheschy, Technical Sales in the Turning Business Unit, explains the technical features of this machine.

In the race to stay competitive, manufacturers are always searching for equipment that balances productivity, precision and affordability. EMAG’s Classic Machine series is designed to meet this challenge head-on. The machine front and center in this lineup, the MSC 5 DUO, exemplifies how “just enough” can be more than enough – especially when built on proven technology and smart engineering.

An interview with Peter Gröner, Product Manager Business Unit Turning at EMAG, about the new MSC 5 DUO turning machine and its answers to current challenges in machining production.

MR Components, a medium-sized company from Grigno, Italy, has significantly increased its production capacity and simultaneously improved quality by introducing intelligent automation with EMAG machines. The company, which specializes in the production of parts for differential and planetary gears, now produces around 80,000 components per month, with some of the machines running unmanned in the evenings. In conversation with Alessandro Reguzzo, owner and Managing Director of MR Components, we were able to find out more about the company’s production philosophy and design and development.