Drilling rigs are complex systems that are used to drill deep boreholes into the ground – for example to extract crude oil or natural gas. The central element is the drill string, which consists of numerous steel pipes that are bolted together via threaded connections. These pipes and the connecting threaded sockets (couplings) must be able to withstand enormous mechanical stresses and seal absolutely reliably. In this blog post, we shed light on how a drilling rig and its pipe systems work and, in particular, how the machining of the pipes and couplings takes place. The focus is on machine tools from the EMAG Group – in particular the series USC (for pipes) and VSC (for couplings), which are used in the machining of OCTG (Oil Country Tubular Goods) components.

1. How is a derrick constructed and what role do pipes and couplings play in it?

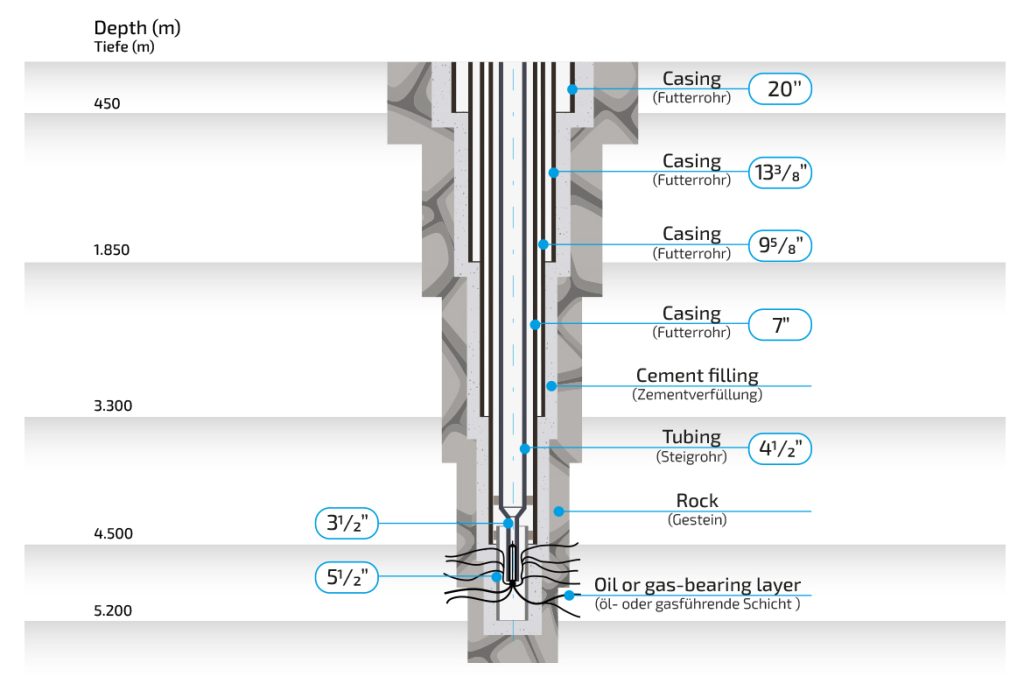

A derrick is a tall steel structure that is erected above the borehole and serves as a central lifting and guiding frame for the drilling work. Inside the derrick are hoists (pulley block) and a high-torque drive (either a turntable on the ground or a modern top drive in the derrick), which rotates the drill string. The drill string itself consists of many individual drill pipes that are bolted together to form an ever-lengthening pipe string. In this way, the required depth is gradually reached. The drill bit, which breaks up the rock, sits at the lower end of this pipe string. The pipes are screwed together either via welded-on tool couplings (in the case of drill pipes in the form of integral tool connections) or – particularly in the case of delivery and casing pipes – via separate threaded sockets. A threaded socket is basically a short, thick-walled piece of pipe with an internal thread at both ends that connects two pipes. During drilling, the individual pipes are continuously added or removed using these threaded connections. Later, after reaching the final depth, the borehole is lined with larger casing pipes, which in turn are screwed together with couplings and cemented to provide a stable lining for the borehole. Threaded connections are also used in the production tubing to safely guide the pumped medium upwards.

A classic derrick with lifting tools for handling the drill pipe.

Why are these pipes and couplings so important? They form the backbone of the drilling operation. The threaded connections must be able to bear the entire weight of the drill string (sometimes several hundred tons) while rotation and often bending take place at the same time. In addition, the casing connections, for example, must be able to withstand the internal pressure and corrosion. Failure of the connection would have serious consequences – from loss of the drill string to blowouts. The demands on the accuracy of fit and load-bearing capacity of the threads are correspondingly high. The quality of these connections is largely determined by the precision machining of the thread profiles on pipes and couplings. This is where turning machines – such as the EMAG USC and VSC series – come into play, which are designed for such tasks.

Schematic representation of the structure of a cased oil or gas well during the production phase.

2. What are the requirements for threaded connections (API, GOST, Premium)?

Threaded connections for drill pipes and couplings are subject to strict international standards and specifications. API (American Petroleum Institute) standards (e.g. API 5CT for casing/tubing threads) and the Russian GOST standard are the most common worldwide. These define the geometry and tolerances of the threads very precisely so that components from different manufacturers are compatible. Typical API thread profiles are, for example, API Round Thread (round-profile thread, usually on casing pipes) and API Buttress Thread (trapezoidal thread profile with high shear strength, often on casing pipes). GOST profiles are similar for the Eurasian region. In any case, such standard threads must be manufactured with precision. Thread pitch, flank angle, diameter and length dimensions are subject to tight tolerances in order to guarantee the tightness and strength of the connection.

There are also so-called premium threads. These are gas-tight, company-specific special threads that go beyond the API requirements. Premium connections often have optimized profiles with gas-tight metal-to-metal seals, higher torque transmission and improved sealing and joining surfaces. They are used when there are special requirements – such as very high pressures, deep bores, frequent assembly and disassembly cycles or corrosive environments. Premium threads generally require even higher manufacturing accuracy and more complex profile shapes.

The general requirements for all these threaded connections are: high dimensional accuracy, surface finish without notch effects and reproducible quality of each individual thread. Production, therefore, requires strictly controlled processes – from the right material and heat treatment to the final inspection. For example, material quality, tensile strength, notched impact strength, thread form (profile, pitch per inch, taper) must be exactly right and are checked using appropriate tests and gauges. The tolerances are often even tighter for premium connections. Modern machine tools such as those from EMAG are capable of producing all these different thread types with the highest precision. The EMAG VSC & USC machines cover all threads required in the oil field – from API and GOST to Premium.

A practical example of a requirement is tightness. In many connections, the thread also performs a sealing function. Here, the thread flanks and, if necessary, shoulder surfaces must be machined in such a way that they are metallically tight under tightening torque (in addition, sealing rings or special greases are often used). This also places high demands on the manufacturing accuracy of the thread profiles.

High-precision machined couplings and pipes with threaded connections to API, GOST and Premium standard.

3. How are pipes machined?

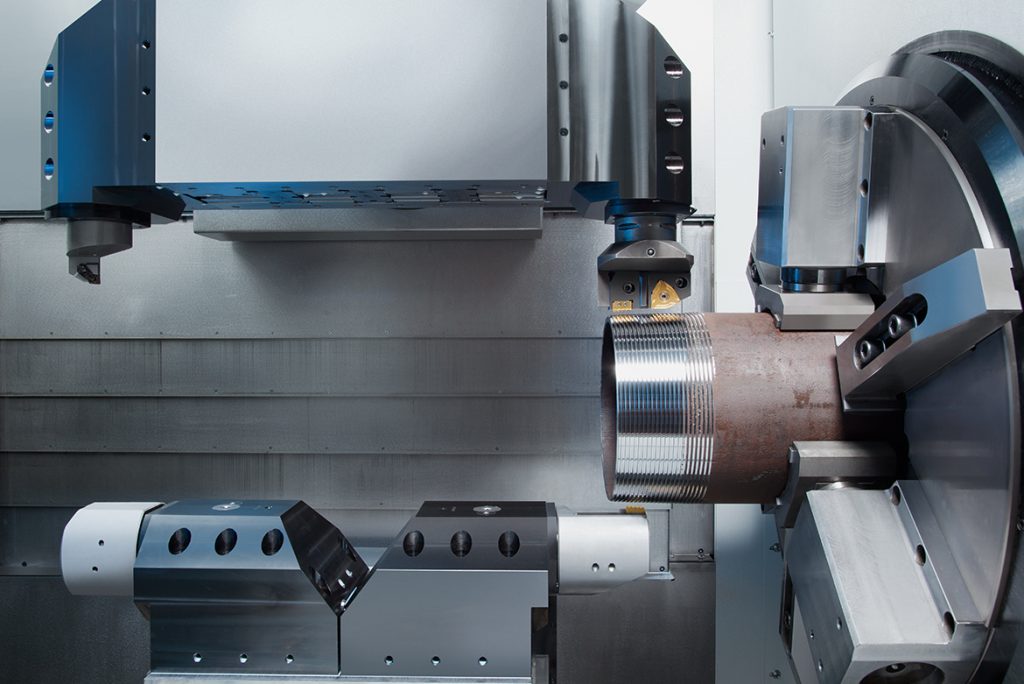

The machining of tube ends (external threads, end faces, chamfers, etc.) is carried out on special lathes from the EMAG USC series. These machines are specifically designed for pipe machining and have an extremely rigid structure. The machine base body made of polymer concrete (MINERALIT®) ensures high stability and vibration damping – a decisive factor in absorbing the high thread cutting forces with precision. All important assemblies (headstock, tooling system, bed) have a robust design and are mostly fluid-cooled to ensure thermal stability.

A central feature of the USC machines is the integrated main spindle drive. The spindle motor is built directly into the spindle unit (direct drive) and delivers high-performance and high torque. This means that even large pipe diameters can be machined with corresponding cutting forces. With a main spindle power of 120 kW, the USC 21 has sufficient power reserves to efficiently cut even 16″ thread sizes in steel. In addition, the direct drive enables extremely precise positioning of the spindle (important for thread starts and multi-tooth thread cutting inserts) as well as rapid braking/acceleration in the thread cut, which optimizes the process time. This precision is not easily achieved with conventional belt or gear-driven spindles.

For pipe clamping, USC machines have a double chuck system — one chuck at the front and one at the rear of the spindle. Both grip the tube synchronously at the front and rear hydraulically (optionally pneumatically or mechanically) and center it precisely. This ensures that the tube is stably supported over its entire length during machining. Centering devices are also available. Separate NC-controlled centering quills can be positioned on the inside or outside of the tube for support. A pipe stop device and a unit for inserting detachable plugs are also available. The latter is used to insert an inner plug into the tube ends, which acts as a support against vibrations, especially during thread machining, and is then uncoupled again.

2-axis, 4-axis and 6-axis machining: the USC 21 series can be configured modularly for simple 2-axis machining as well as for multi-axis machining. In the 2-axis version, the machine works with a single turret and machines the tube ends sequentially (all machining steps one after the other). This configuration is robust and is sufficient for standard threads with moderate quantities, for example.

The 4-axis variant is used far more frequently. Here, two turrets are available – usually an upper and a lower turret – which work simultaneously on the workpiece. This means that two tools can be engaged on one tube ends at the same time. In practice, for example, one turret is often used to machine the external contours while the other turret works on the inside of the tube (for the internal contour and for turning the end faces). Alternatively, both turrets can also share the external machining of the thread (one roughing, the other finish-machining at the same time). The 4-axis machining leads to significantly shorter machining times and is particularly advantageous for premium threads with several machining steps.

The 6-axis machining takes the principle even further: In this expansion stage, for example, the upper turret has a double compound slide (two irrespective X-Z slides on one side) so that two tools can machine different positions on one tube end at the same time. Together with the lower turret (2 axes), this results in six CNC axes. In practice, three tools can even be in use at the same time – for example, one tool for taper turning and thread cutting, one tool for the external chamfer, end faces and internal chamfer, while taper turning and thread cutting may run in parallel at the bottom.

The 6-axis solution is predestined for maximum productivity in production lines with high throughput and many premium connections, as it drastically reduces the cycle time per tube. The parallel use of several tools also eliminates time losses, for example due to turret rotations – many machining operations take place simultaneously.

In summary, the USC pipe processing machines offer maximum flexibility and efficiency. All common thread types – be it an API, GOST or a complex premium/integral internal (BOX) / external (PIN) thread – can be produced on one and the same machine. Thanks to the rigid machine design and precision axes, they achieve the required thread quality (profile accuracy, flank angle, pitch) with process reliability.

View into the work area of the USC 21 from EMAG with two turrets for simultaneous machining.

4. How is the machining of threaded sockets carried out?

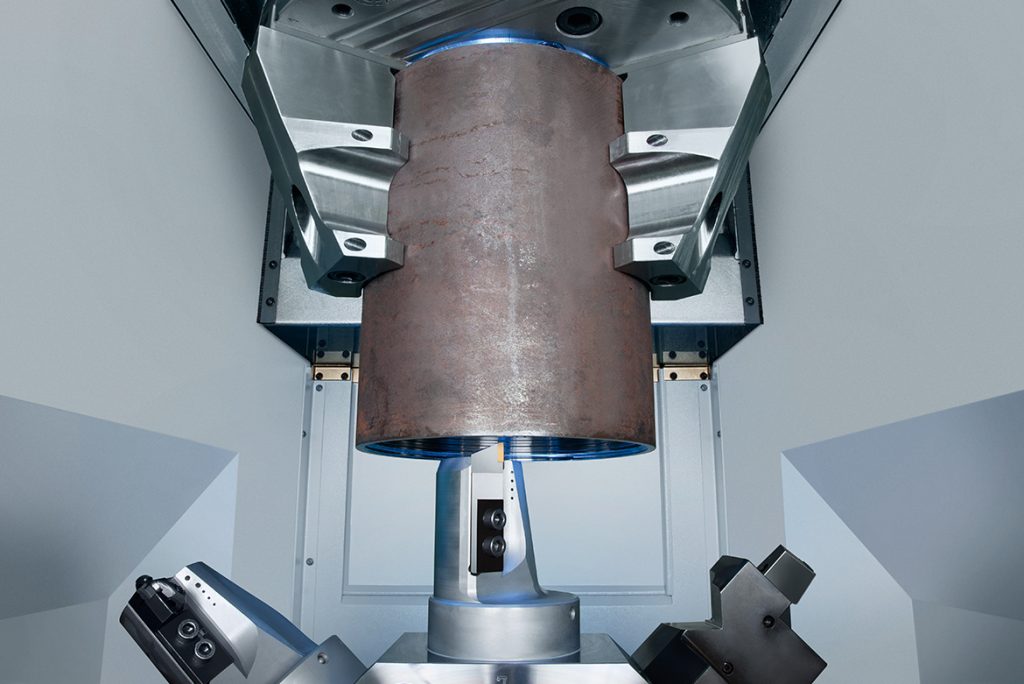

For thread machining on couplings – the short connecting pieces with internal threads – EMAG has various machine concepts in its program, in particular the vertical turning machines of the VSC series. Couplings are typically similar in diameter to pipes, but relatively short. They have internal threads on both sides, which must be cut with precision. Machining is usually carried out in two clamping operations: roughing (internal turning of the first half of the socket) and the actual thread cutting and, if necessary, turning of the sealing surfaces. Outside the work area, the half-machined couplings are turned through 180°. The second half of the socket is then machined. EMAG offers both single-spindle and double-spindle machines, depending on the required output quantity.

VSC series (vertical pick-up turning machines):

The EMAG VSC 450 and VSC 500 are vertical turning machines that have been specially adapted for socket machining. The special feature of vertical machines: The work spindle is positioned vertically above the workpiece and also serves as a loading system (pick-up spindle). This means that the spindle can move out of the work area, grips the raw-parts (couplings blank) from above and brings it into the work area independently – without the need for a separate handling device. This principle turns each machine into its own manufacturing cell, shortens loading distances and times enormously and simplifies link-up in lines. In the machine, the couplings are clamped in a six-jaw chuck. The six clamping jaws distribute the clamping force evenly all around – important for securely clamping the usually relatively thin-walled but short couplings without deformation. The turret with the tools is positioned at the bottom of the work area on the VSC. This arrangement – tools under the workpiece – has the advantage of an ideal unhindered chip flow. Gravity transports the chips directly downwards without them being deposited on tools or guides. In addition, all sensitive guides, measuring systems and ball screws are mounted above and outside the work area and protected by covers. This means that coolant and chips hardly ever reach critical areas, which increases durability. The machine base made of mineral casting also ensures high rigidity and damping – important for interrupted cuts.

A practical problem when threading couplings is the chips that are produced. The continuous cuts often produce long, ribbon-shaped chips. In a vertical machine, these would in principle fall downwards; however, with small coupler diameters (e.g. 60-90 mm), the thread spiral chips tend to curl up into a ball and remain inside the coupler. EMAG has integrated a clever solution for this. Once the thread is complete, a high-pressure blast of cooling lubricant is shot through the chuck directly into the coupler via the spindle, which reliably removes the ball of chips from the coupler. This ensures that no chips remain in the finished thread. In general, high-pressure coolant is also used during thread cutting during machining to break up and remove the chips.

For high output quantities, EMAG also offers the VSC machines as a DUO version – e.g. the VSC 500 DUO. Two spindles are installed next to each other on separate spindle slides. Both spindles work in parallel and can each machine one half of a socket, which almost doubles the number of pieces per hour. The automation is designed so that the pick-up spindles are loaded and unloaded irrespective of each other. EMAG uses a shuttle with several pallet spaces for this purpose. Blanks are placed on two pallets, while finished or semi-finished couplings are placed on two others. The spindles pick up new raw-parts one after the other and deposit the machined components. This principle enables uninterrupted operation – a key to highest productivity levels. Even if only one spindle is producing (e.g. during a tool change on the other), the system can continue to run.

Another highlight is the ability to accept blanks that have not been sawn cleanly. The ends of the delivered pipe sections are often not exactly right-angled, but slightly slanted (“trapezoidal” shape of the section). The VSC pallets are spring-mounted so that when picking up such a slanted couplings, the flexibility of the spring compensates for the slanted cut up to approx. 1.5 % of the diameter. In concrete terms, with a diameter of ~200 mm, a misalignment of around 3 mm can be compensated.

Vertical work area of the VSC 500, optimized for perfect chip removal and precision socket machining.

5. What are the advantages of integrated EMAG manufacturing solutions for pipes and couplings?

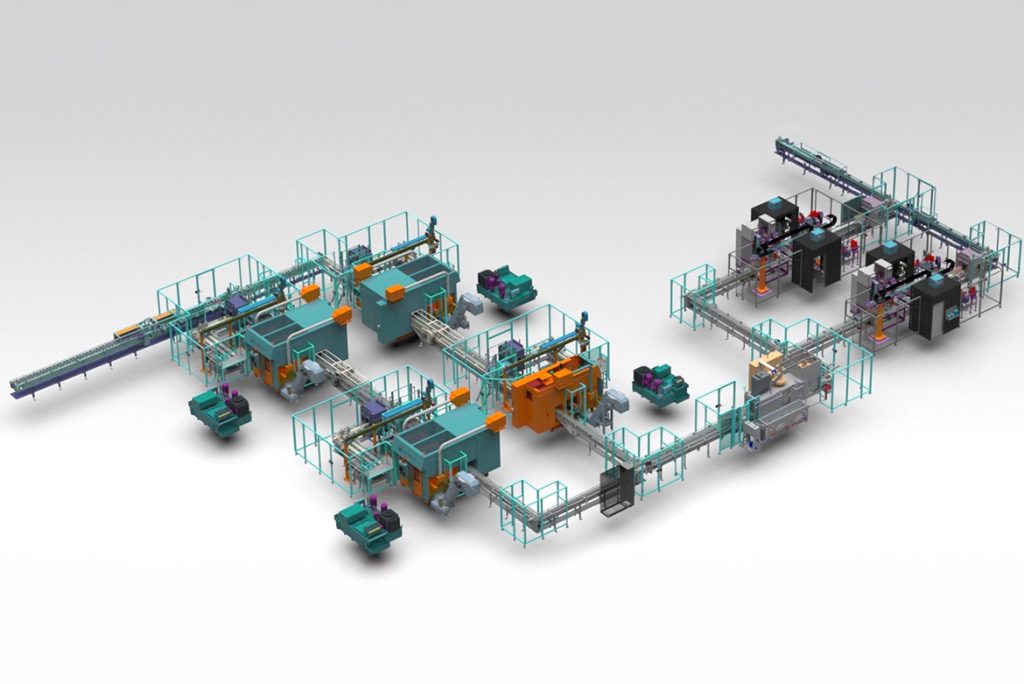

EMAG sees itself not only as a machine supplier, but also as a system provider for complete production lines. This means that complete process chains for the production of OCTG pipes and couplings can be realized from a single source – from the raw material to the finished threaded pipe/coupling, including all ancillary processes. This has considerable advantages for the customer:

- Turnkey solution & one point of contact: EMAG supplies turnkey systems in which machines, automation and process steps are perfectly coordinated with one another

- The customer has a central project partner, which makes coordination easier.

- All interfaces between e.g. tube feed, lathes, measuring stations, cleaning systems, etc. have already been thought through by EMAG Engineering – this shortens the commissioning time and minimizes integration risks.

- Continuous automation and link-up: Integrated solutions from EMAG typically include conveyor systems (e.g. roller conveyors for pipes, gantries or robots for couplings), loading systems (pick-up or shuttle) as well as intermediate storage and outfeed systems. This creates a continuous material flow without manual intervention. This not only reduces personnel costs, but also guarantees reproducible cycle times. Footprint and interlinking costs are also reduced, as the machines handle their components themselves, e.g. by means of pick-up, and can be placed back to back in compact lines.

Production line consisting of several EMAG machines for the fully automatic machining and quality inspection of OCTG couplings.

Ultimately, an integrated EMAG manufacturing solution for OCTG components means minimized risk and maximized benefit for the customer. The interaction of all components has been tested by the manufacturer, and responsibility for cycle time, quality and function of the overall system lies with one partner. The high level of automation reduces human error and increases process reliability. Thanks to fast cycle times and optimized material flow, unit production costs can be reduced. And the excellent manufacturing quality of the EMAG machines ensures that the finished pipes and couplings perform reliably in the field.