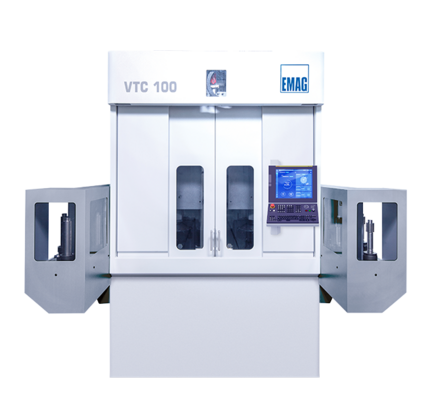

Live at EMO 2023

Whether you are looking for solutions for single processes or subprocesses, or wish to reproduce the entire process chain from raw part to finished part—at the EMO 2023, the EMAG Group offers you a comprehensive overview of their full bandwidth of technologies and manufacturing solutions.