使用 EDNA ONE 简化机床操作和设置

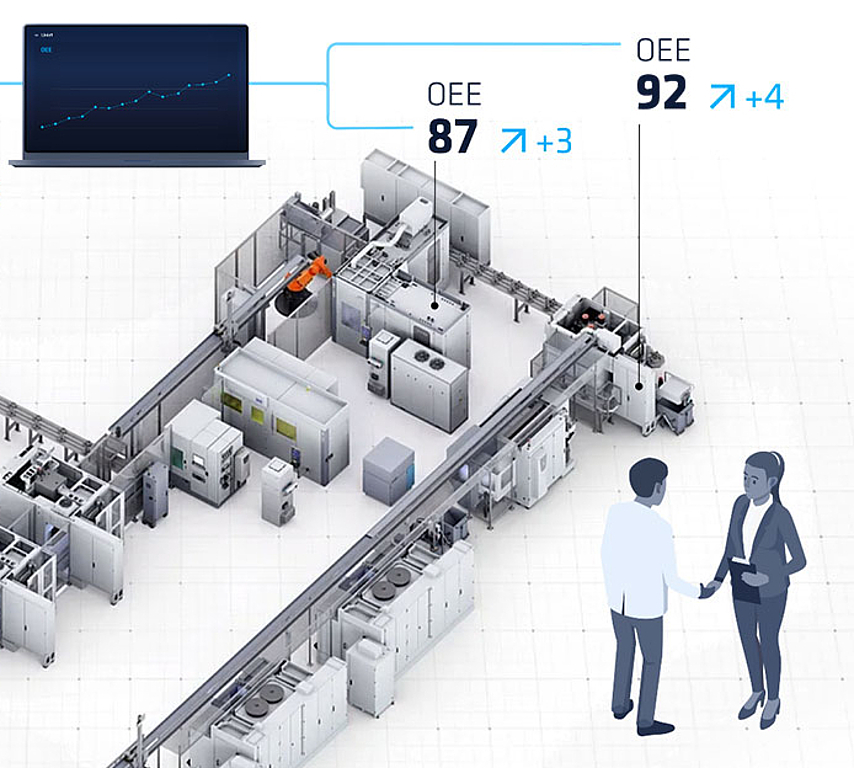

通过 EDNA ONE,您可以将生产转变为智能生产环境。智能机床技术可独立完成大量日常任务,大大减少了工作量和出错风险。操作员如释重负,可以集中精力完成要求更高的任务,而机床则基本独立工作,确保最高精度。

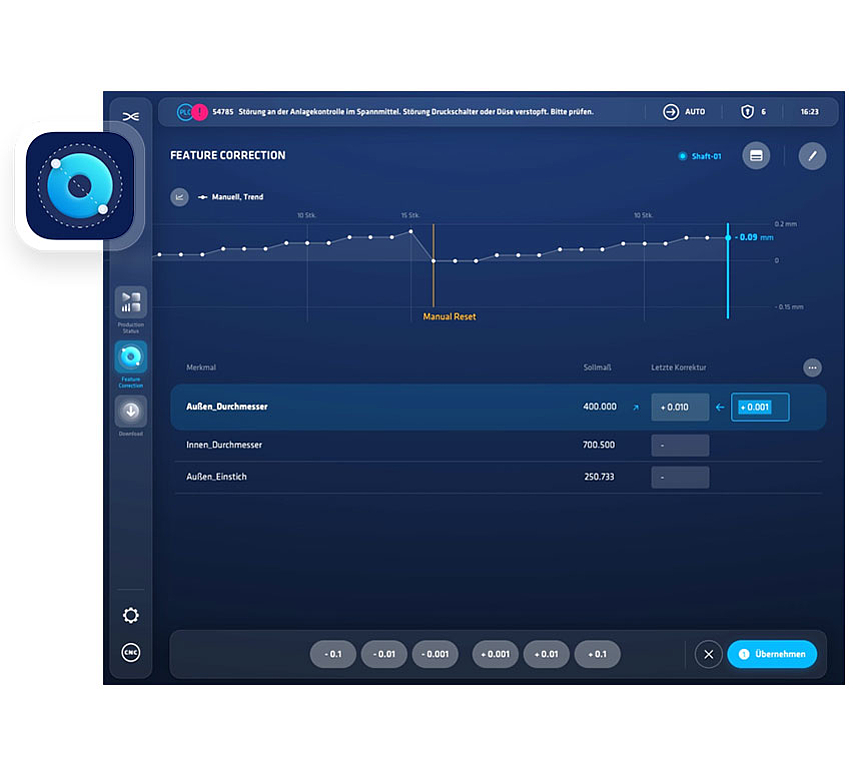

通过实时监控和分析过程数据进行优化

EDNA ONE 提供功能强大的工具,用于持续监控和分析相关机床数据,如节拍时间和修正值的详细信息。通过实时分析,您可以立即识别偏差,主动做出反应,并有针对性地调整工艺。这样可以减少计划外停机时间,永久性地提高生产效率。

高性能刀具,实现最高生产质量:

- 基于需求的信息显示:操作员只能看到刀具状态、目标值或特定修正目标等相关信息。

- 直接在功能上实现趋势可视化:对历史校正数据进行图形化处理,以便在出现过程偏差时进行早期干预。

- 清晰的修正特征管理:图形编辑器简化了特征程序的创建、复制和分配。

- 直观的图形配置:通过对源变量和目标变量的直观可视化,可轻松设置校正过程。

- 可视化支持:将数字图纸直接集成到用户界面中,实现直观、无差错的操作。

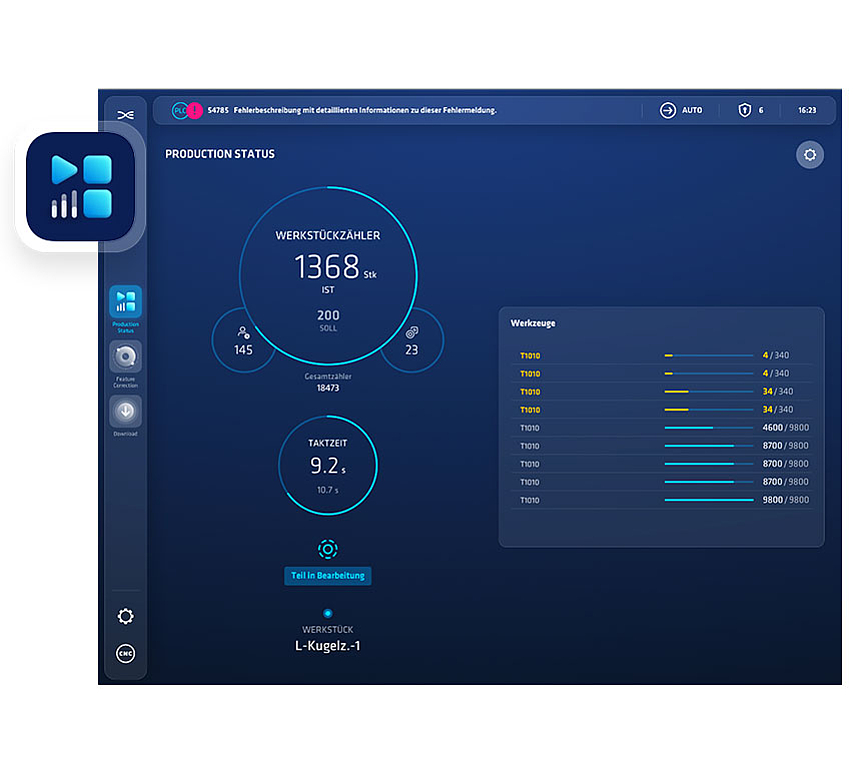

中央可视化系统实现全面生产控制:

- 全面的实时数据:数量、节拍时间和状态信息一目了然

- 刀具更换预测: 前瞻性地计划刀具更换,及时提供刀具,避免停机。

- 快速应对瓶颈:立即识别关键条件,积极控制生产,最大限度地提高效率。

高效换刀:优化刀具寿命规划

通过换刀预测功能,您可以优化生产系统的整个换刀过程。精确的刀具剩余寿命显示让您受益匪浅,从而大大缩短了调试时间。

优化生产计划,减少停机时间:

- 精确预测刀具剩余寿命

- 及时规划和准备刀具更换

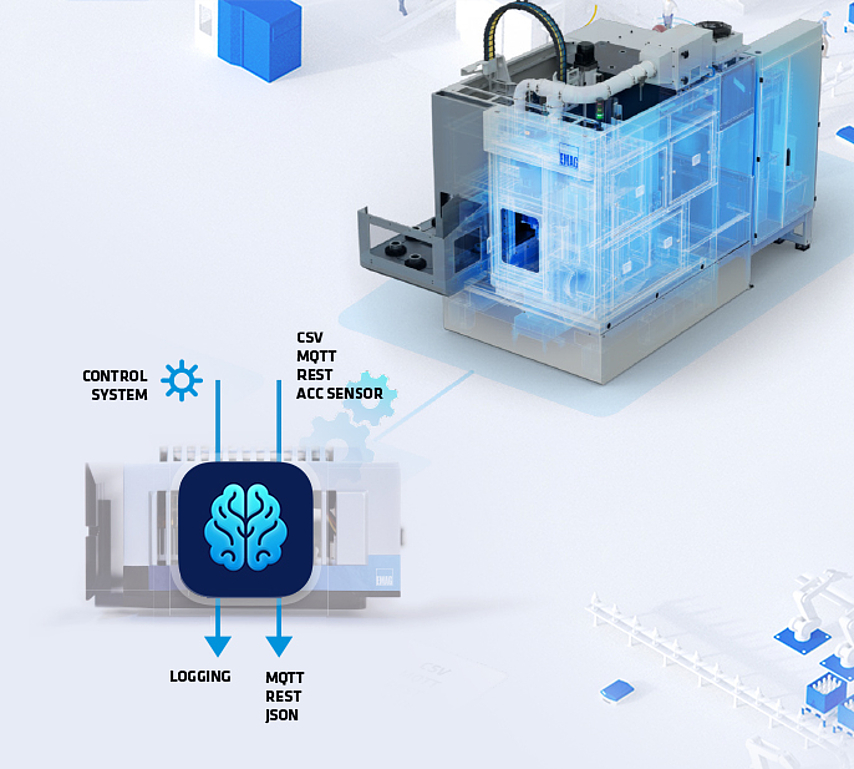

利用 EDNA Cortex 进行状态监测,可通过分析过程参数采取行动。

例如,在发生超限/欠载时,可以发出警告,以便立即采取措施。状态监测可为机床提供额外保护,并提高生产质量

联系物联网

您有任何问题或需要有关该机床的详细资料吗?请联系我们!

iot@emag.com