The EMAG Technology Forum will take place in Salach on May 15 and 16, 2019

Technologies

EMAG employs more than 3,000 people worldwide. In addition to the modern production facilities in Jintan and Zerbst, the heart of our company resides at our German technology sites.

EMAG laser technology has become essential in the production of modern transmission components – the ELC machines (EMAG Laser Cell) enables effective lightweight car construction with lower component costs. The laser specialists from EMAG based in Heubach, near Stuttgart, have changed their name to “EMAG LaserTec”. What’s the reason for the change? – An interview with EMAG LaserTec Managing Director Andreas Mootz about growing success, new technologies and promising applications explains.

According to a new study by PwC, an automotive consultant firm – there are five dimensions that influence change in the automotive industry. The car of the future is electric and connected, increasingly autonomous, more integrated in sharing concepts and models are updated on a yearly basis (!)—making eight year model cycles a thing of the past. How can such a fast and radical change be implemented on the shop floor? What happens to the old machinery and to the existing production lines? A discussion with Markus Heidel, Head of the EMAG plant in Eislingen, responsible for retrofitting and retooling, reveals that the answer relies not only on investment in new machines – but also retrofitting. The specialists at EMAG will ensure that existing machines and production systems are prepared for changing manufacturing processes with the help of some conversion work – offering an attractive alternative to purchasing new equipment.

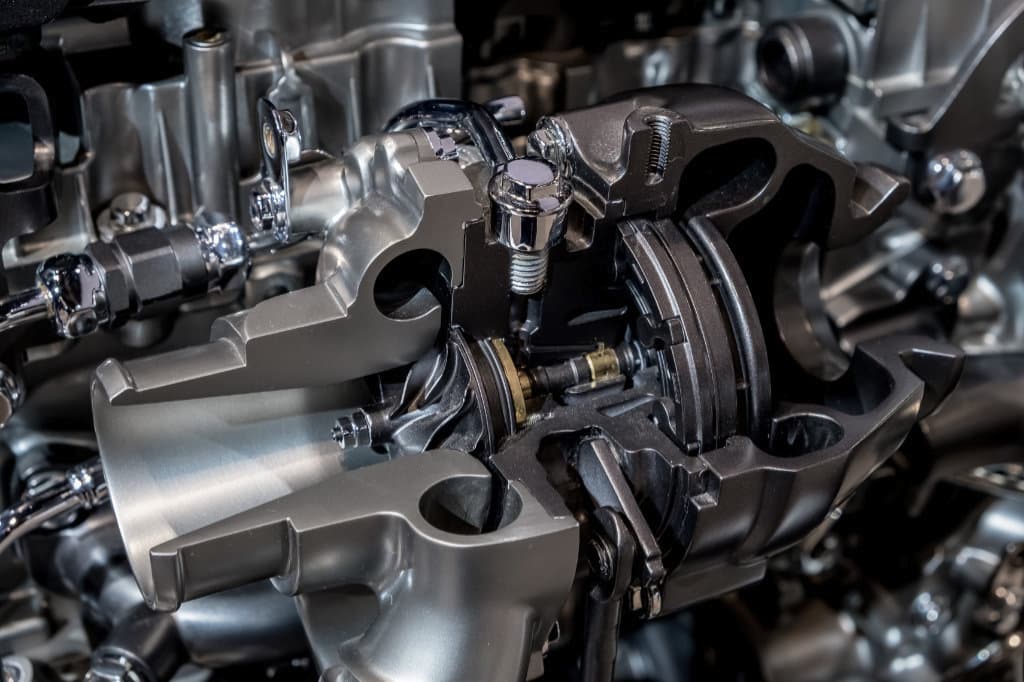

Historically, the power of a car’s engine was dependent on the number and size of cylinders – today, that’s a thing of the past! Electronic engine control, turbochargers or compressors are responsible for the overall performance. The turbocharger has a particularly important role—a Swiss invention dating back to 1925, the turbocharger was used to considerably increase engine power. What distinguishes this component, why is it increasingly important and what are the benefits of using electrochemical machining? —Five interesting facts about turbochargers:

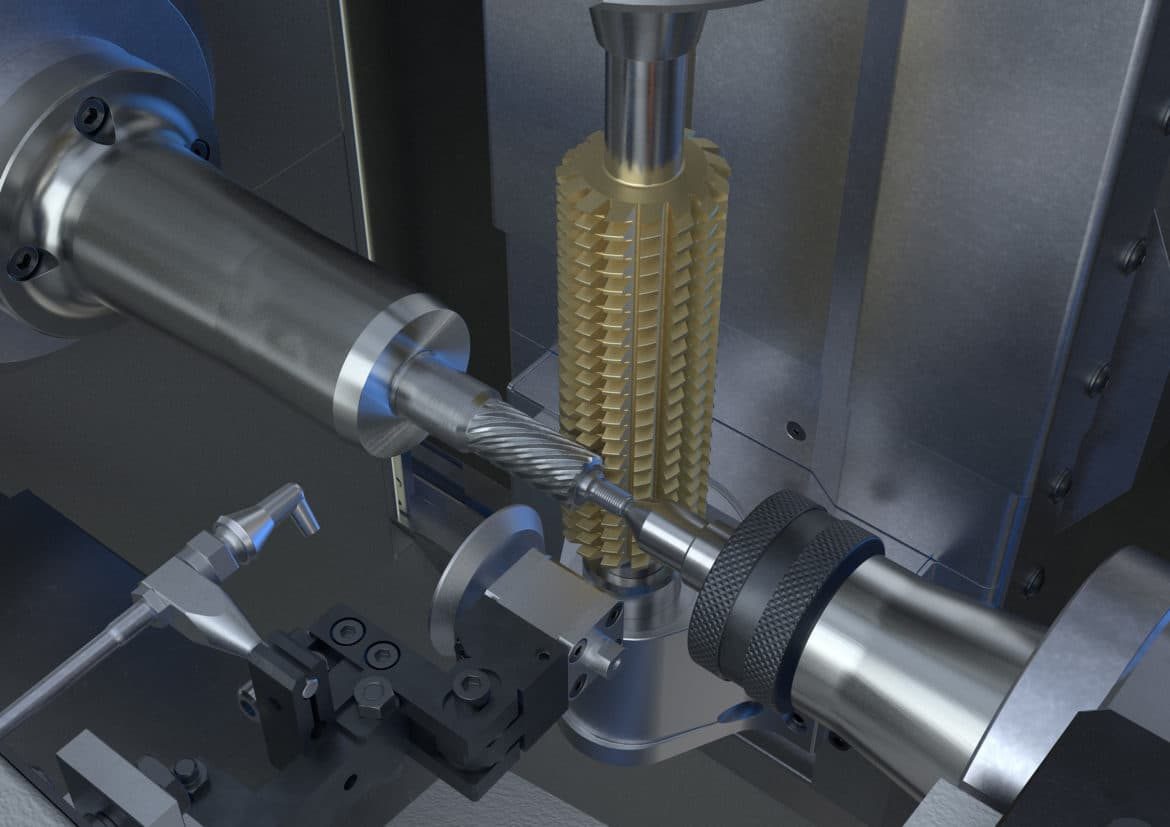

The Swiss company Humbel has been involved in gear production since 1928—specializing in particularly sophisticated types of gears and transmission components, eventually evolving into a full-service supplier. At their facility in Kradorf, approx. 20 kilometers (12 miles) from St. Gallen, they produce both individual parts as well as complete assemblies. The company recently expanded their machine inventory to include a VL 4 vertical turning center by EMAG. — We spoke with Alex Humbel, Managing Director of Humbel Zahnräder AG in Kradolf, on the challenges facing gear producers, the importance of E-mobility, as well as their company strategy.

Which sector of industry is the most innovative in Germany? A very comprehensive answer to this question has been provided in the report entitled “Innovation in the German Economy” issued by the Center for European Economic Research (Zentrum für Europäische Wirtschaftsforschung GmbH, ZEW). The current issue rewards automotive manufacturing, among others, with a good score. According to the report, the automotive industry has the highest amount of innovation in its production (48.3%). Innovation is fundamental to the automotive industry’s economic success. Additionally, the industry’s “innovation expenditure” identified by the ZEW is increasing. In 2016, this was valued at 47 billion euros and, according to estimates; it should increase to nearly 55 billion euros by the end of this year.

Exactly 1,223 innovations saw the light of day in the automotive industry last year—at least that’s according to a count conducted by the Center of Automotive Management and the consultancy firm PwC. About 27 percent of these innovations pertain to driver assistance and safety systems—one in five belongs to the field of engine construction. Considering the corresponding automotive production, one trend that has been going on for years still holds true: The pace of change is always increasing as the requirement for more flexible production continues to increase. It is important that new parts and components can be produced efficiently, and defect free using existing product solutions.

Electric power steering has become standard in the manufacturing of automobiles. The technology guarantees very precise steering support for every type of vehicle, high-end driving comfort, and lower energy consumption in the steering system, which has a positive effect on the car’s CO2 consumption.

The revolution in car manufacture is happening subtly: Our cars are mastering an increasing number of situations without driver intervention. There is a large number of assistance systems which keep the vehicle on track or avoid obstacles. Recent models even park independently or drive into the garage. This requires the driver to take their hands off the steering wheel entirely. Experts divide the current development into phases: The assistance systems described above have already become a reality. As a partially automated system, parking assistance belongs to phase two. In a few years, fully automatic, driverless operation will follow as the last phase.