Home

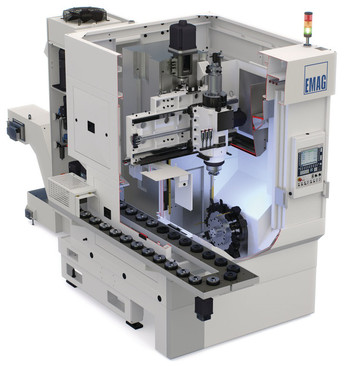

With the new VL product family for machining chucked components and the VT for shafts, EMAG presents a new generation of lathes that provide maximum performance at a reduced cost per part. Based on the extremely successful vertical pick-up system invented by EMAG, over 20 years of experience in machine solutions was utilized to develop this new model to comprise one of the most flexible and effective manufacturing systems currently on the market.

Aiming to develop a system of modular machines ideal for use in the manufacturing of medium and large batch runs, one common feature of all the new EMAG modular machines is the shared, basic, compact design. Their small footprint means reduced floor space costs and flexibility in machine layout (for example, Chaku Chaku or closed loop arrangement). Every VL machine features an integrated O-automation for transporting workpieces. Combined with the self-loading pick-up spindles this ensures short cycle times and high productivity. To accommodate machine operators, all the service units are easily within reach, with the various units (electrics, hydraulics, cooling system, cooling lubricant and central lubrication system) accessible at any time so that the machines can be maintained with ease.

The VL series vertical pick-up turning machines were specially developed for manufacturing precision chucked parts with machines available in four sizes to cover as wide a range of project sizes as possible. The VT series offers two sizes for shaft production. The range of modular machines increases with custom technology options, such as vertical grinding, gear hobbing, chamfering, induction hardening, laser welding and electro-chemical machining all available on the same platform.

More information and videos available for the VL Series and VT Series.