The VMC / VMC-MT Series

With the VMC and VMC MT series, EMAG offers a single machine system for chucked parts, designed for the production of a wide variety of workpieces in many different manufacturing scenarios. The flexibility of the machine makes it a perfect fit in any production process. Be it parts for trucks, construction and agricultural machines or the aviation industry, the VMC-series is ideal for practically every industry sector.

Adaptable to Optimally Fit Machining Requirements

The vertical turning centers of the VMC series are designed for the manufacture of small and medium production runs with a wide variety of parts. The tool turret is equipped with eight to twelve tool positions for machining, depending on the desired tool interface (BMT or VDI). For example, the turret can be equipped with driven tools to carry out drilling operations. An integrated probe ensures process reliability and guarantees consistently high workpiece quality (first part = OK part). All these qualities make the VMC series very well equipped for a wide variety of production tasks.

The VMC MT series diversifies the machine concept with the addition of the turning/milling spindle positioned at the top of the macine to form a highly flexible production center. The machines focus on universality allows it to be configured to meet almost any customer request. Complete machining using a wide variety of technologies is a key feature. The VMC MT-series offers various tool magazines with up to 80 available tool positions and various spindles to compliment this range. With its very high overall equipment effectiveness,the VMC MT series is an all encompassing solution for the machining of a wide variety of workpieces.

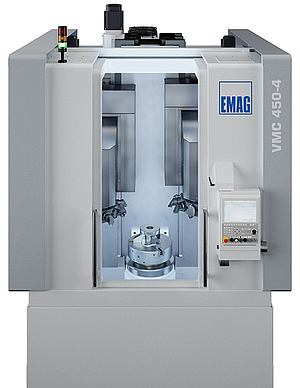

Four-axis Machining for Maximum Productivity

While the basic versions of the VMC vertical turning machine are already highly productive machining centers, productivity is significantly increased on the four-axis VMC 450-4 version. Four-axis means that the machine has an additional two linear axes, X2 and Z2, in the form of a second tool turret. The two tool turrets, enabling four-axis simultaneous machining from two sides, are supported by the powerful main spindle. The main spindle, available in a range of versions, allows for even heavy-duty machining processes and ensures an optimal material removal rate, which can be almost doubled thanks to the four-axis machining.

The high precision control of all axes together, paired with the almost limitless variation in tool use, allows for the production of complex components in a single clamping operation. Whether it requires hard and soft turning operations, drilling or milling operations, or gear cutting – the vast technological knowledge of the EMAG Group allows for a wide range of applications on the VMC 450-4.

Complex Geometries and Fast Turning Processes

The VMC 450-5 MT allows for the machining of heavy components with angled boreholes and surfaces. The machine extends the basic VMC 450 MT machine design with two additional axes, indexing axis B in the milling spindle and a Y-axis in the working spindle. These additional axes allow even complex geometries to be produced and make the VMC 450-5 MT a genuine high-performance production center for chucked parts.

This machining center retains the basic features of the VMC series, meaning that heavy-duty machining processes and turning work with a high chip removal rate can be completed without any problems. This makes it possible to perform complete machining cycles from raw to finished part without the need for reclamping. Not only does this result in excellent machining times, it also ensures maximum component quality since it eliminates the possibility of reclamping errors. The extensive tool magazine contributes to the high productivity of the machine because retooling processes are minimized and the machine running times are therefore maximized. Quality control is taken care of by probes and measuring bridge circuits.

Technical Data

| VMC 300 MT | VMC 450 / 450 MT | VMC 450-4 | VMC 450-5 MT | VMC 600 / 600 MT | ||

|---|---|---|---|---|---|---|

| Chuck diameter | mm inch | 315 12.5 | 450 18 | 450 18 | 450 18 | 630 25 |

| Weight, max. | kg lb | 300 661 | 300 661 | 300 661 | 300 661 | 500 1,102 |

| Swing diameter over base | mm inch | 500 19.5 | 700 27.5 | 700 27.5 | 700 27.5 | 800 31.5 |

| Turning diameter, max. | mm inch | 300 12 | 450 18 | 450 18 | 450 18 | 600 24 |

Travel distance (*optional) | ||||||

| >> X1 / Y1 / Z1 | mm inch | 340 / - / 480 13.5 / - / 19 | 630 / - / 500 25 / - / 20 | 395 / 50* / 810 15.5 / 2* / 32 | 780 / - / 500 30.5 / - / 20 | 780 / - / 500 30.5 / - / 20 |

| >> X2 / Y2 / Z2 | mm inch | - / - / - - / - / - | - / - / - - / - / - | 395 / 50* / 810 15.5 / 2* / 32 | - / - / - - / - / - | - / - / - - / - / - |

| Main spindle | ||||||

| >> Spindle flange to ISO 702-1: 2009 | Size | 8 | 8 / 11 | 8 / 11 | 8 / 11 | 8 / 11 |

| >> Spindle bearing diameter | mm inch | 140 / 160 5.5 / 6.5 | 140 / 160 / 190 5.5 / 6.5 / 7.5 | 140 / 160 / 190 5.5 / 6.5 / 7.5 | 140 / 160 / 190 5.5 / 6.5 / 7.5 | 140 / 160 / 190 5.5 / 6.5 / 7.5 |