News & Media

06/30/2025 - Oliver Hagenlocher - Press

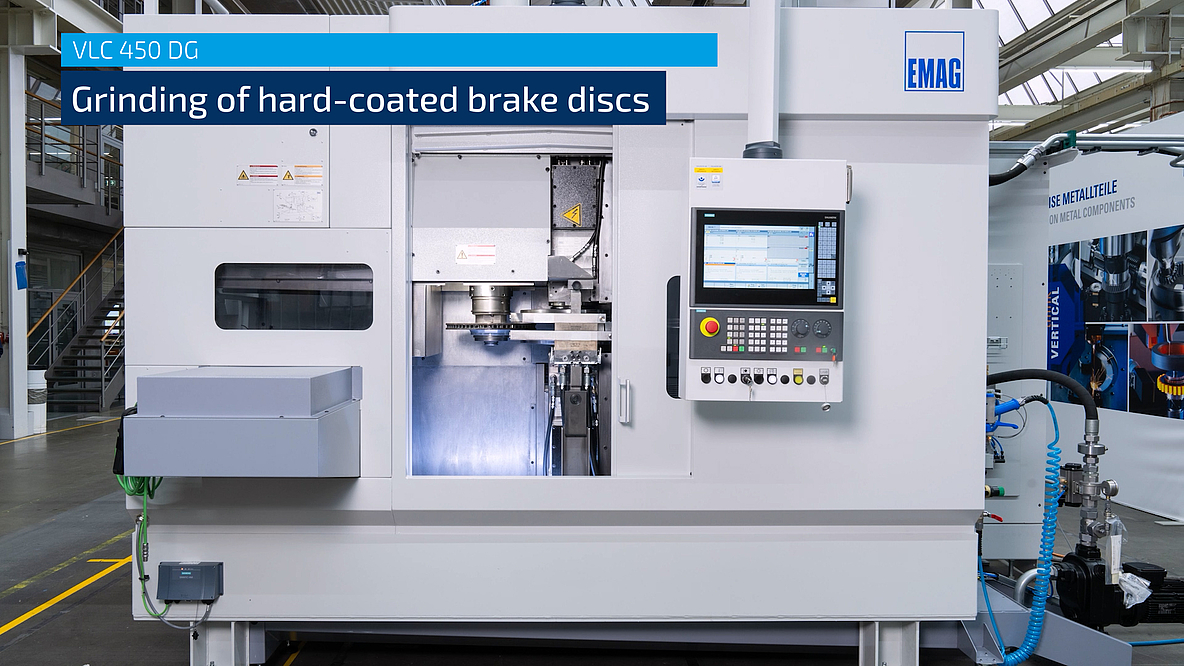

VLC 450 DG from EMAG: Perfecting the coated car brake disc in the grinding processThe car brake disc of the future is coated - the only way to meet the stricter particulate matter limits of the Euro 7 standard. The braking surface is also protected against corrosion and wear. But which machining process can guarantee that this quality can be achieved reliably in large quantities?…

05/28/2025 - Oliver Hagenlocher - Press

Comprehensive machining expertise: EMAG VL lathes in the PENN GmbH production chainThe increasing complexity of requirements in metal processing and international cost pressure pose particular challenges for manufacturing companies in high-wage countries. The Austrian company PENN GmbH has established itself as an internationally active metal processor through a high level of…

04/29/2025 - Oliver Hagenlocher - Press

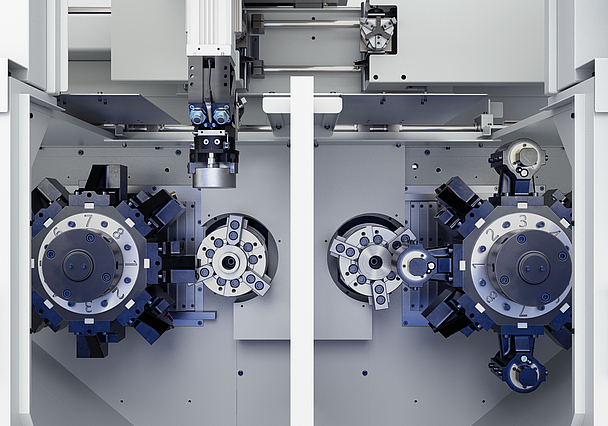

MSC 5 DUO: Front-loading CNC turning center for economical soft turningIn today's world, manufacturing companies are facing major challenges: increasing cost pressure, a shortage of skilled workers and rising energy costs. This combination requires machine tools that generate more output with less manpower and are energy-efficient at the same time. The MSC 5 DUO from…

EMAG Blog

Our video highlights

We have new videos for you! Our preview list shows you all new EMAG video highlights.