06/30/2025 - Oliver Hagenlocher - 新闻中心

埃马克的 VLC 450 DG: 磨削涂覆后的汽车制动盘

未来的刹车盘是带涂层的,只有这样才能达到欧 7 标准中颗粒物限制。还能更严格的制动表面防止腐蚀和磨损。但是,哪种加工工艺能保证大批量生产时可靠地保证这种质量呢?埃马克基于 VLC 450 DG 机床以及激光涂覆和随后的双面表面磨削加工工艺相结合的出现,给出了完美的答案。后者是决定性的生产因素,因为涂层对磨削工艺的要求很高。VLC 450 DG 的具体特点是什么?

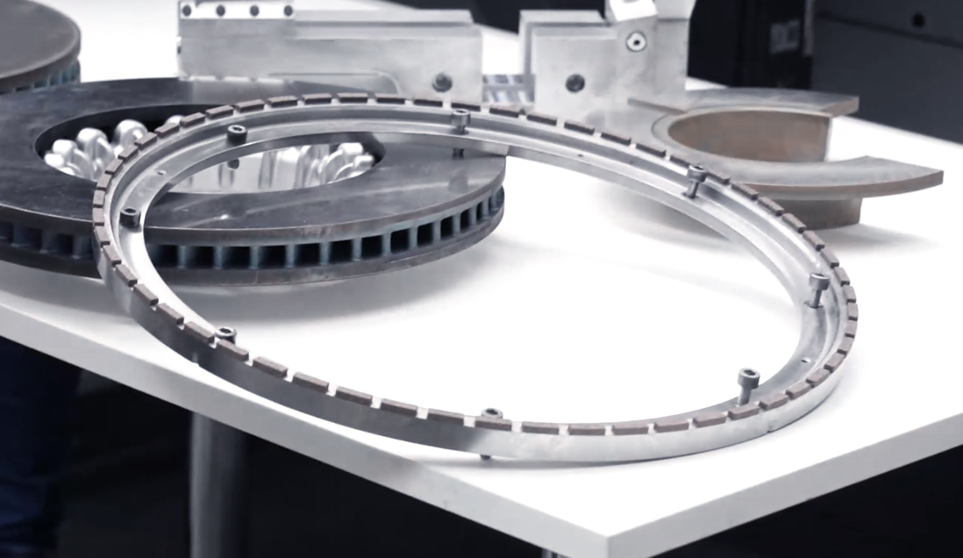

图片:

欧 7 标准即将出台,随之而来的是对轮胎和制动系统磨损的严格限制。允许从 2035 年起,只允许汽车每公里排放3毫克的颗粒物,这是一个根本性的降低,因为目前根据车辆的不同,这一数值高达 40 毫克!但如何在技术上实现这一目标呢? 在汽车行业的研发人员给出的答案。“用硬材料涂覆刹车盘”埃马克公司的激光涂覆技术提供了多种可能性:基体材料和硬质材料碳化物被送入激光工具并焊接到预热表面。这样,至少在所谓的双层系统中,首先是粘合层,然后是外层磨损保护层。也有开发人员采用单层解决方案,例如用于紧凑型车辆的后轴。

然而,一个显而易见的问题是:如何将这种方法整合到一个整体的大批量生产解决方案中 - 包括后续磨削工艺,它使刹车盘达到最终表面质量? “这个问题是我们的首要任务”,埃马克磨削技术负责人 Jannik Röttger 解释说。“我们的独特卖点在于,一方面,如果客户愿意,可以在埃马克机床上控制和影响磨削工艺和整个激光涂覆工艺。另一方面,我们从一开始就监控随后的磨削工艺。毕竟,磨削工艺和集中涂覆参数的配置方式使用于磨削的表面得到最短的磨削节拍和最小的砂轮损耗并得到最好的磨削精度,两种工艺之一的孤立解决方案会产生有问题的性能数据。”

完美的磨削工艺

VLC 450 DG 是埃马克专家为制动盘量身定制的特殊解决方案,其每个细节都是根据相应的涂层系统和所需的生产工艺而设计的磨床 – 展示了什么是真正意义上的机械工程。重点在是每种情况下,都采用双端面磨削,这是一种既高效又可靠的工艺。它可以在零件上形成十字交叉磨削纹路,展现出非常有利的摩擦学特性同时,交叉磨削还有助于直接进行质量控制,因为进出磨粒的轨迹可以确认所有轴角都已正确设置。

双端面磨削还具有其他工艺优势。相关的对称施力可实现最大的加工进给率。砂轮和制动盘之间的大表面接触确保了最佳零件支撑,从而保证制动盘的高质量,因为制动盘在轴向非常不稳定。使用的是含矿物油的水(非乳化液),其中的细小磨粒很容易被过滤掉。即在这方面,我们与切削液和过滤系统的制造商进行了密切合作。“顺便提一下,这也是 VLC 450 DG 立式布置给用户的好处带来,因为磨削污泥中含有高强度的磨削颗粒。如果采用水平刀具布置,导轨很快就会出现问题。我们的机床可以应对这一挑战” Jannik Röttger说。

总体而言,埃马克机床的整体理念设计是最大限度地提高生产率和耐用性,以满足批量生产的高要求。例如,全面的冷却概念确保了良好的热稳定性,Mineralit 床身最大限度地减少了振动,工作区外的机床穿梭料道为下游自动化系统提供了理想的接口。拾取主轴将工件从穿梭料道送入工作区,最大限度地缩短了屑到屑的时间。VLC 450 DG 的磨削刀具也为制动盘的加工设定了新标准:它被设计成一个可互换的圆环,重量不到 5 千克。因此,更换刀具的时间不到十分钟 - 非常短!总之,立式设计的工作区易于操作,安装极为方便。操作员可以轻松接触到所有更换部件。

整体观不可或缺

最后但并非最不重要的一点是,对涂覆制动盘整个工艺链有一个整体的认识,因为这两种工艺会对彼此产生决定性的影响。重要的是要知道,虽然激光涂覆总是能产生类似表面粗糙度(Rz高达 100 微米),但这种表面的强度取决涂覆系统而有很大差异。结果来看,单层和双层系统方式也不同的磨削:第一种方式可允许较高的切削速度,而第二种方式则要求电机特性具有较低的速度和同时较高的扭矩。换句话说,单层系统类似于淬火钢,而双层系统的摩擦层具有类似于硬质合金的切削性能。埃马克自己的磨削主轴可为这两种提供应用合适的性能参数,从而实现高效加工。

还有其他一些参数,例如磨料的选择,对磨削工艺的生产率至关重要。“机床制造商研发部门、砂轮制造商和磨料供应商之间的直接信息交流至关重要。只有不断交流知识,才能针对每种涂层规格共同开发出最佳砂轮。”Jannik Röttger 说道。

“总之,至关重要的是,磨削、涂层和激光专家要密切合作,并在此基础上制定最佳的整体解决方案,使涂层在制动系统中具有最佳性能,同时易于加工,”扬尼克-罗特格强调说。“我们为客户提供完整的机械工程和应用专业知识,包括原型设计,当然这也适用于埃马克只提供磨削技术。在任何情况下,VLC 450 DG 都专门为这一应用开发的机床,而同时还具有埃马克所有典型品质机械制造和数十年的丰富的经验。”

联系人