EMAG recently introduced the USC 850 CNC universal turning machine – a precision and powerful turning machine for large workpieces. In the following interview, Bernd Scheschy, Technical Sales in the Turning Business Unit, explains the technical features of this machine.

Machines

Whether you’re making transmission shafts, rotor shafts or even gun barrels, the challenges are consistent: high volumes, high precision, limited space and fewer people to get the job done. It can be a lot.

We caught up with David Fitzgerald, EMAG’s Regional Sales Manager, to talk about how the VT 4 vertical turning center is helping manufacturers check all the right boxes.

The requirements for shaft machining have changed significantly in recent years. Increasing variant diversity combined with decreasing batches present manufacturing companies with new challenges. With the VTC 100 GT EMAG is presenting a machine in which the turning, grinding, drilling and milling processes using a combined lifetool. In the following interview, Marina Manger, Technical Sales at the Grinding business unit, explains how this technology integration makes production more efficient and what concrete benefits users can derive from it.

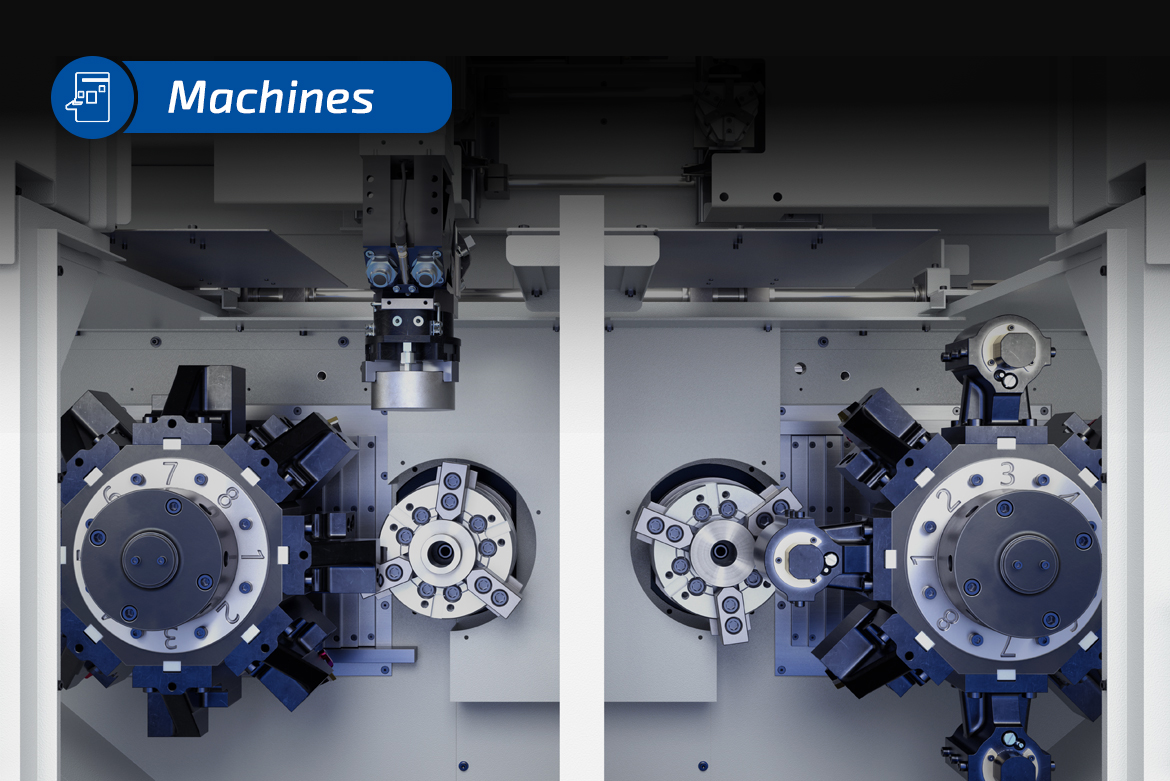

In the race to stay competitive, manufacturers are always searching for equipment that balances productivity, precision and affordability. EMAG’s Classic Machine series is designed to meet this challenge head-on. The machine front and center in this lineup, the MSC 5 DUO, exemplifies how “just enough” can be more than enough – especially when built on proven technology and smart engineering.

The 19″ FANUC iHMI operating panel from EMAG combines state-of-the-art control technology with ergonomic design. Ralf Mayer, Head of EDNA Operations at EMAG, gives an insight into the technical specifications and background of the new HMI.

Modern production systems are a key factor for the competitiveness of manufacturing companies. For high-quality cylindrical grinding machines, a comprehensive modernization of existing systems can be an economically interesting alternative to purchasing new equipment. CNC-Technik Weiss GmbH, part of the EMAG Group since 2019, specializes in retrofitting Karstens cylindrical grinding machines. The Neckartailfingen–based company has decades of experience in overhauling and modernizing these precision machines. In an interview with Andreas Holstein, Plant Manager at EMAG Weiss, we were able to talk about the technical possibilities and economic aspects of retrofitting.

An interview with Peter Gröner, Product Manager Business Unit Turning at EMAG, about the new MSC 5 DUO turning machine and its answers to current challenges in machining production.

“The combination of manual operation and automated functions allows operators to make the most of their experience while benefiting from the precision of the control system,” explains Andreas Hessling, Technical Sales Manager at EMAG Weiss, in an interview. The hydraulic-free W 11-EVO cylindrical grinding machine addresses key customer requirements: minimized energy costs thanks to servo-electric axes, highest precision thanks to scraped V-flat guides and an intuitive touch control for quick machine settings. The sophisticated operating concept shows its strengths particularly in the economical production of prototypes and individual parts. The operator retains direct control over the sanding process thanks to handwheels, while the servo-controlled axes ensure precision positioning and reproducible results.

The automotive industry is facing a major challenge: the Euro 7 standard stipulates strict limits for particulate matter emissions. Cars will then only be allowed to emit around three milligrams of particulate matter per kilometer – a drastic reduction compared to today’s values of up to 40 milligrams. To achieve these ambitious targets, car manufacturers are increasingly relying on innovative technologies such as coated brake discs.

Laser cladding is a promising process for manufacturing these ultra-modern brake discs. In this application, a special material powder made of stainless steel and hard carbide is welded onto the surface of the brake disc using a laser. The result is brake systems that not only drastically reduce particulate emissions, but also minimize wear and prevent corrosion.

However, the design and development of this new coating technology also creates new challenges in post-processing. With the VLC 450 DG grinding machine, EMAG offers a specialized solution for the machining of these high-tech brake discs.

We spoke with Jannik Röttger, Head of Grinding Technology at EMAG, about this innovative technology and EMAG’s response to the challenges of the Euro 7 standard.

The CLC 200 is a powerful gear hobbing machine that has been specially developed for the machining of gears, gear cutting shafts and worm gears up to module 5. In this interview, Alexander Morhard, Technical Sales Support Manager at EMAG SU, gives an overview of the most important features, advantages and areas of application.