In many ways, the production of large components presents a particular challenge in manufacturing. Used in commercial vehicles, large transmission, or wind power, these parts are large – making them difficult to handle and slowing down production speeds. Adding to the production challenge is the additional technological requirements being placed on the parts, as well as the demand for improved reliability and precision, with decreased costs per piece. All of which needs to be achieved while improving process speeds.

Machines

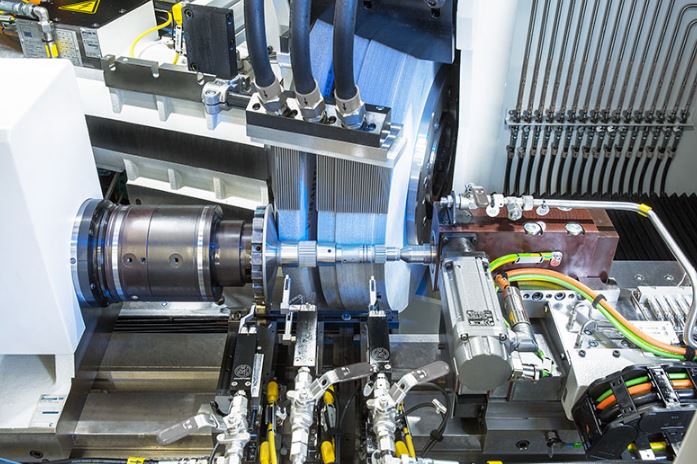

Cylindrical grinding on driveshafts and transmission shafts has always been particularly demanding, as the parts feature a wide range of geometric details that are machined with high precision in the grinding machine. With the rapid pace of technological development in the automotive industry, which keeps increasing the functional density of many components, there are more demands than ever on the design of grinding machines today. Users require highly customized machines that can perform multiple grinding operations, including combined internal and external grinding.

Maximum flexibility is required for gear production. EPS steering is a good example: Production planners for this application are looking for machines that can efficiently and completely cut an EPS steering gear including steering pinion, worm gears, and screws. The HLC 150 H horizontal gear cutting machine from EMAG KOEPFER is the perfect solution for this.

The EMAG Inverted Spindle Pick-Up Lathe process provides for a significant improvement in accuracy versus that of a sub-spindle lathe.

Lathes with sub-spindles pass a part from one rigid work holding system to another. This does not allow for any misalignment of the two spindles. The first spindle cannot release a part until the second spindle has a secure grip on it. Allowing for mismatches on a split turned dimension such as a bore. The accuracy and quality of the workpieces that are produced from this system are compromised because of this process.

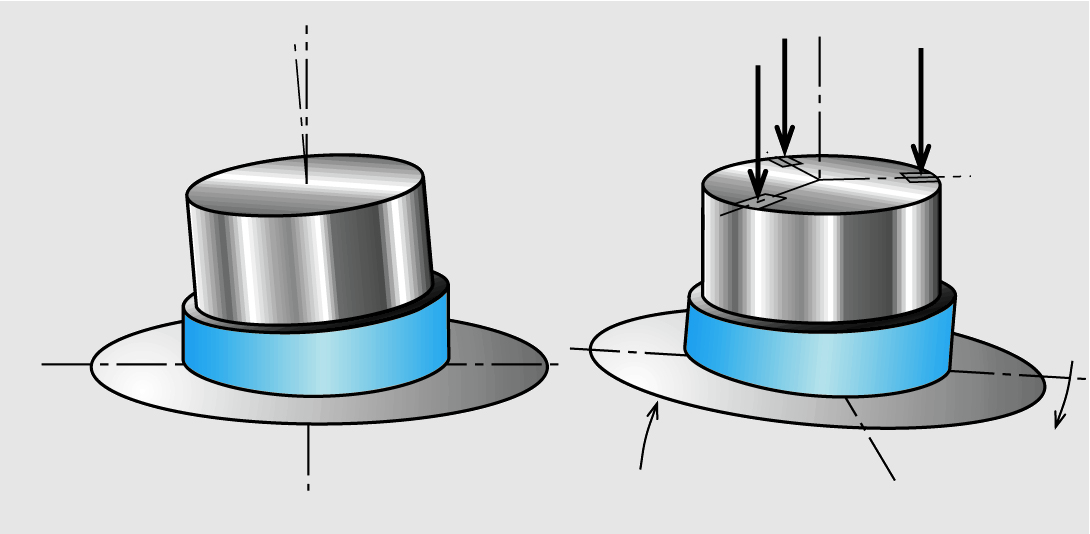

Increasing cost pressure, high demands on part quality and frequent change of batches – the manufacturing of car brake discs is a difficult field. Particularly in the spare parts market, where users must request individual machining solutions that can be retooled for new workpieces without long downtimes.

The VLC 200 GT is loaded at by the integrated pick-up spindle. The process starts with hard pre-turning of the shoulder and the bore hole in quick succession. Only a few micrometers of material are then left to be removed from the automotive gear by the subsequent grinding process, using either aluminum oxide or CBN grinding wheels.

Transmission manufacturing is among the most innovative areas of passenger vehicle production: This central component has to ensure a high level of driving dynamics, while keeping fuel consumption low at the same time. Transmissions are therefore becoming smaller and lighter, and provide a higher number of speeds. The individual gearwheels are a main focus of the developers. Their production in extremely high volumes requires a high level of efficiency—at high precision, high speed, and highly controlled.

Maximum Efficiency in Shaft Production. Short cycle times, high precision and safe processing are among the outstanding attributes of shaft machining on the turning machines of the VT series. These lathes literally turn the classical horizontal machining process on its head.