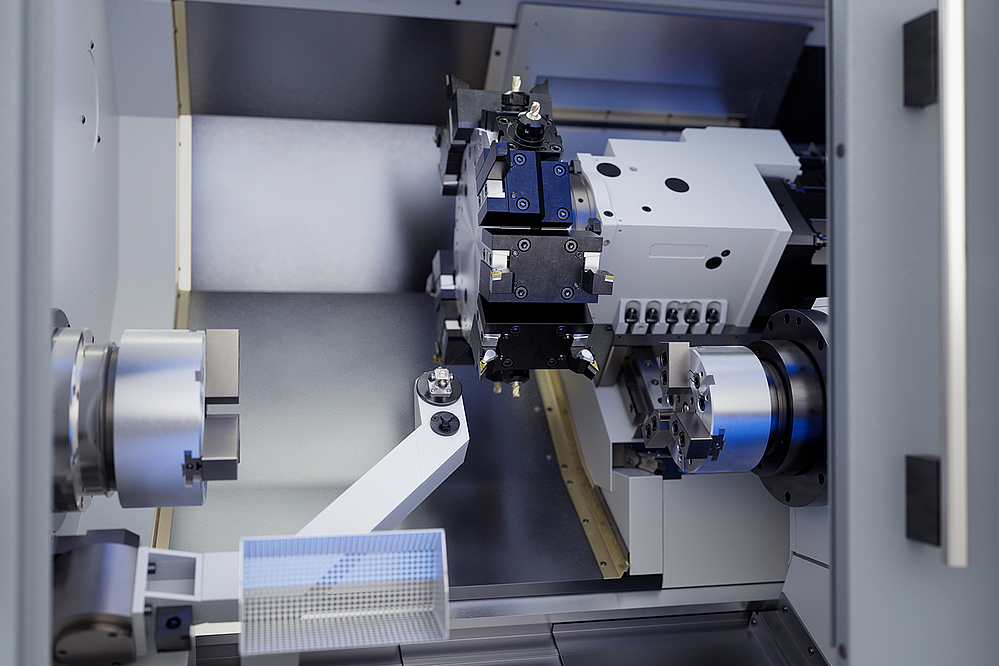

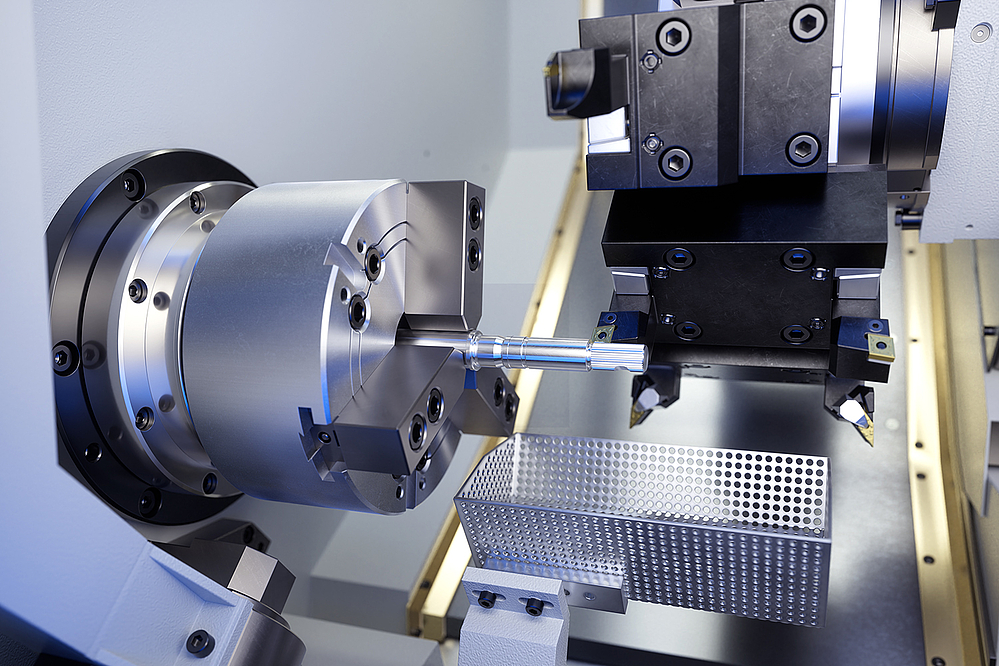

OP 10 / OP 20 带主轴和副主轴加工

主轴(A2-6,主轴通孔 Ø 63 毫米)和功能强大的副主轴(法兰直径 Ø 110 毫米)可实现工件两面的完整加工。自动传输提高了加工可靠性,减少了人工干预,是中型系列和复杂车削件的理想选择。

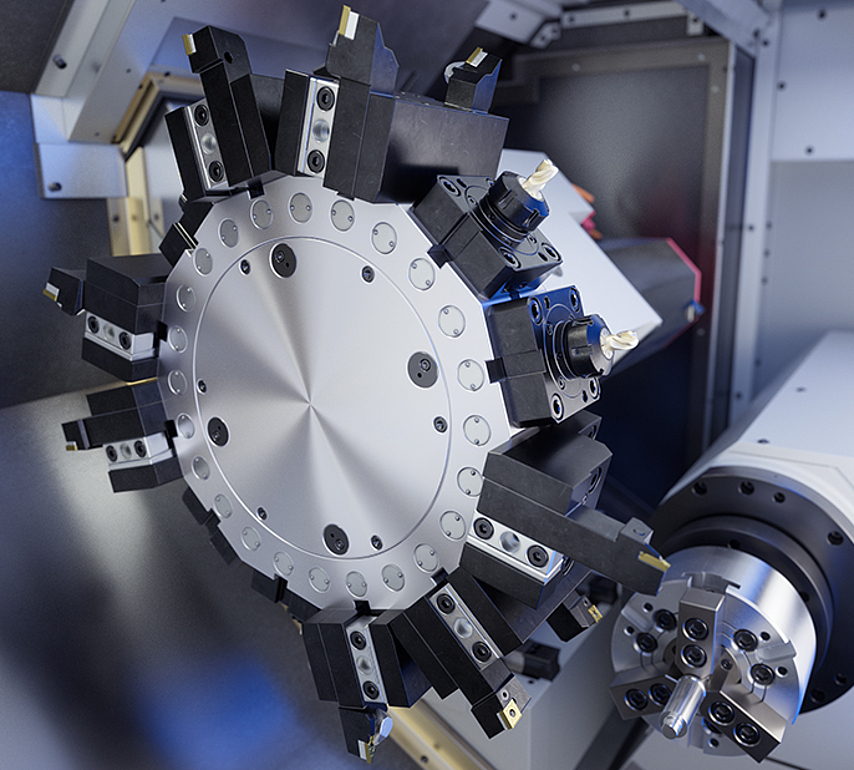

使用驱动刀具进行铣削操作

带有 12 个工位的刀塔(BMT-55)可完全配备驱动刀具。这些刀具的最大加工时间可达 5000 分钟-¹,可在车削过程中进行铣削加工,例如横向钻孔、键槽或螺纹铣削,而无需单独的机床。

全轴设备,包括 Y 轴

除了线性 X、Y 和 Z 轴外,HSC 1 的两个主轴上还装有 C 轴。行程为 ±50 毫米的真正 Y 轴大大扩展了加工范围:即使是偏离中心的轮廓也能经济地加工出来。

重型倾斜床身底座由优质铸铁制成,可确保低振动加工和最佳排屑效果。直线导轨和预紧滚珠丝杠确保了高定位精度的动态运动。

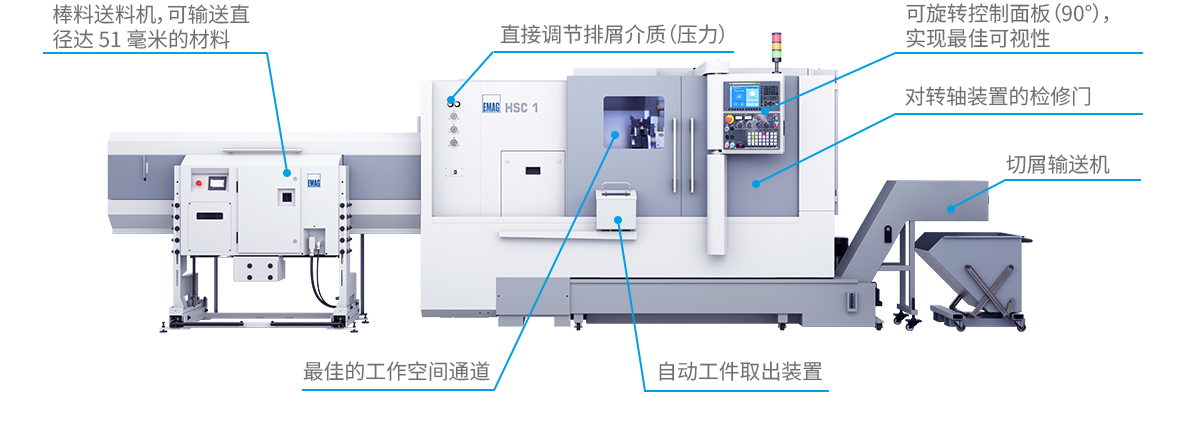

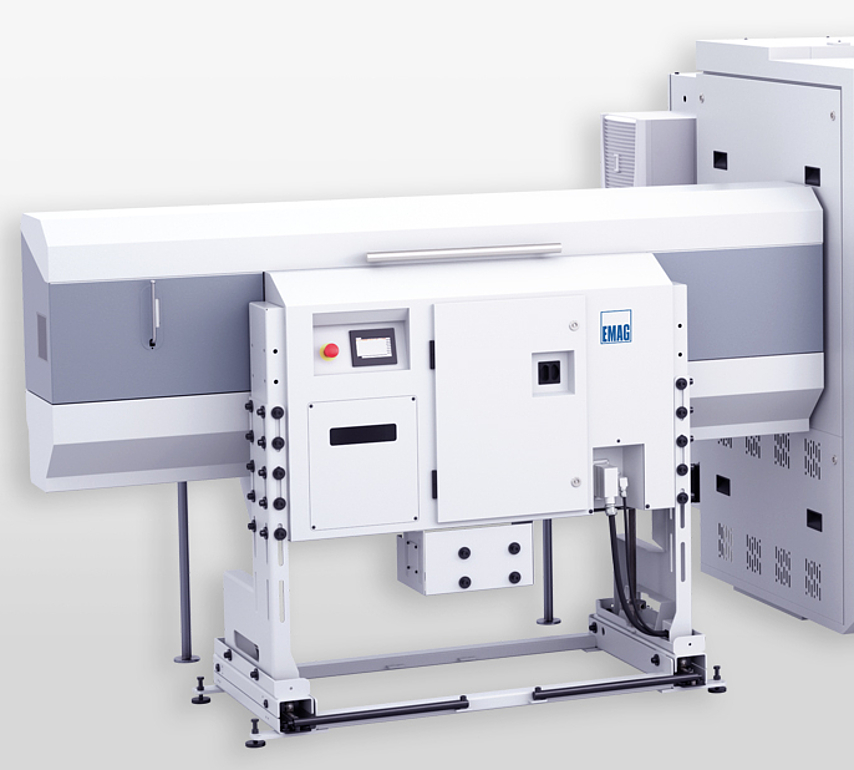

使用棒料装载机自动处理棒料

HSC 1 可以选配棒料送料机,用于批量生产圆形材料车削件。根据型号(液压或伺服控制)的不同,可以自动送入直径为 6 至 50 毫米的棒料。这样就可以在较长时间内实现无人操作,是大批量生产的理想选择,而且操作工作量极小。