레이저 용접 기계

ELC 6

- External diameter, max.: 300 mm | 12 in

- Workpiece height, max.: 300 mm | 12 in

- Axial welding diameter: 75 / 200 mm | 3 / 8 in

Laser Welding Machine ELC 6

The EMAG ELC 6 is a production laser welding system for maximum output and is ideal for classic powertrain components with round welds. The machine is based on a rotary indexing system with a machining station and a loading and unloading station.

Production Laser Welding System for Maximum Output

The main features of the ELC 6 are as follows:

- Maximum operating safety thanks to the “Fixed lens/moving workpiece” principle

- Rotary indexing system to achieve the best possible cycle time

- Initial tension for welding up to max. 10 kN possible (30 kN available as an option)

- Compact design and excellent accessibility

- Short retooling times

- Minimization of equipment and change parts

- Low operating costs using high-effi ciency lasers and mainly electric drive units rather than pneumatics and hydraulics

- High level of fl exibility in terms of technology, output, and automation

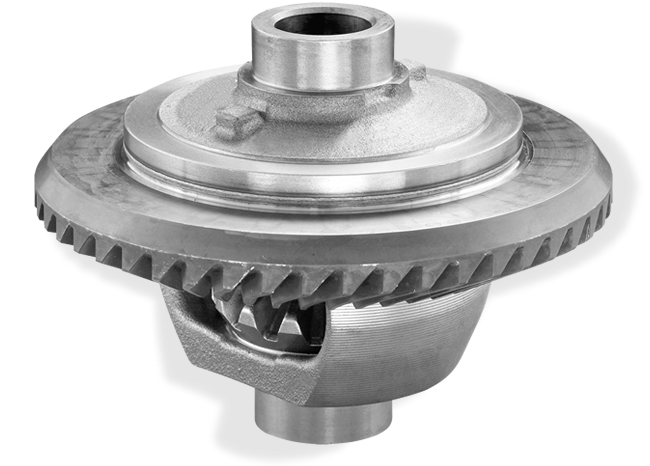

공작물

The Right Manufacturing Solution for Every Workpiece

기술

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Laser welding is a precondition for compact, weight-optimised components and thus for energy- efficient vehicles. Adjustable doses of concentrated…

기술 데이터

External diameter, max.

300 mm

12 in

Workpiece height, max.

300 mm

12 in

Axial welding diameter

75 / 200 mm

3 / 8 in

| External diameter, max. |

mm

in |

300

12 |

| Workpiece height, max. |

mm

in |

300

12 |