IMTS 2024

Meet EMAG - Automated Manufacturing Solutions for Higher Productivity

If your company machines metal components, manufactures gears, uses laser welding or electro-chemical machining, EMAG can provide state-of-the-art machinery – from stand-alone pick-up turning machines to complete equipment cells capable of machining entire workpiece families. With decades of experience in the precision manufacturing space, our group can provide you with the technology and experience needed to complete even the most challenging applications.

Date: September 9-14, 2024

Location: McCormick Place, Chicago, Illinois USA

Stand: North Hall, Booth # 237047

Our Highlights:

VL 3 DUO Turning Machine

EMAG‘s exhibit will include a demonstration of the manufacturing capabilities of the VL 3 DUO Turning Machine, which is available with our pick and place loading solution. This dual turret machine will provide hours of autonomous part production and caters to many part varieties up to 150mm in diameter, including gear manufacturing.

WPG 7 Universal Cylindrical Grinding Machine

We’ll also display our WPG 7 Universal Cylindrical Grinding Machine – a compact, highly productive, flexible and affordable external grinder designed for small and medium-sized workpieces up to 250 mm long and with a maximum diameter of 200 mm. These machines can also be automated to increase production efficiency.

VT 4 Turning Centers

Short cycle times, high precision and safe processes are what distinguish shaft machining on VT series turning centers. In these turning centers, traditional horizontal machining has literally been put on its head. Equipped with either FANUC or Siemens controls, VT 4 / VT 200 are designed for shaft parts up to 630 mm long and up to 200 mm in diameter.

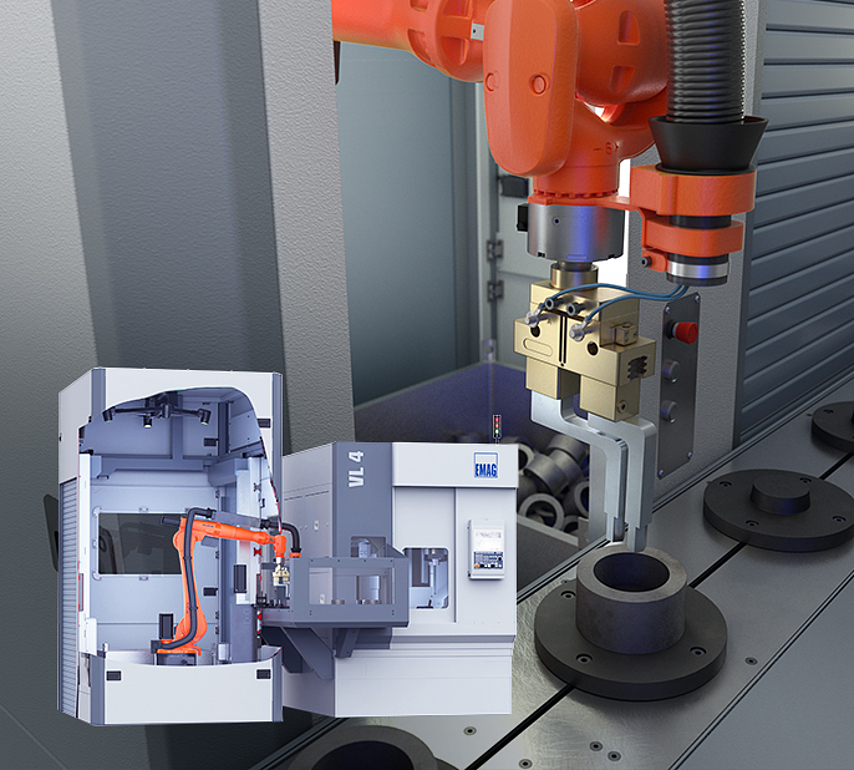

Bin Picking Automation

Bin picking, or "reaching into the box,” is a technology in which a robotic arm uses a 3D sensor system (3D camera, scanner, ...) to remove workpieces in a chaotic position from a mesh box or similar. The automation then correctly aligns the parts and feeds them to the next processing step. This can be, for example, the loading of an EMAG pick-up lathe. Bin picking is ideal for automated handling of workpieces such as saw cuttings or forged parts in chaotic feed or when high flexibility is required.

We look forward to meeting with you!

EMAG’s integrated automation solutions and precision manufacturing equipment are designed to provide one complete source for all our customers manufacturing needs. Stop by booth 237047 and put our experience to work for you.