Exactly 1,223 innovations saw the light of day in the automotive industry last year—at least that’s according to a count conducted by the Center of Automotive Management and the consultancy firm PwC. About 27 percent of these innovations pertain to driver assistance and safety systems—one in five belongs to the field of engine construction. Considering the corresponding automotive production, one trend that has been going on for years still holds true: The pace of change is always increasing as the requirement for more flexible production continues to increase. It is important that new parts and components can be produced efficiently, and defect free using existing product solutions.

Manufacturing Systems

Electric power steering has become standard in the manufacturing of automobiles. The technology guarantees very precise steering support for every type of vehicle, high-end driving comfort, and lower energy consumption in the steering system, which has a positive effect on the car’s CO2 consumption.

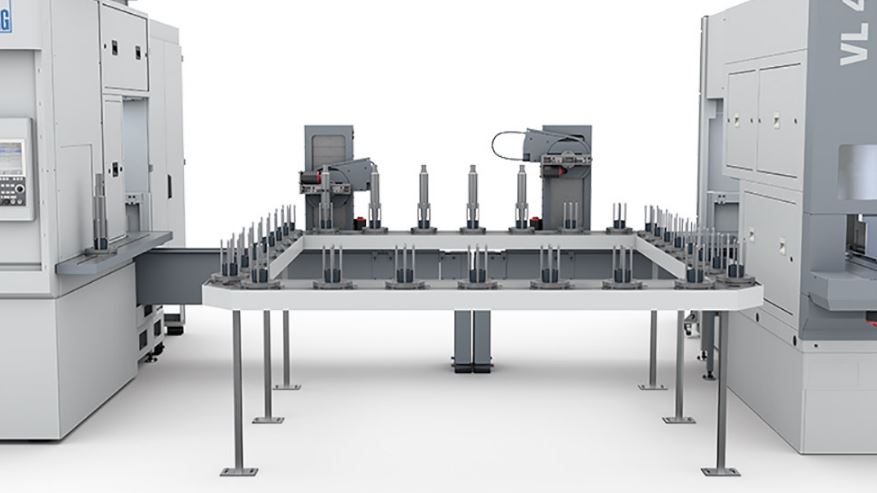

A continued rise in the demand for customized systems and integrated solutions was predicted back in 2014 by a survey of German manufacturers of plant and machinery, in a study on the future perspectives for the industry in Germany. This is not surprising given the huge “Industry 4.0” trend, as extensive automation in the form of customer-specific system solutions is a fundamental prerequisite for the digitalization of production facilities. The machines used then form an integrated system that production planners can control from a central point. Moreover, many companies need to respond ever more quickly and flexibly to technological developments. Numerous different versions of parts and fluctuating unit volumes are typical for small and medium-sized production companies in the automotive industry.

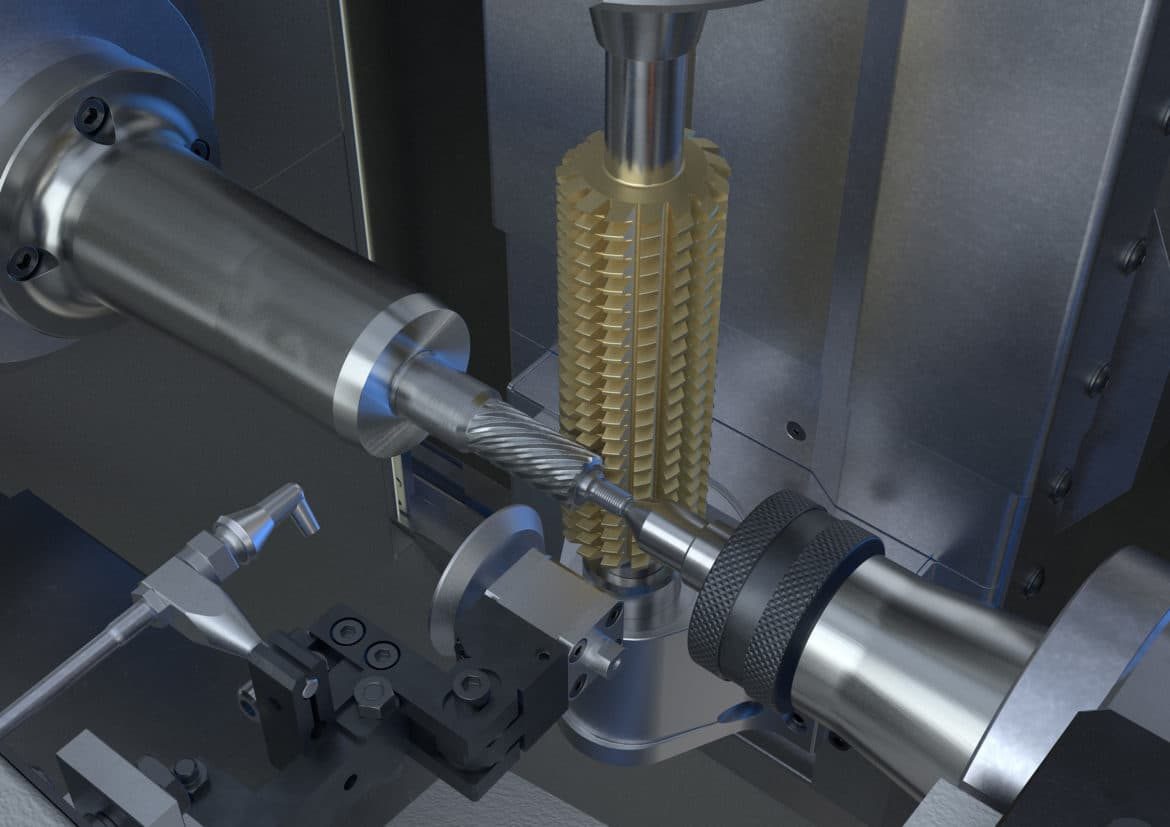

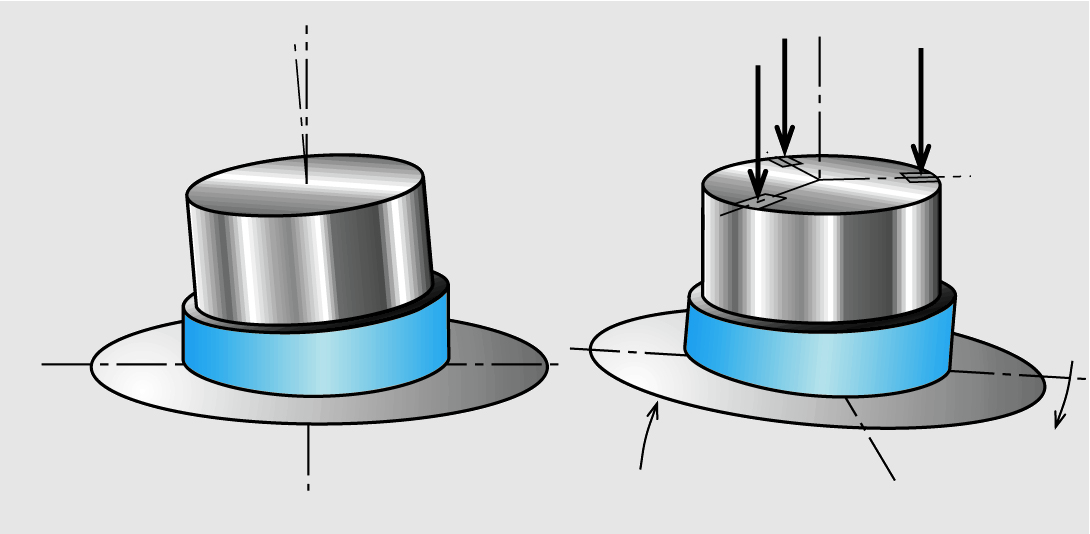

The EMAG Inverted Spindle Pick-Up Lathe process provides for a significant improvement in accuracy versus that of a sub-spindle lathe.

Lathes with sub-spindles pass a part from one rigid work holding system to another. This does not allow for any misalignment of the two spindles. The first spindle cannot release a part until the second spindle has a secure grip on it. Allowing for mismatches on a split turned dimension such as a bore. The accuracy and quality of the workpieces that are produced from this system are compromised because of this process.

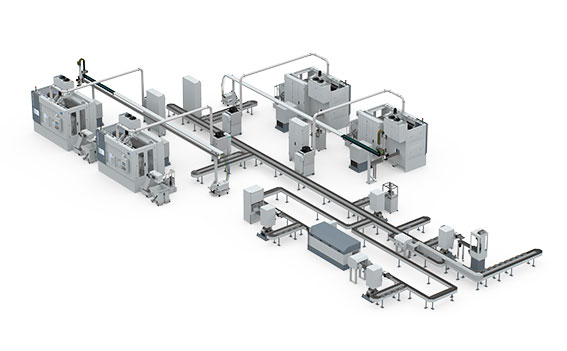

CVT transmissions are becoming increasingly popular in the American and Asian markets. The technology improves driving comfort as the car shifts gears more smoothly. A critical part of manufacturing these transmissions is the creation of the CVT components like shafts and disks (“pulleys”) that need to be hard machined with extreme precision– all as part of a multi-stage process that uses various turning centers and grinding machines.

When a leading tier 1 automotive manufacturer came to EMAG and asked us to meet their goals and needs for new differential lines, we had our work cut out for us. One of the unique promises made by EMAG is the company’s ability to achieve each customer’s needs. With this customer, their needs/goals included:

The automotive world is constantly changing and improving. The industry strives to create vehicles with better fuel economy, while also increasing safety and reliability.

The introduction of hybrid and electric alternatives are becoming more popular, and in the years to come we will see these options continue to grow. With this change, certain components of today’s gas driven engines will be replaced with new components and technologies.

Today’s competitive talent marketplace requires small and medium contract manufacturers and OEM’s to make the most of the talent they have. Skilled, experienced machinists are hard to find and having them tied up hand-loading parts into a lathe is seldom the best use of talent. So – how does a successful small to mid-sized shop meet their customers’ production requirements with the existing talent pool?

EMAG’s Standard Modular Vertical Turning Solutions for chucked and shaft like components continue to gain market share within North America.

For years EMAG has continued to develop and invest in new technologies that make them the leading OEM of Manufacturing Systems for Precision Metal Components. We’ve become known world-wide for our Vertical Turning technology along with our ability to provide complete process chains to the world’s leading Automotive OEM. We’ve become the prominent leader in gear box, engines, and chassis solutions within the automotive industry but can also provide solutions within Energy, Aerospace, Agriculture, Construction and Oil Field.

Increasing cost pressure, high demands on part quality and frequent change of batches – the manufacturing of car brake discs is a difficult field. Particularly in the spare parts market, where users must request individual machining solutions that can be retooled for new workpieces without long downtimes.